Autotrophic denitrification deep denitrification device and method for low-carbon-source sewage

An autotrophic denitrification and deep denitrification technology, which is applied in the field of low-carbon source sewage autotrophic denitrification deep denitrification devices, can solve the problems of high sulfate concentration in the effluent, easy outflow of sulfur, and long start-up time. Long, reduce the concentration of sulfate radicals in the effluent, and reduce the effect of starting time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

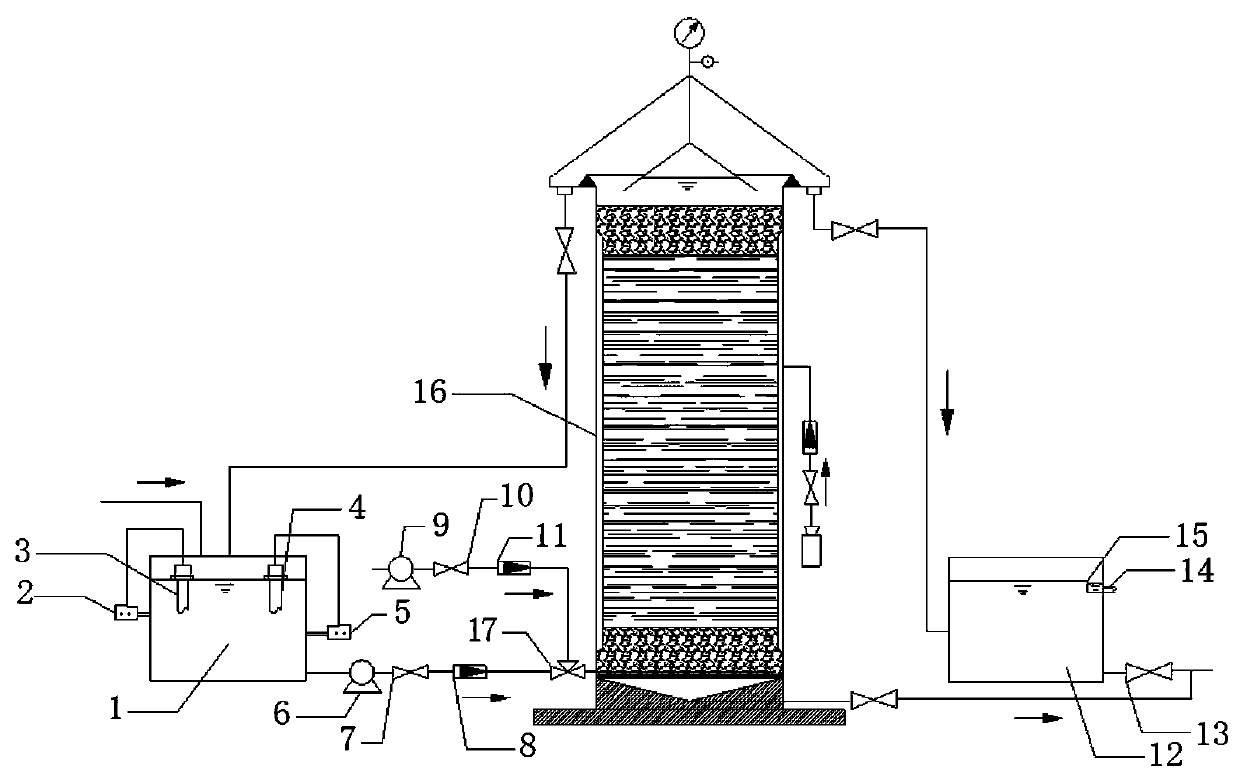

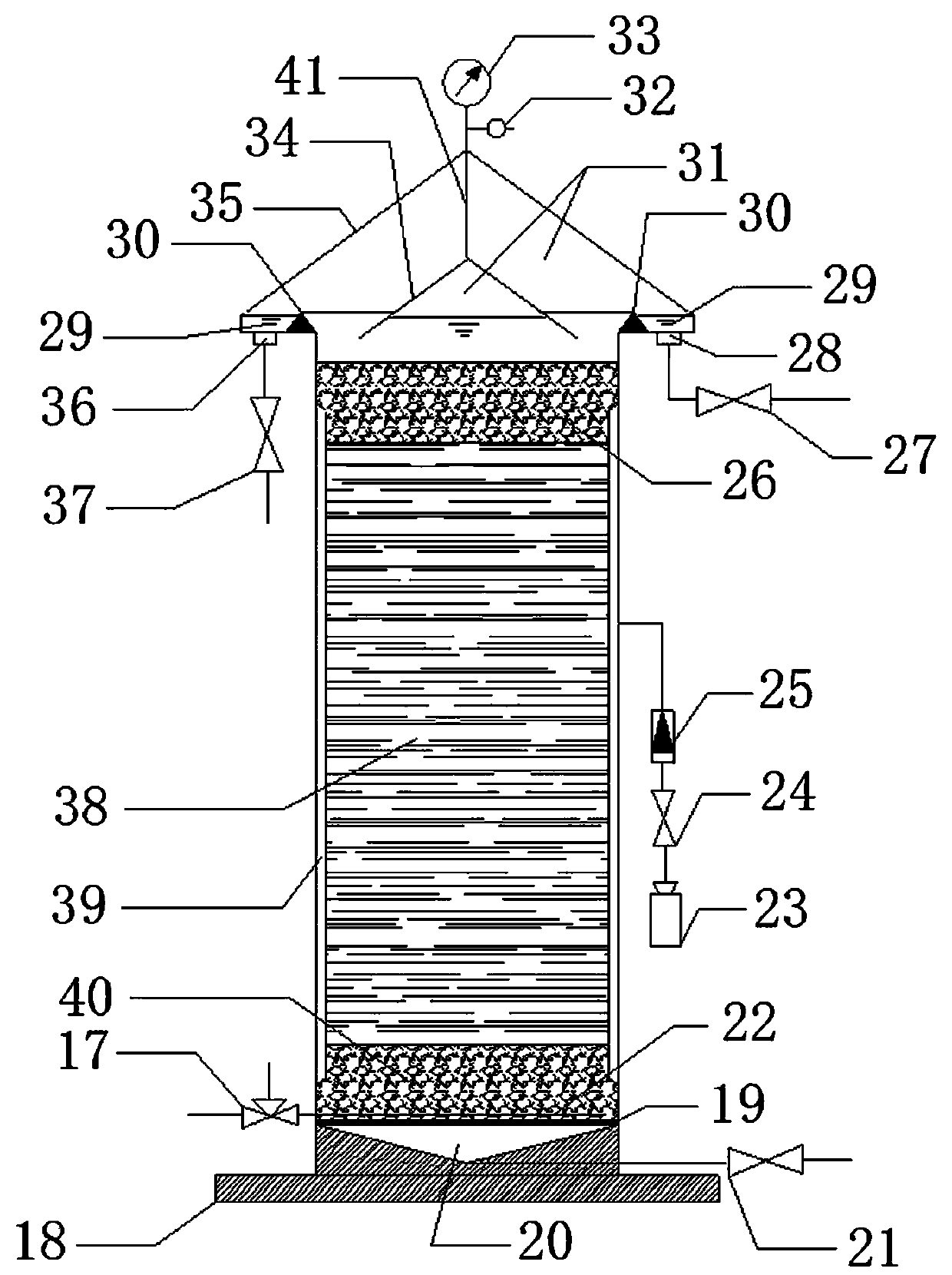

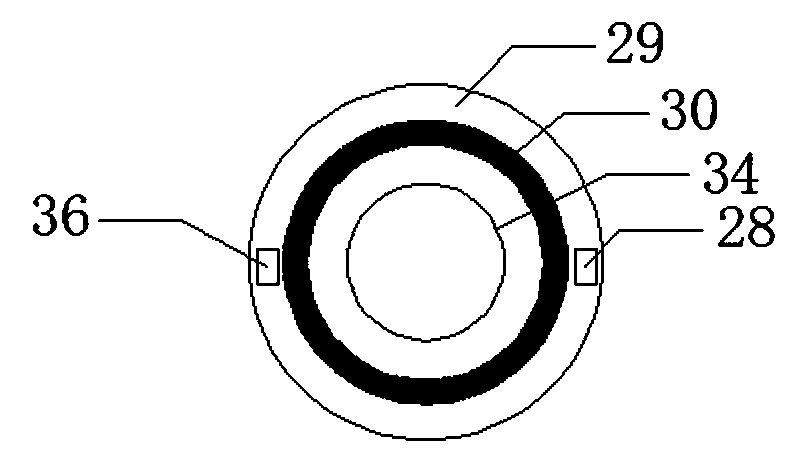

[0043] figure 1 A schematic structural diagram of the low-carbon source sewage autotrophic denitrification deep denitrification device of this embodiment is shown. The device includes a regulating tank 1, a reactor 16, and a sedimentation tank 12. The regulating tank 1 is provided with a pH probe 3 and a dissolved oxygen probe 4. The pH probe 3 is connected to the pH automatic control system 2, and the dissolved oxygen probe 4 Connected to the dissolved oxygen automatic control system 5, the pH automatic control system 2 is used to monitor the pH of the sewage in the adjustment tank 1, and the dissolved oxygen automatic control system 5 is used to monitor the dissolved oxygen concentration of the sewage in the adjustment tank 1.

[0044] The bottom of the regulating tank 1 is provided with a water outlet, and the bottom of the reactor 16 is provided with a water inlet. The water outlet of the regulating tank 1 and the water inlet of the reactor 16 are connected by a pipeline, ...

Embodiment 2

[0056] On the basis of the low-carbon source sewage autotrophic denitrification device in Example 1, this embodiment is a low-carbon source sewage autotrophic denitrification method. The method includes a start-up phase and an operation phase. The specific steps are as follows: :

[0057] Startup phase:

[0058] S101: Sewage enters the adjustment tank 1 from the water inlet of the adjustment tank 1, adjusts the water quality and water volume of the system, adjusts the pH of the inlet water by the pH automatic control system 2 to maintain it at 7.0-8.0, and adjusts the dissolved oxygen automatic control system 5 to adjust the dissolution of the inlet water The oxygen concentration is 0.5-1.5 mg / L, and an appropriate amount of trace element solution that is beneficial to the reproduction of autotrophic denitrifying bacteria is added. By creating an environment conducive to the growth and reproduction of autotrophic denitrifying bacteria, the film can be formed faster and the sy...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com