GH4720Li alloy, smelting method thereof, GH4720Li alloy component and aeroengine

A technology of aero-engines and smelting methods, applied in the direction of engine components, machines/engines, liquid fuel engines, etc., can solve the unfavorable GH4720Li alloy purity and metallurgical quality stability control, limit the GH4720Li alloy purity, lack of operating guidelines and evaluation standards and other problems, to achieve the effect of increasing the stirring effect, high fatigue life, and reducing the content of impurities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

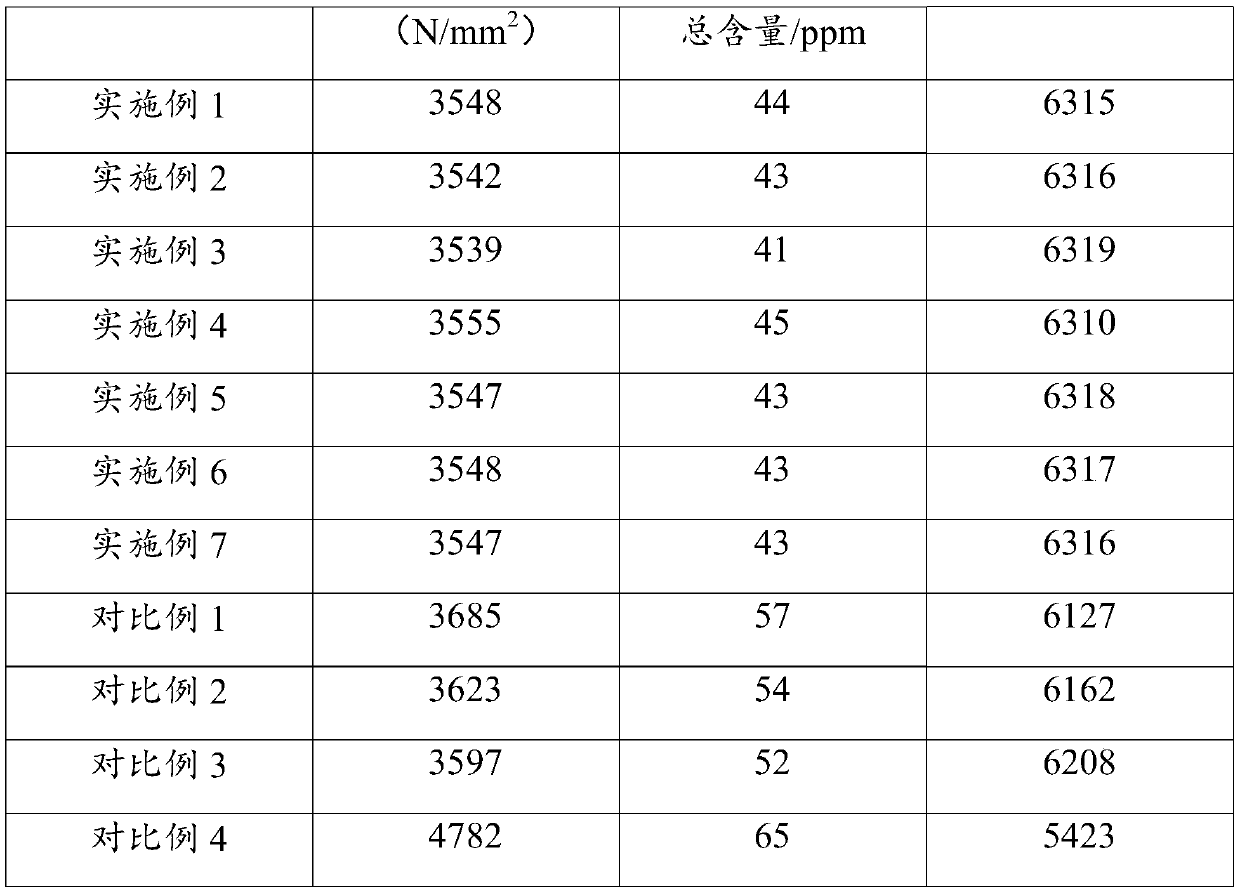

Examples

Embodiment 1

[0065] The smelting method of GH4720Li alloy comprises the following steps:

[0066] 1. Ingredients: According to the GH4720Li alloy composition control requirements, the amount of raw materials for each element is calculated according to the mass percentage;

[0067] 2. Material preparation: select nickel plate, cobalt plate, metal chromium, molybdenum bar, tungsten bar, ferroboron, graphite electrode, aluminum, titanium and zirconium, all raw materials need to be clean and free of oil;

[0068] 3. Loading: nickel plates and cobalt plates are randomly loaded into the bottom of the furnace, tungsten strips and molybdenum strips are placed in the middle of the crucible of the vacuum induction furnace, and the intermediate alloy is placed on it;

[0069] 4. High vacuum: the vacuum induction furnace is vacuumed to 30Pa;

[0070] 5. Melting period: the complete melting temperature of the alloy material is 1530°C;

[0071] 6. Refining period: After the alloy material is fully mel...

Embodiment 2

[0076] The smelting method of the GH4720Li alloy is the same as in Example 1, except that in step 6, if the absolute value of the change rate of the gas leakage rate measured twice adjacently is 4.5%-5%, the refining is stopped.

Embodiment 3

[0078] The smelting method of the GH4720Li alloy is the same as in Example 1, except that in step 6, if the absolute value of the change rate of the air leakage rate measured twice adjacently is 1.5%-2%, the refining is stopped.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com