Dielectric layer, ion capacitive flexible tactile sensor and preparation method and application thereof

A tactile sensor and dielectric layer technology, applied in the field of sensors, can solve the problems of inability to achieve high sensitivity and pressure resolution, capacitive signal cannot be further increased, and pressure response range is narrow, achieving low detection limit, fast response time, Effects with a wide response range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

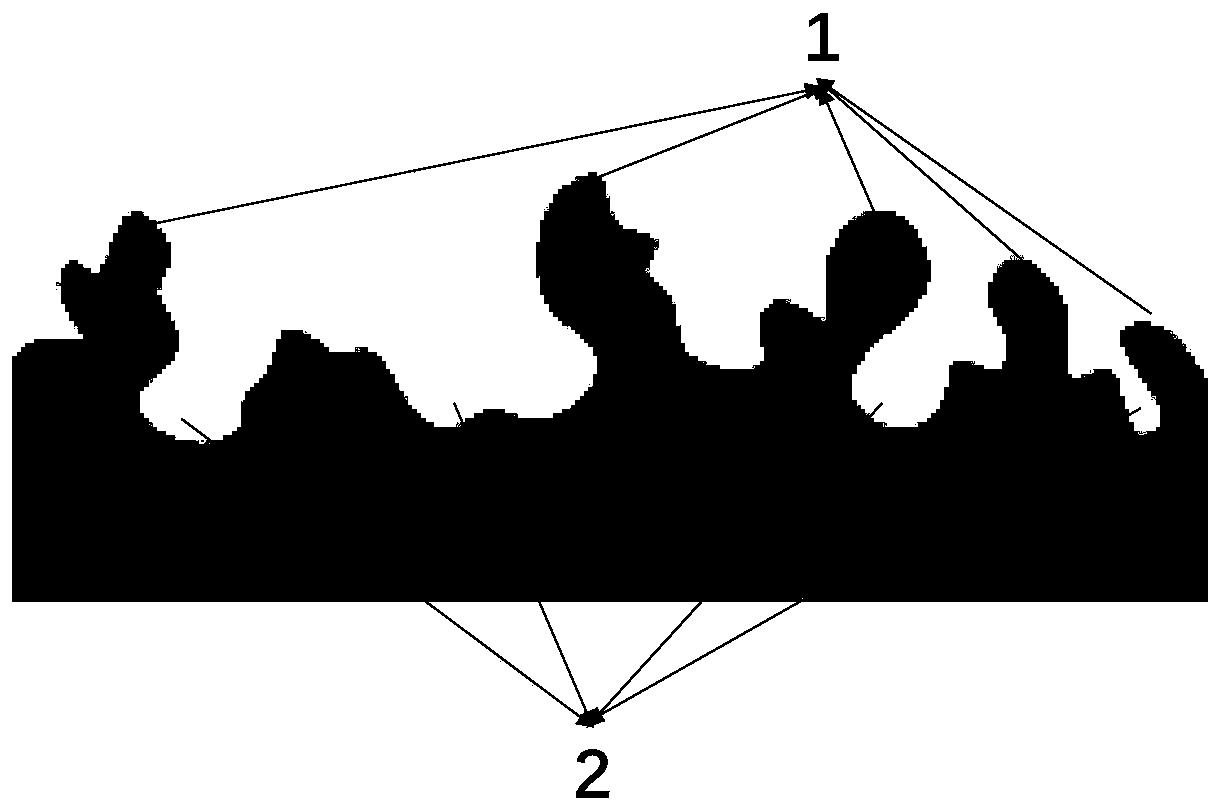

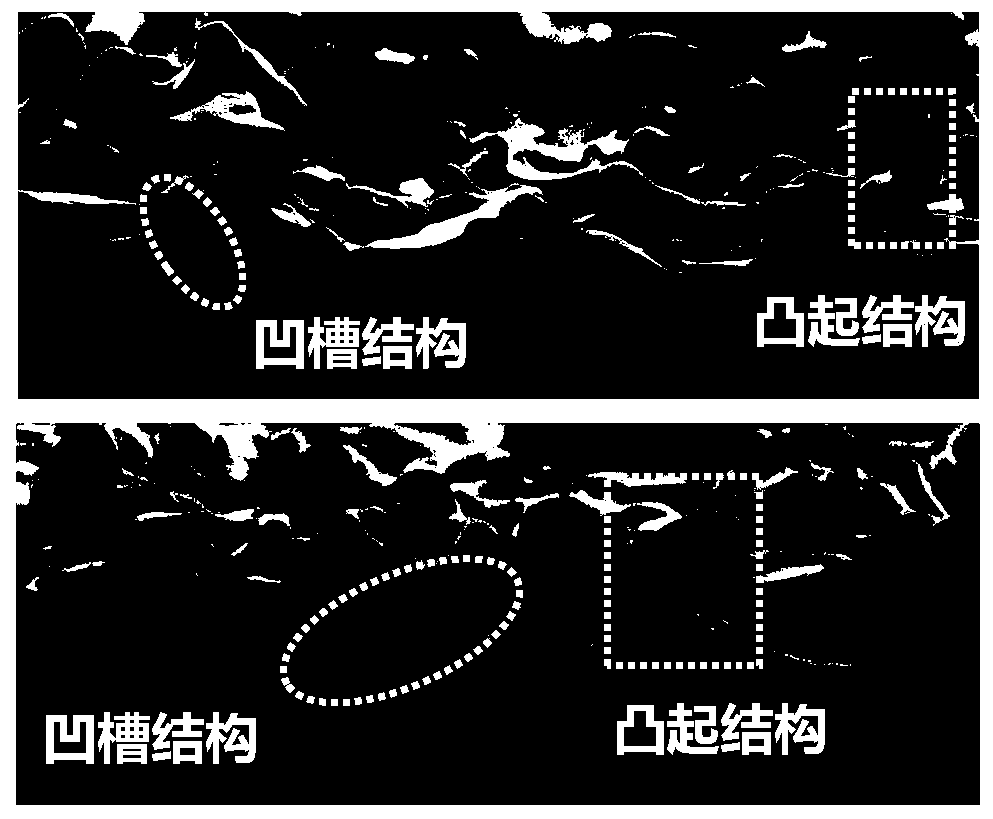

[0075] This embodiment provides a dielectric layer with a structure such as figure 1 As shown, one side of the dielectric layer is provided with at least two protruding structures 1 of different micron sizes, and one side of the dielectric layer is also provided with a groove structure 2 for receiving pressure A convex structure 1 pressed in; wherein the dielectric layer is a composite layer of polyvinyl alcohol / phosphoric acid.

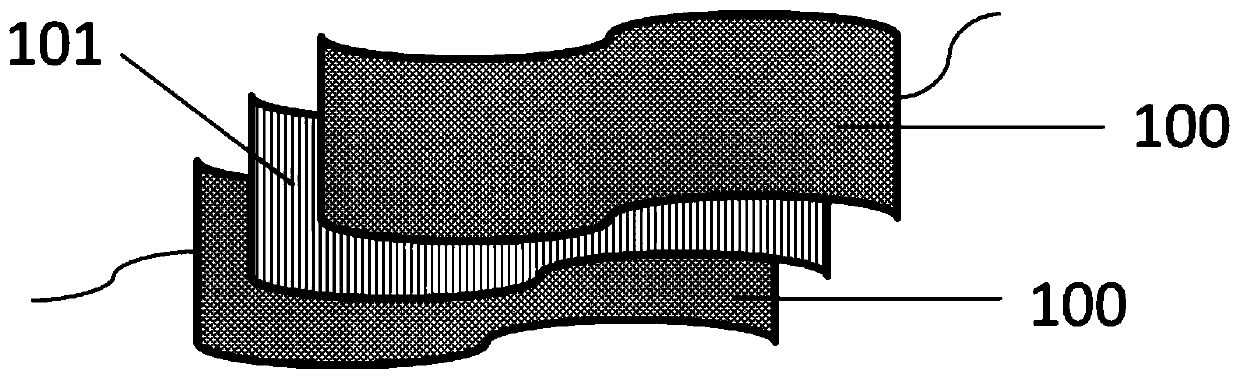

[0076] This embodiment also provides an ion capacitive flexible touch sensor, such as figure 2 As shown, it includes a dielectric layer 101 and electrode layers 100 disposed on both sides of the dielectric layer 101; wherein the electrode layer includes a PI / Au layer and leads connected to the PI / Au layer.

[0077] The preparation method of ion capacitive flexible tactile sensor comprises:

[0078] (1) The preparation method of the electrode layer includes: using a PI film with a thickness of 50 μm as a substrate, and using an electron beam evapor...

Embodiment 2

[0085] This embodiment provides a dielectric layer, one side of the dielectric layer is provided with at least two protruding structures with different micron sizes, and one side of the dielectric layer is also provided with a groove structure, the groove structure is used The raised structure is pressed in under the action of receiving pressure; the dielectric layer is a composite layer of polyvinyl alcohol / phosphoric acid.

[0086] This embodiment also provides an ion capacitive flexible touch sensor, which includes a dielectric layer and electrode layers arranged on both sides of the dielectric layer; wherein the electrode layer includes a PI / Au layer and leads connected to the PI / Au layer.

[0087] The preparation method of ion capacitive flexible tactile sensor comprises:

[0088] (1) The preparation method of the electrode layer includes: using a PI film with a thickness of 40 μm as a substrate, and using an electron beam evaporation method to evaporate a 100 nm thick Au...

Embodiment 3

[0093] This embodiment provides a dielectric layer, one side of the dielectric layer is provided with at least two protruding structures with different micron sizes, and one side of the dielectric layer is also provided with a groove structure, the groove structure is used The raised structure is pressed in under the action of receiving pressure; the dielectric layer is a composite layer of polyvinyl alcohol / phosphoric acid.

[0094] This embodiment also provides an ion capacitive flexible touch sensor, which includes a dielectric layer and electrode layers arranged on both sides of the dielectric layer; wherein the electrode layer includes a PI / Au layer and leads connected to the PI / Au layer.

[0095] The preparation method of ion capacitive flexible tactile sensor comprises:

[0096] (1) The preparation method of the electrode layer includes: using a PI film with a thickness of 100 μm as a substrate, and using an electron beam evaporation method to evaporate a 100 nm thick A...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com