Photocatalytic evaluation characterization device and method for carbon dioxide reduction

A carbon dioxide and carbon monoxide technology, which is used in measurement devices, chemical analysis by catalysis, instruments, etc., can solve the problems of cumbersome process flow, increase production cost, short service life, etc., and achieve simple process operation, simple installation and layout, The effect of low input cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

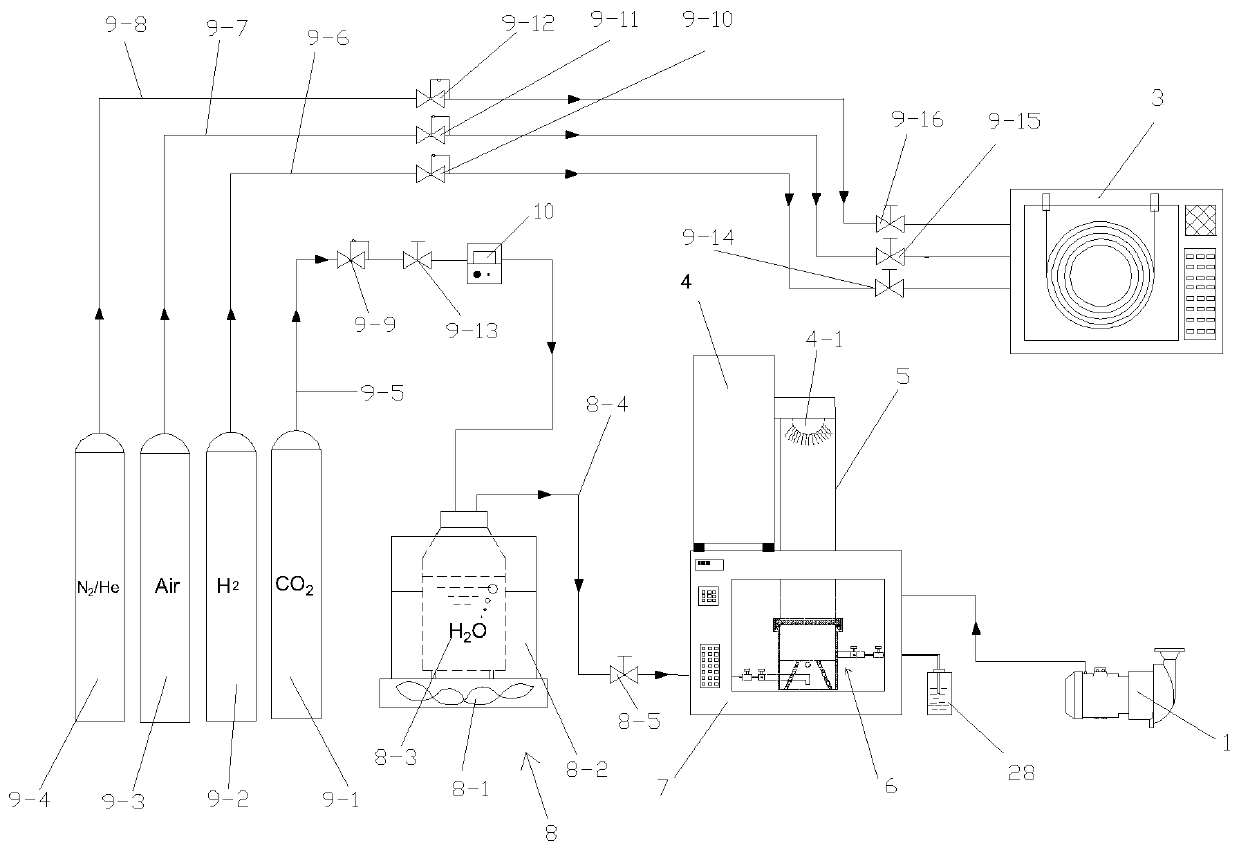

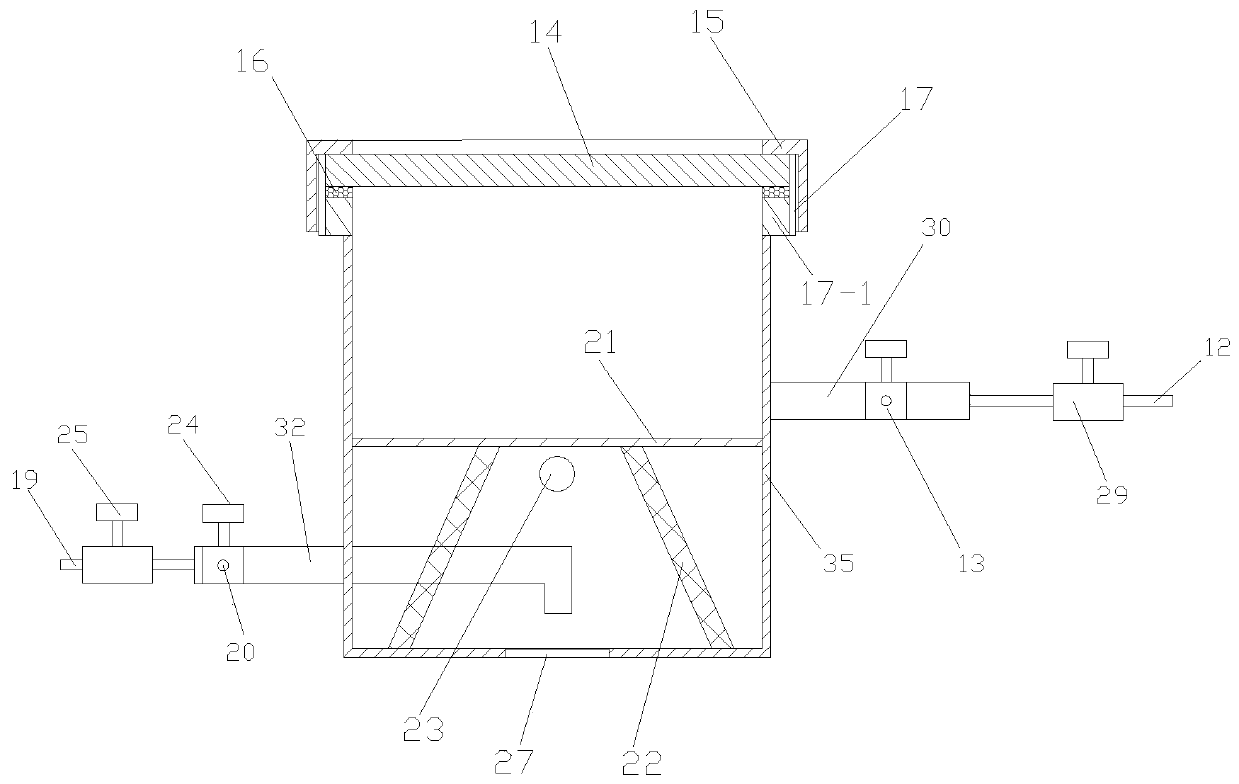

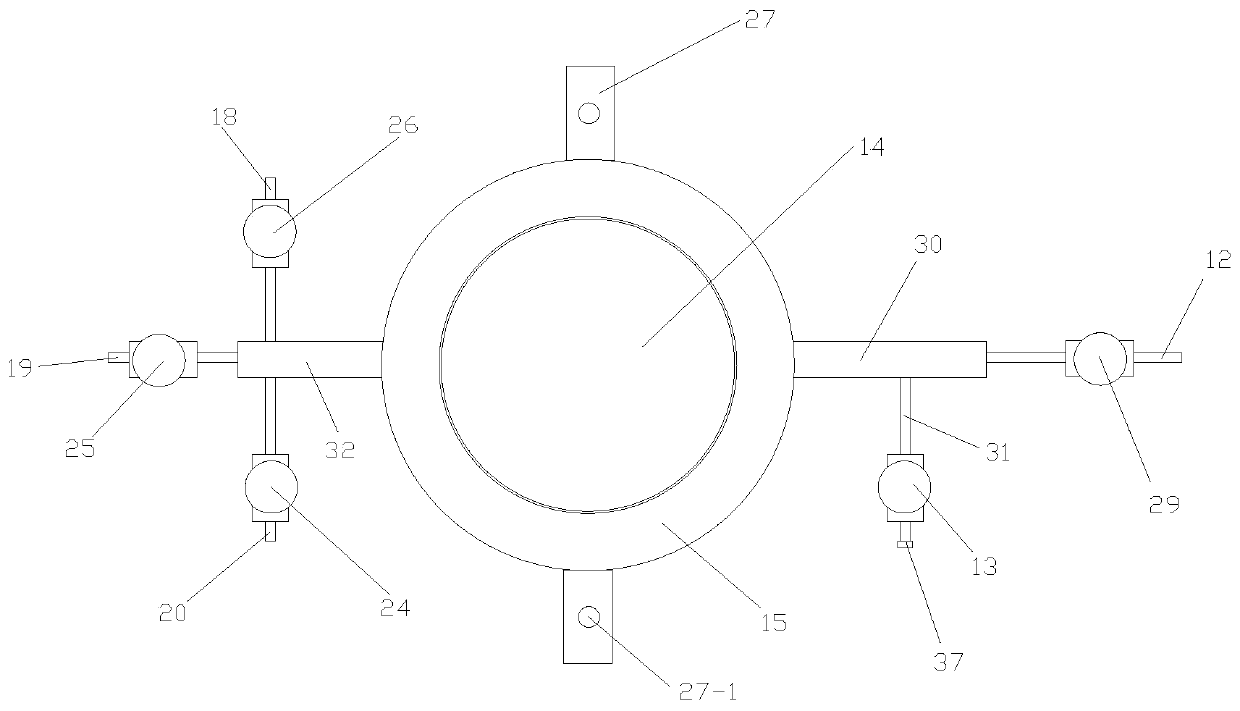

[0092] like Figure 1 to Figure 3 The shown photocatalytic evaluation and characterization device for carbon dioxide reduction includes a photocatalytic mechanism, a gas path mechanism, a water vapor generating mechanism 8 and a gas chromatograph 3, and the photocatalytic mechanism includes a blast drying box 7, which is arranged in a blast drying oven. The light source parts on the top of the box 7 and the catalytic reactor 6 arranged in the blast drying box 7, and the vacuum pump 1 connected with the catalytic reactor 6, the catalytic reactor 6 includes a reaction tank, is arranged in the reaction tank The four-corner support frame for placing photocatalyst and the inlet pipeline parts and outlet pipeline parts arranged on the reaction tank, the four-corner support frame includes activated carbon carrier net 21 for placing photocatalyst and four symmetrically arranged on activated carbon carrier The support leg 22 at the bottom of the net 21, the bottom of the support leg 22...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com