Microwave modified inorganic cementing material, and preparation method and application thereof

An inorganic cementitious material and microwave modification technology, applied in the field of inorganic cementitious materials, can solve the problems of poor sheet strength, inability to take into account high strength and light weight, and strength gap, etc., achieving low cost, significant improvement in product strength, The effect of simple ingredients of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

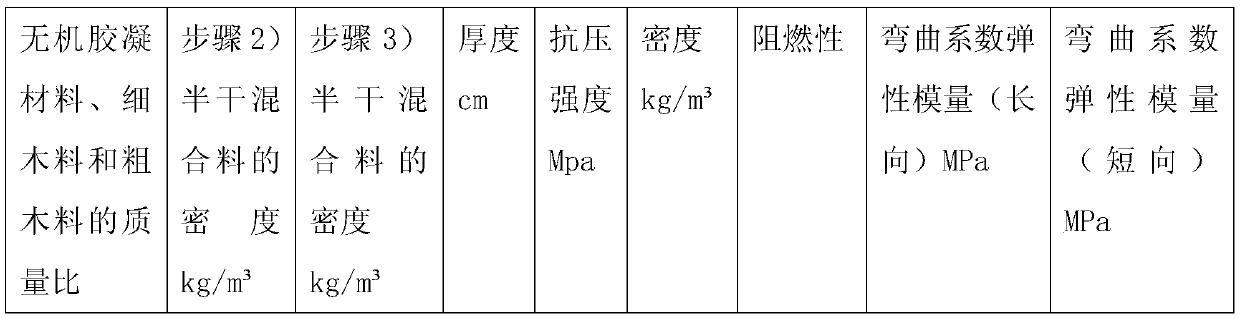

Examples

Embodiment 1

[0025] The raw material components of microwave-modified inorganic cementitious materials include: 25 parts of sulfoaluminate cement (525 sulfoaluminate cement, Onoda), 40 parts of water, 25 parts of silicon micropowder (1000 mesh), sodium silicate solution (molecule The number is 2.2-2.3M, Jiashan Yourui Refractory Co., Ltd.) 10 parts, cellulose (Hercules EH02) 0.5 parts, lithium oxide 1 part, industrial latex powder (Wacker industrial latex powder 4115N) 1.5 parts, air-entrained 0.2 part of agent (Germany Degussa 655), the parts are parts by mass;

[0026] The preparation method of microwave modified inorganic gelling material comprises the following steps:

[0027] 1) Mixing sulfoaluminate cement, silica micropowder and industrial latex powder into powder;

[0028] 2) mixing water, sodium silicate solution, cellulose and lithium oxide into a liquid material;

[0029] 3) Add the air-entraining agent to the liquid material obtained in step 1), and then add the powder obtain...

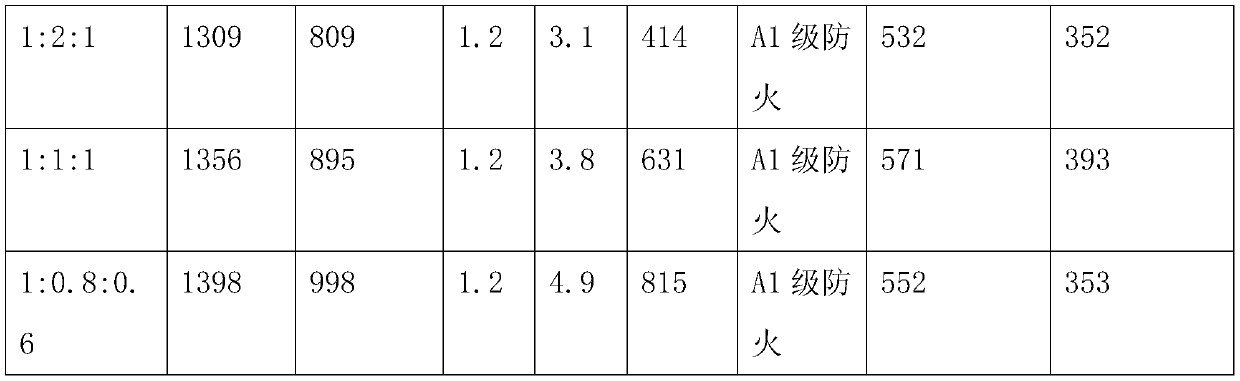

Embodiment 2

[0041] The raw material components of microwave modified inorganic cementitious materials include: 45 parts of sulphoaluminate cement (525 sulphoaluminate cement, Onoda), 40 parts of water, 45 parts of silicon micropowder (1000 mesh), sodium silicate solution (molecule The number is 2.2-2.3M, Jiashan Yourui Refractories Co., Ltd.) 12 parts, cellulose (Hercules EH02) 0.6 parts, lithium oxide 1 part, industrial latex powder (Wacker industrial latex powder 4115N) 1.5 parts, air-entrained Agent (Germany Degussa 655) 2.5 parts, said parts are parts by mass; the preparation of microwave modified inorganic gelling material refers to Example 1.

[0042] The above-mentioned microwave-modified inorganic gelling material was stirred with polyphenylene particles (Changzhou Kangnai Thermal Insulation Building Materials Co., Ltd.) and microwave-modified inorganic gelling material for 20 minutes under microwave irradiation with a power of 20kw, and then poured into the The iron box mold with...

PUM

| Property | Measurement | Unit |

|---|---|---|

| modulus | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com