Adhesive and preparation method thereof, pressure-sensitive adhesive tape and preparation method thereof

A pressure-sensitive adhesive tape and adhesive technology, applied in the direction of adhesives, pressure-sensitive film/sheet, film/sheet-shaped adhesives, etc., can solve the problems of poor heat resistance of pressure-sensitive adhesives, leaving adhesive residue, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0042] The present invention also provides a kind of preparation method of adhesive, and it comprises the steps:

[0043] S1. Weigh each raw material component according to the corresponding parts by mass.

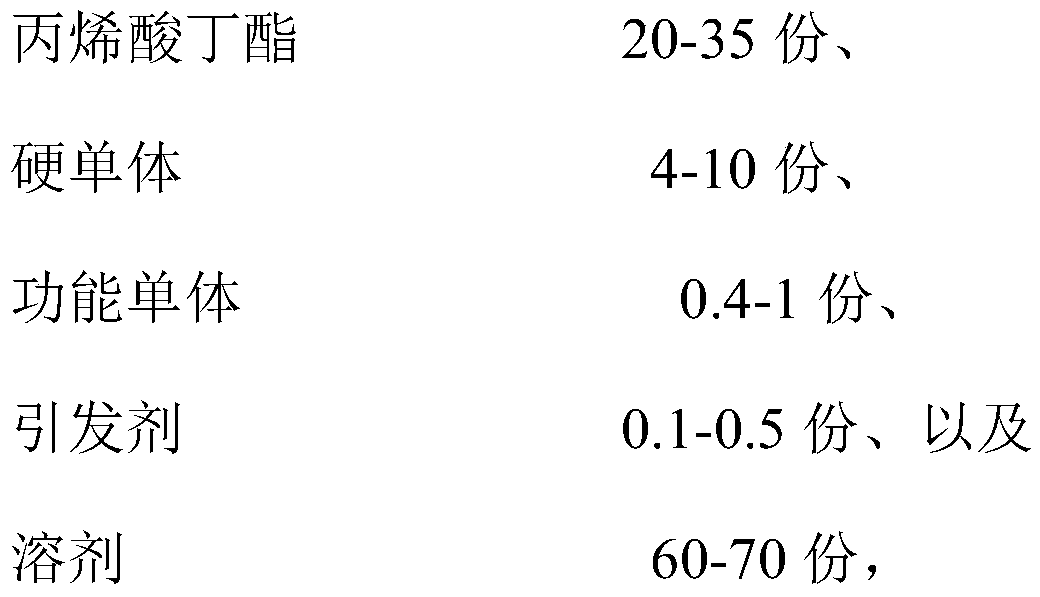

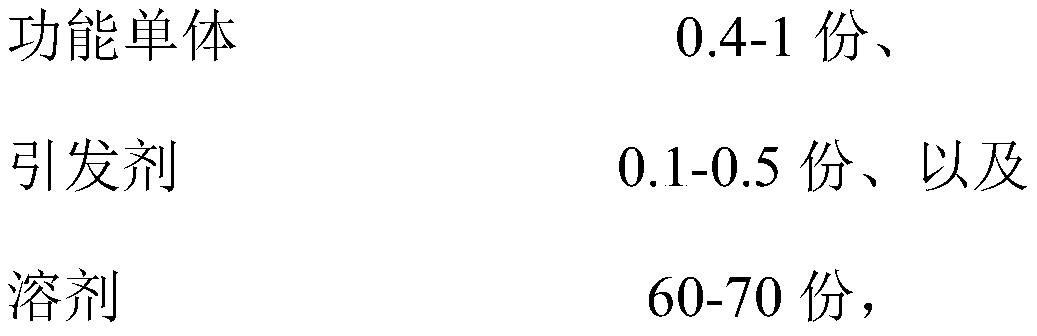

[0044] Wherein, each raw material composition ratio is as follows:

[0045]

[0046] The hard monomer is selected from at least two of methyl acrylate, methyl methacrylate and glycidyl methacrylate, and the functional monomer is selected from at least two of hydroxyethyl acrylate, acrylic acid and acrylamide , and the functional monomer needs to contain hydroxyethyl acrylate.

[0047] S2. Mix butyl acrylate, hard monomers, functional monomers and a part of the solvent to obtain a mixture.

[0048] Mix the butyl acrylate, the hard monomer, the functional monomer and a part of the solvent until uniform, and further, mix the butyl acrylate, the hard monomer, the functional monomer and a part of the solvent until uniform by stirring. Further, the addition amount of this ...

Embodiment 1

[0073] A preparation method of high temperature resistant acrylate adhesive, it comprises the steps:

[0074] 229 g of butyl acrylate, 15 g of hydroxyethyl acrylate, 35 g of methyl acrylate, 15 g of glycidyl methacrylate, 3 g of acrylic acid, 3 g of acrylamide, 80 g of toluene, and 320 g of ethyl acetate were charged into the reactor. Under the condition of stirring, pass nitrogen gas to remove the air in the reactor, put in 0.3g of azobisisobutyronitrile, 66-67°C, keep the temperature for 2 hours; continue to put in 0.5g of azobisisobutyronitrile, Keep the temperature and react for 3 hours; add 0.8g of azobisisobutyronitrile, and keep the temperature for 2 hours under the condition of 78-80°C; cool and add 300g of solvent ethyl acetate to obtain a high temperature resistant acrylate adhesive.

Embodiment 2

[0076] A preparation method of high temperature resistant acrylate adhesive, it comprises the steps:

[0077] 217 butyl acrylate, 21 g of hydroxyethyl acrylate, 35 g of methyl acrylate, 20 g of glycidyl methacrylate, 3.5 g of acrylic acid, 3.5 g of acrylamide, 100 g of toluene, and 300 g of ethyl acetate were charged into the reactor. Under the condition of stirring, pass nitrogen gas to remove the air in the reactor, put in 0.2g of azobisisobutyronitrile, 66-67°C, keep the temperature for 2 hours; continue to put in 0.4g of azobisisobutyronitrile, Keep the temperature and react for 3 hours; continue to add 0.8g of azobisisobutyronitrile, and keep the temperature for 2 hours under the condition of 78-80°C; cool and add 300g of ethyl acetate as a solvent to obtain a high temperature resistant acrylate adhesive.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com