Viscoelastic nano-magnetic fluid for improving crude oil recovery ratio of tight reservoir, and preparation method thereof

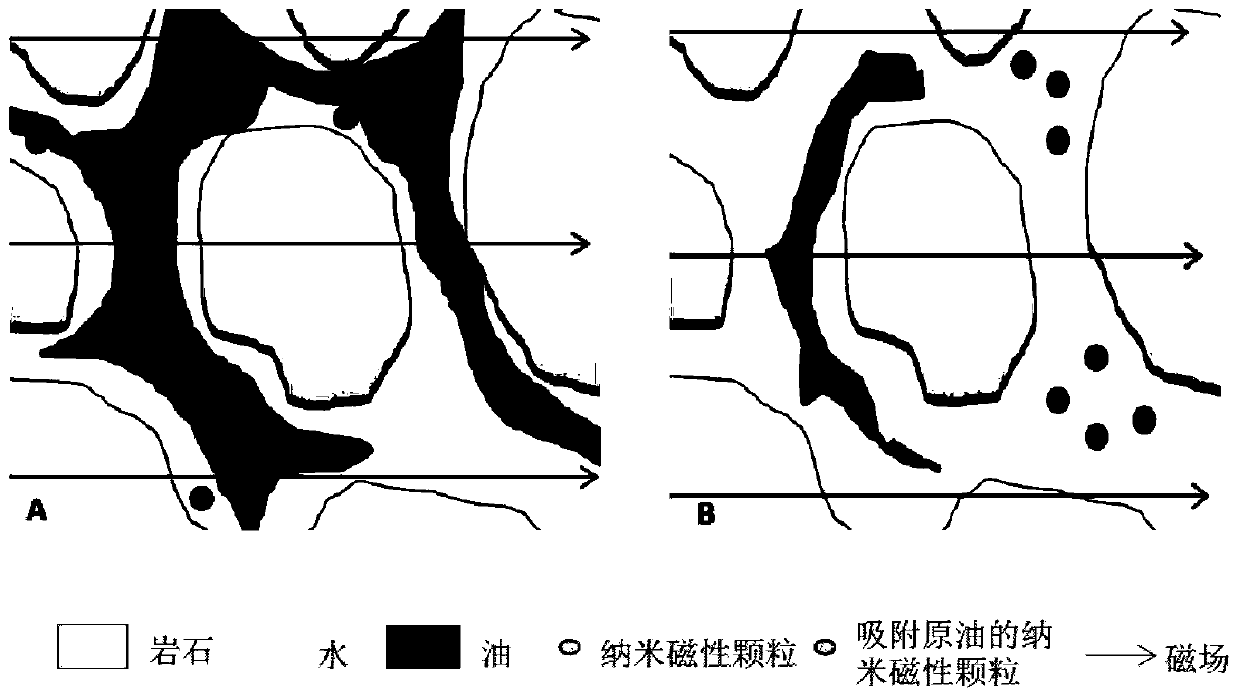

A technology of nano-magnetic fluid and tight reservoir, which is applied in the direction of nano-technology, mining fluid, and nano-technology for materials and surface science, can solve the problems of crude oil nano-magnetic fluid and preparation technology without tight reservoir, and achieve improvement The effect of oil recovery, strong stability and strong lipophilicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

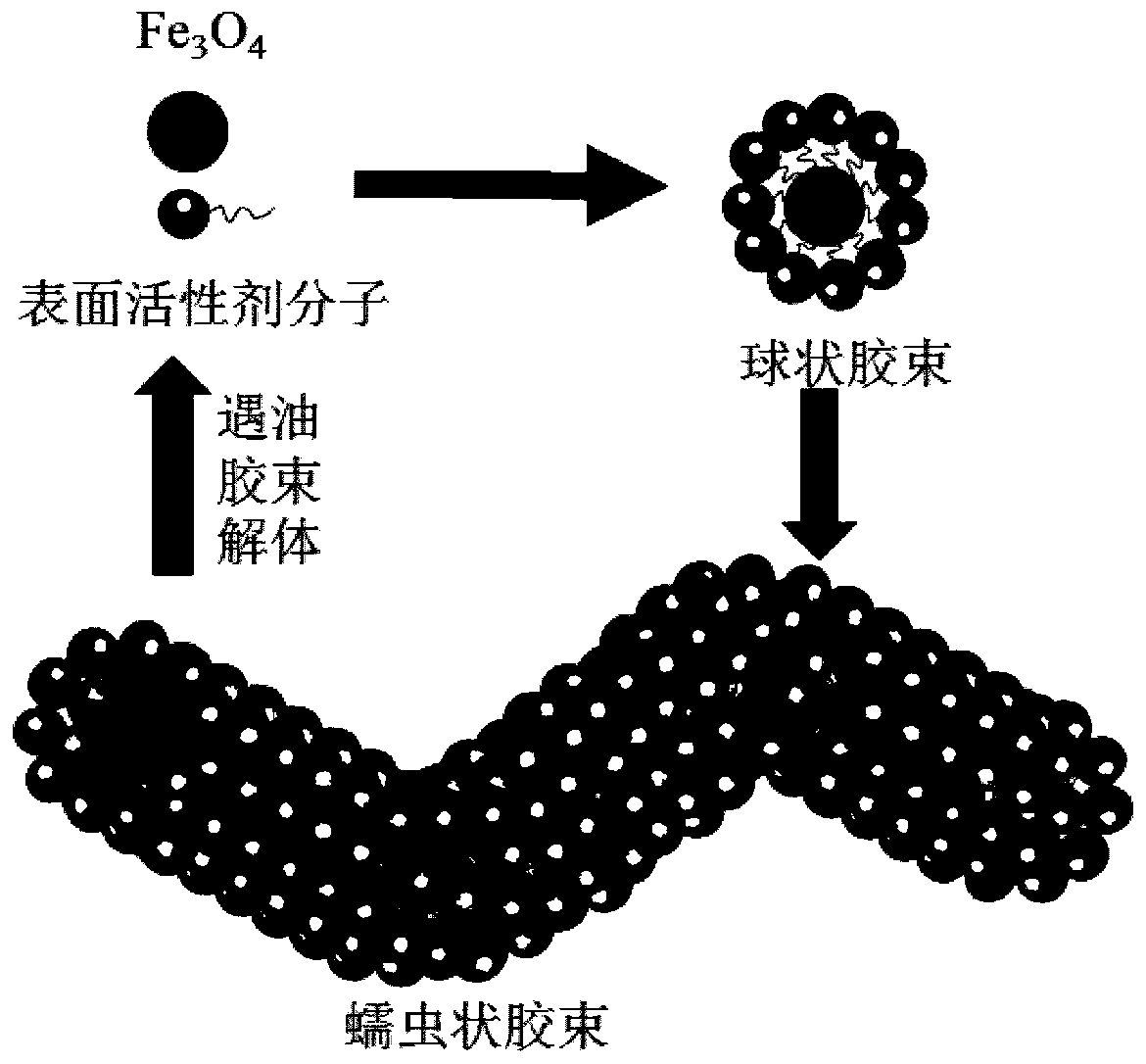

[0046] A preparation method of viscoelastic nano magnetic fluid for improving oil recovery in tight reservoirs, including the following steps:

[0047] (1) Put 16.2g FeCl 3 And 13.9g FeSO 4 ·7H 2 O was dissolved in 200 mL of deionized water and stirred evenly to obtain a mixed solution. The mixed solution was heated to 60°C, and 0.1 mol / L NaOH solution was added while stirring to adjust the pH of the system to 10, and then reacted for 40 minutes for precipitation to obtain Fe 3 O 4 Particles

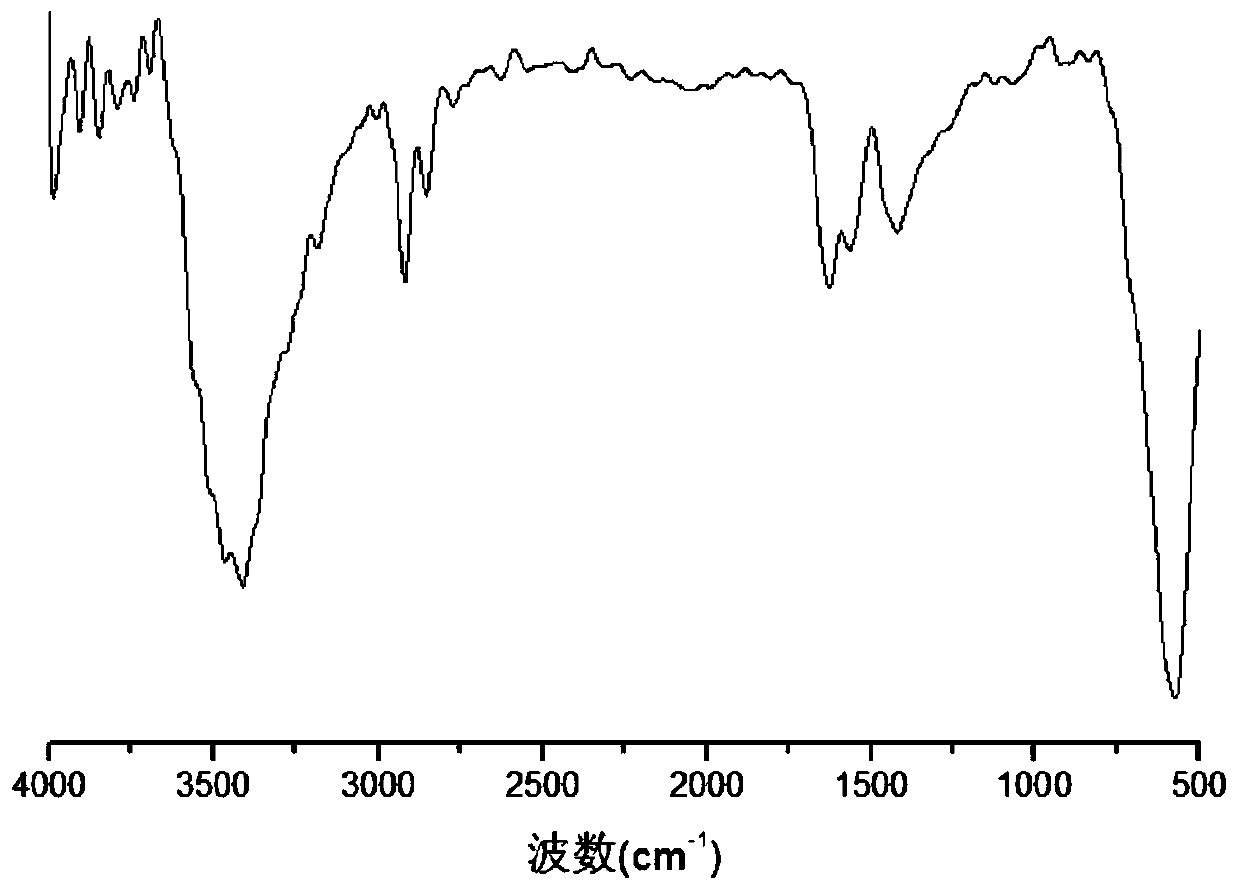

[0048] (2) Dissolve 4.56 g of sodium oleate in 100 mL of deionized water to obtain a sodium oleate solution, and add the sodium oleate solution to step (1) to obtain Fe 3 O 4 The granules are aged for 2 hours under the conditions of a mechanical stirring rate of 500r / min and a aging temperature of 95°C, and they are naturally cooled to room temperature. The solid particles are separated, washed with deionized water 5 times, and dried at 75°C in vacuum for 4 hours. Obtain Fe modified by sodium ...

Embodiment 2

[0053] A preparation method of viscoelastic nano-magnetic fluid used to improve the oil recovery of tight reservoirs is as described in Example 1, except that in step (3), 1.49g is chlorinated at a temperature of 60°C Sodium and 1.52g sodium oleate were dissolved in 100mL deionized water, stirred for 30min, and naturally cooled to room temperature to obtain a viscoelastic surfactant solution; take 3g of the sodium oleate modified Fe obtained in step (2) 3 O 4 The particles were added to the viscoelastic surfactant solution and stirred at a rate of 400r / min for 60 minutes to obtain a viscoelastic nano magnetic fluid.

[0054] The lipophilicity and magnetic response test results of the viscoelastic nanomagnetic fluid prepared in this embodiment are as follows Figure 5 As shown, a, viscoelastic nano magnetic fluid, b, viscoelastic nano magnetic fluid is added with kerosene (upper layer), c, nano magnetic particles enter the oil phase (upper layer), d, the oil phase containing nano ma...

Embodiment 3

[0056] A preparation method of viscoelastic nano-magnetic fluid for improving oil recovery in tight reservoirs is as described in Example 1, except that in step (3), at a temperature of 60°C, 3.18g of sodium carbonate And 1.83 g of sodium oleate were dissolved in 100 mL of deionized water, stirred for 30 minutes, and naturally cooled to room temperature to obtain a viscoelastic surfactant solution; take 2 g of the sodium oleate modified Fe obtained in step (2) 3 O 4 The particles were added to the viscoelastic surfactant solution and stirred at a rate of 400r / min for 60 minutes to obtain a viscoelastic nano magnetic fluid.

[0057] The transmission electron microscope (TEM) photo of the viscoelastic nanomagnetic fluid prepared in this example is as follows Image 6 Shown from Image 6 It can be seen that the size of the nanoparticles is about 20nm, the shape is consistent, and the dispersion is good.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com