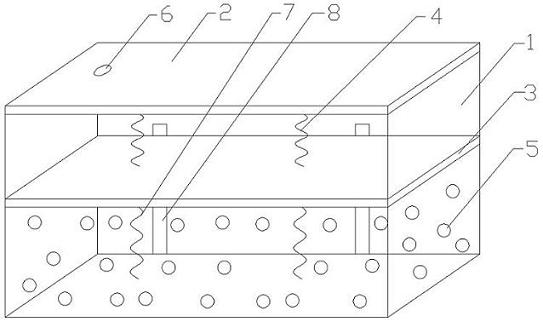

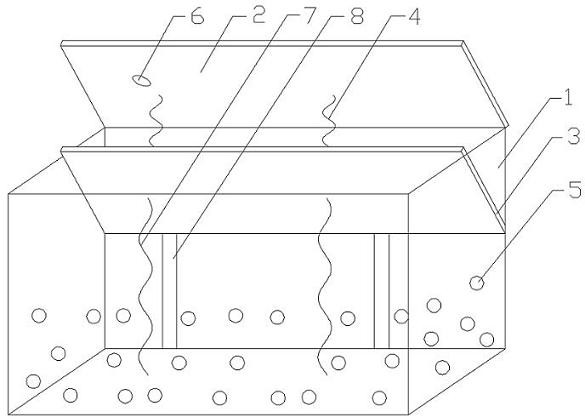

A container type aluminum electrode

An aluminum electrode and container technology, applied in the field of aluminum electrodes, can solve the problems of cumbersome and inconvenient replacement or maintenance steps, high corrosion rate, weak deoxidation ability, etc., so as to improve the continuous use time and durability, avoid chemical reactions, maintain Simple and convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] Embodiment 1: 9997 grams of aluminum, lanthanum oxide (La 2 o 3 ) 1.5 grams, indium oxide (In 2 o 3 ) 1.5 grams.

Embodiment 2

[0054] Embodiment 2: 9997 grams of aluminum, lanthanum oxide (La 2 o 3 ) 1.2 grams, praseodymium oxide (Pr 2 o 3 ) 0.8 g, indium oxide (In 2 o 3 )1 g.

Embodiment 3

[0055] Embodiment 3: 9995 grams of aluminum, lanthanum oxide (La 2 o 3 ) 1 g, cerium oxide (Ce 2 o 3 ) 0.3 g, praseodymium oxide (PrO 2 ) 1.2 g, indium oxide (In 2 o 3 ) 2.5 grams.

PUM

| Property | Measurement | Unit |

|---|---|---|

| corrosion rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com