Formula of facial cream having whitening function and production process

A functional and whitening technology, applied in the field of skin care products, can solve problems such as redness, allergies, strong irritation, etc., and achieve the effect of improving dull skin, easy absorption, and improving water-deficient state.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

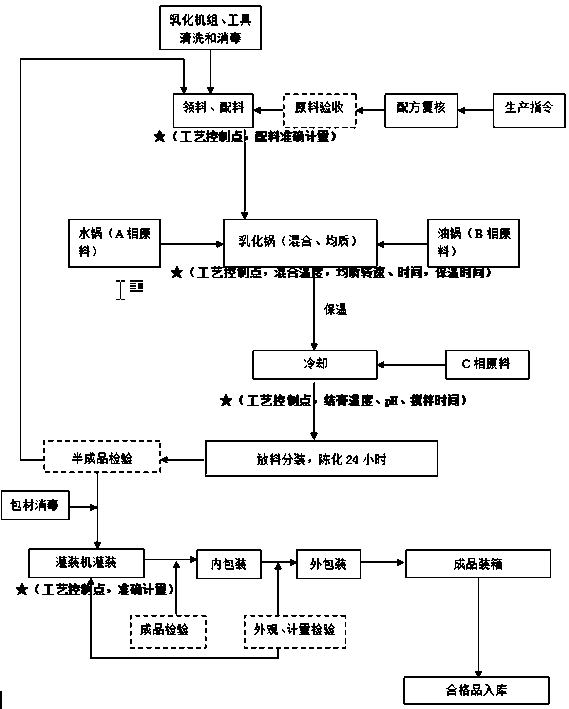

Method used

Image

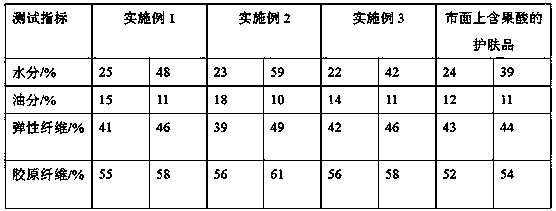

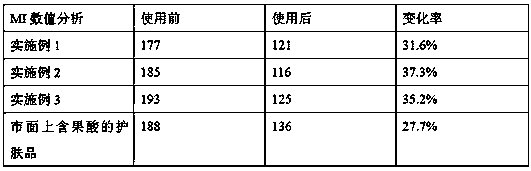

Examples

Embodiment 1

[0018] 1. Formula components: The raw materials used in component A include by weight: 20 parts of water, 2 parts of glycerin, and 5 parts of CAMELLIA SINENSIS tea extract; the raw materials used in component B include by weight: 2 parts of cetyl alcohol, 8 parts of mineral oil, 1 part of dimethicone, 1 part of sodium laureth-11 carboxylate, 1 part of vitamin E, 5 parts of squalane, 0.01 part of methylparaben, 0.01 part of propylparaben part; the raw materials used in component C include by weight: 0.01 part of menthol lactate, and 0.5 part of essence.

[0019] 2. Preparation method:

[0020] (1) Preparation before operation: check and accept the raw materials, and accurately weigh the dosage of each raw material according to the raw material formula; clean and disinfect the emulsification pot, water pot, oil pot and all the utensils required for production;

[0021] (2) Weigh and mix component A according to the formula components, then add to the water pot, heat to 75°C, an...

Embodiment 2

[0027] 1. Formula components: The raw materials used in component A include by weight: 25 parts of water, 6 parts of glycerin, and 9 parts of CAMELLIA SINENSIS tea extract; the raw materials used in component B include by weight: 3 parts of cetyl alcohol, 10 parts of mineral oil, 3 parts of dimethicone, 3 parts of sodium laureth-11 carboxylate, 3 parts of vitamin E, 8 parts of squalane, 0.02 parts of methyl paraben, 0.02 parts of propyl paraben part; the raw materials used in component C include by weight: 0.02 part of menthol lactate, and 0.8 part of essence.

[0028] 2. Preparation method:

[0029] (1) Preparation before operation: check and accept the raw materials, and accurately weigh the dosage of each raw material according to the raw material formula; clean and disinfect the emulsification pot, water pot, oil pot and all the utensils required for production;

[0030] (2) Weigh and mix component A according to the formula components, then add to the water pot, heat to ...

Embodiment 3

[0036] 1. Formula components: The raw materials used in component A include by weight: 30 parts of water, 7 parts of glycerin, and 9 parts of CAMELLIA SINENSIS tea extract; the raw materials used in component B include by weight: 7 parts of cetyl alcohol, 12 parts of mineral oil, 5 parts of dimethicone, 5 parts of sodium laureth-11 carboxylate, 3 parts of vitamin E, 10 parts of squalane, 0.05 parts of methyl paraben, 0.03 parts of propyl paraben Parts; The raw materials used in component C include by weight parts: 0.03 parts of menthol lactate and 1 part of essence.

[0037] 2. Preparation method:

[0038] (1) Preparation before operation: check and accept the raw materials, and accurately weigh the dosage of each raw material according to the raw material formula; clean and disinfect the emulsification pot, water pot, oil pot and all the utensils required for production;

[0039] (2) Weigh and mix component A according to the formula components, then add to the water pot, he...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com