Preparation method of whole body glazed brick and whole body glazed brick

A glazed brick, whole body technology, applied in the direction of manufacturing tools, supply devices, ceramic molding machines, etc., can solve the problems of insufficient authenticity, inability to penetrate the decorative patterns, discontinuous patterns, etc., and achieve the effect of enhancing the decorative effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

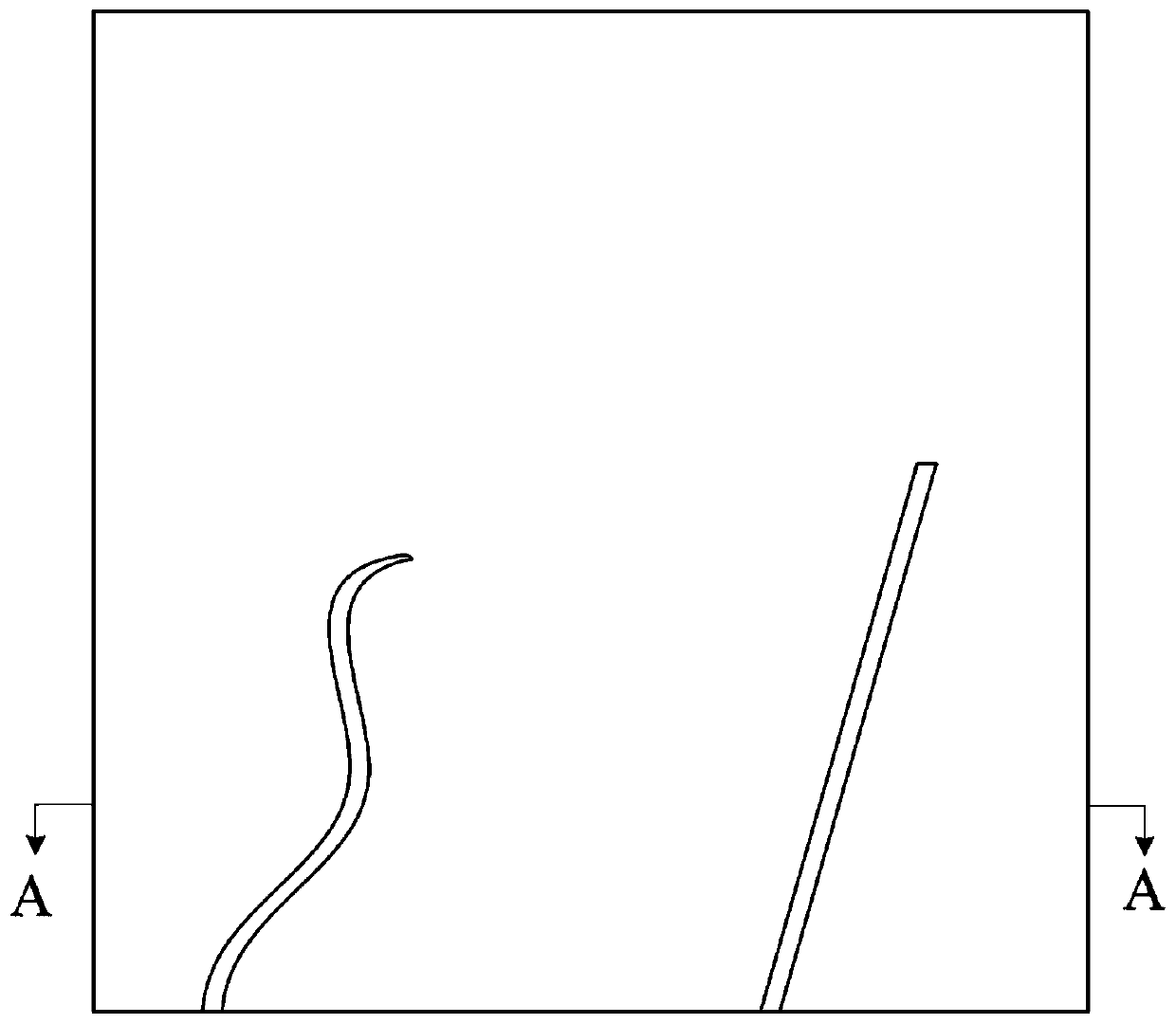

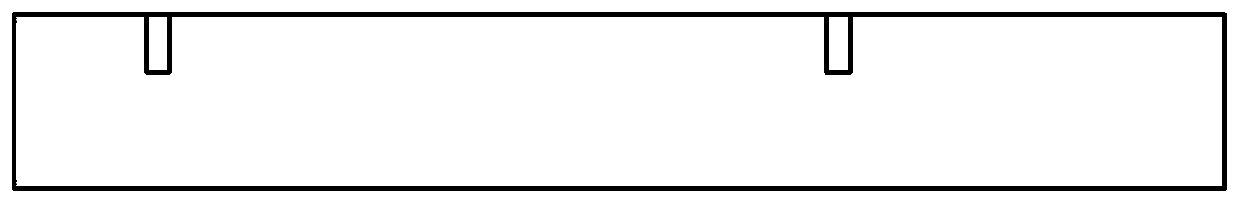

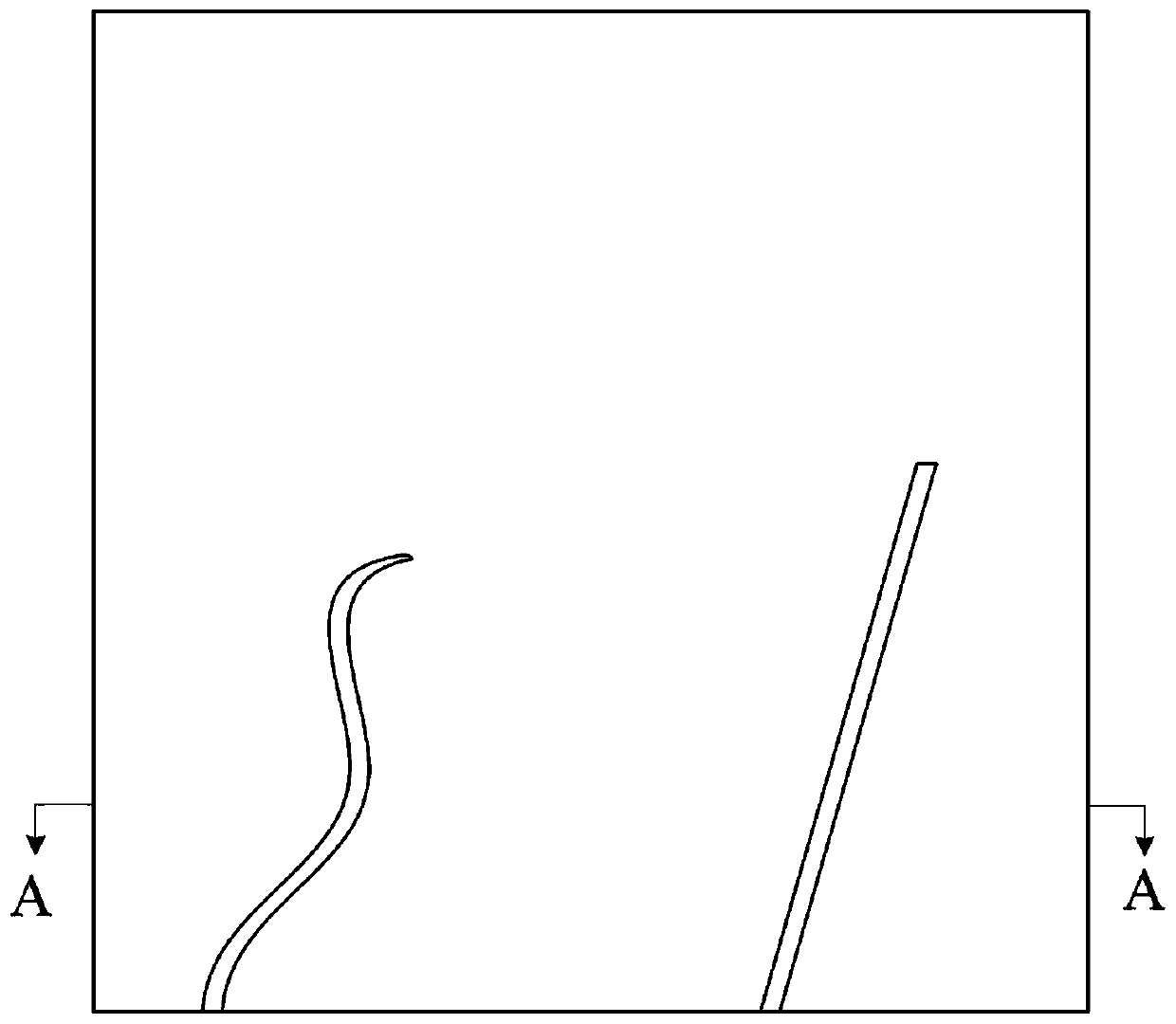

[0039] see Figure 1 ~ Figure 2 , the whole body brick produced by the existing inkjet bleeding technology, its pattern can not penetrate the whole brick body, after cutting, the decorative effect is poor. For this reason, the invention provides a kind of preparation method of whole body glazed tile, it comprises the following steps:

[0040] (1) The cloth machine and inkjet printer obtain the pattern information uploaded by the user;

[0041] Wherein, the pattern information is the surface pattern of the glazed tile, which can be the texture of the existing common imitation natural stone and marble; preferably, it is an imitation marble pattern; more preferably, it is a Carrara stone pattern; Carrara stone It has a basically uniform base color (white or yellow, etc.), but is interspersed with a small amount of gray / black texture. It is moist throughout, and the texture is relatively simple and easy to imitate.

[0042] Preferably, the pattern information includes first patt...

Embodiment 1

[0082] The present embodiment provides a kind of preparation method of full-body glazed tile, which comprises:

[0083] (1) The cloth machine and inkjet printer obtain the pattern information uploaded by the user;

[0084] (2) Provide powder and colorant, mix powder and colorant to obtain mixed powder;

[0085] (3) distributing the mixed powder to obtain a powder assembly;

[0086] (4) The distributing machine prints the first ink on the surface of the powder assembly according to the pattern information, and leaves it standing for 20s to fully penetrate the first ink; wherein, the first ink is water-based ink;

[0087] (5) Press the powder assembly that has been printed and infiltrated into a press to obtain a green body, wherein the molding pressure is 30Mpa;

[0088] (6) Dry the green body; adopt the existing drying process; the highest drying temperature is 220° C., and the drying time is 30 minutes (drying with wet flue gas for 10 minutes, drying with dry flue gas for 2...

Embodiment 2

[0097] The present embodiment provides a kind of preparation method of full-body glazed tile, which comprises:

[0098] (1) The cloth machine and inkjet printer obtain the pattern information uploaded by the user;

[0099] (2) Provide powder and colorant, mix powder and colorant to obtain mixed powder;

[0100] (3) distributing the mixed powder to obtain a powder assembly;

[0101] (4) The distributing machine prints dipropylene glycol methyl ether on the surface of the powder assembly according to the pattern information, and leaves standstill for 18s to fully penetrate the dipropylene glycol methyl ether;

[0102] The distributing machine prints the first ink on the surface of the powder assembly according to the pattern information, and stands still for 6s to fully penetrate the first ink; wherein, the first ink is water-based ink;

[0103] (5) Pressing the printed and infiltrated powder assembly into a press to obtain a green body, wherein the molding pressure is 30 MPa;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com