A method for preparing high-purity calcium fluoride from calcium fluoride sludge

Calcium fluoride and calcium fluoride technology are applied in the direction of calcium/strontium/barium fluoride, calcium/strontium/barium halide, etc., which can solve the problems of shortage of fluorine resources, achieve simple process, broad market application prospects, The effect of solving the shortage of fluorine resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

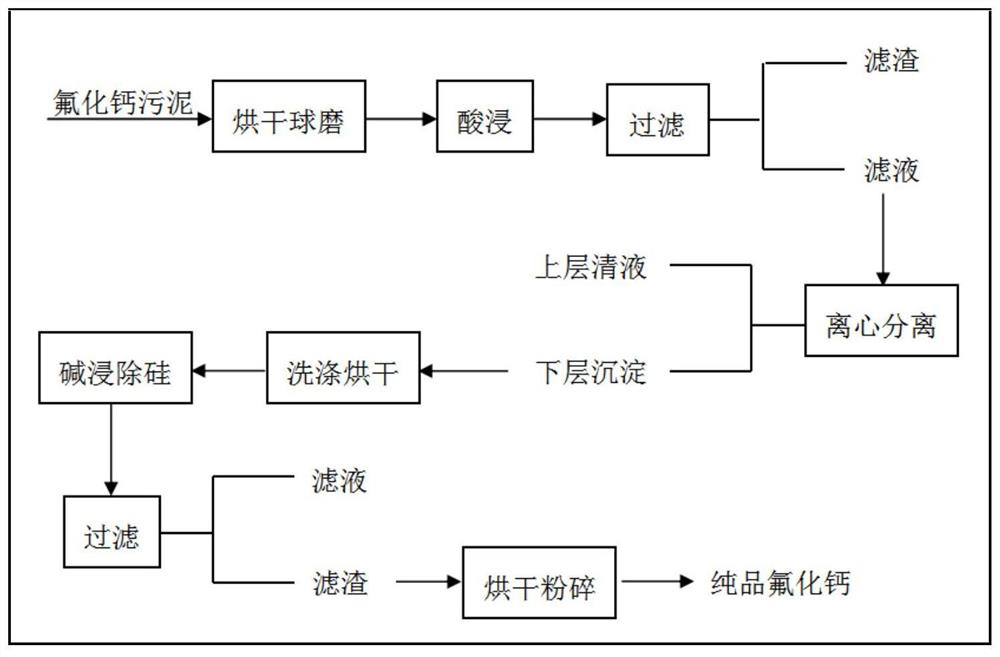

[0027] 1. Sludge drying: Put the calcium fluoride sludge into the oven to dry thoroughly, then ball mill it with a ball mill and sieve it with a 200-mesh sieve to obtain the undersize A;

[0028] 2. Sludge acidification: Weigh 10 g of the above-mentioned undersize material A and mix it with 60 mL of 2.0 mol / L hydrochloric acid solution, and stir it to react to obtain a solid-liquid mixture B;

[0029] 3. Filtration: Filter and sieve the solid-liquid mixture B with different filter cloths to obtain filter residue C and filtrate D;

[0030] 4. Centrifugation: The filtrate D was subjected to centrifugation washing, the centrifugation speed was 5000r / min, the centrifugation time was 15min, and the number of times of deionized water washing was 3 times to obtain the precipitate E;

[0031] 5. Alkali leaching to remove silicon: Weigh 8.7375g solid sodium hydroxide and add deionized water to dissolve to make 50mL sodium hydroxide solution with a mass fraction of 15%; weigh 10g of the...

Embodiment 2

[0034] 1. Sludge drying: Put the calcium fluoride sludge into the oven to dry thoroughly, then ball mill it with a ball mill and sieve it with a 200-mesh sieve to obtain the undersize A;

[0035] 2. Sludge acidification: Weigh 10 g of the above-mentioned undersize material A and mix it with 53.33 mL of 1.5 mol / L hydrochloric acid solution, and stir it to react to obtain a solid-liquid mixture B;

[0036] 3. Filtration: filter and sieve the solid-liquid mixture B with filter cloths of different meshes to obtain filter residue C and filtrate D;

[0037] 4. Centrifugation: The filtrate D was subjected to centrifugation washing, the centrifugation speed was 5000r / min, the centrifugation time was 15min, and the number of times of deionized water washing was 3 times to obtain the precipitate E;

[0038] 5. Alkali leaching to remove silicon: Weigh 12.191g of solid sodium hydroxide and add deionized water to dissolve to make 50mL of sodium hydroxide solution with a mass fraction of 20...

Embodiment 3

[0041] 1. Sludge drying: Put the calcium fluoride sludge into the oven and dry it thoroughly, then use a ball mill to grind it and sieve it with a 200-mesh sieve to obtain the undersize A;

[0042] 2. Sludge acidification: Weigh 100g of the above-mentioned undersize A and mix it with 600mL 2.0mol / L hydrochloric acid solution, and stir it evenly, dissolve the alkaline precipitate, and obtain a solid-liquid mixture B;

[0043] 3. Filtration: Filter and sieve the solid-liquid mixture B with different filter cloths to obtain filter residue C and filtrate D;

[0044] 4. Centrifugation: The above-mentioned filtrate D is subjected to centrifugation washing, the centrifugation speed is 5000r / min, the centrifugation time is 15min, and the number of times of deionized water washing is 3 times to obtain the precipitate E;

[0045]5. Alkali leaching to remove silicon: Weigh 7.5g of solid sodium hydroxide and add deionized water to dissolve to make 50mL of sodium hydroxide solution with a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com