Hydrogel, and preparation method and application thereof

A technology of hydrogel and gelatin solution, which can be applied in the direction of prosthesis, bandage, protein coating, etc., can solve problems such as difficult to apply, ignore material biocompatibility, complex and cumbersome material preparation process, etc., to achieve strong practicability and excellent Effect of biocompatibility and mechanical properties, good application effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

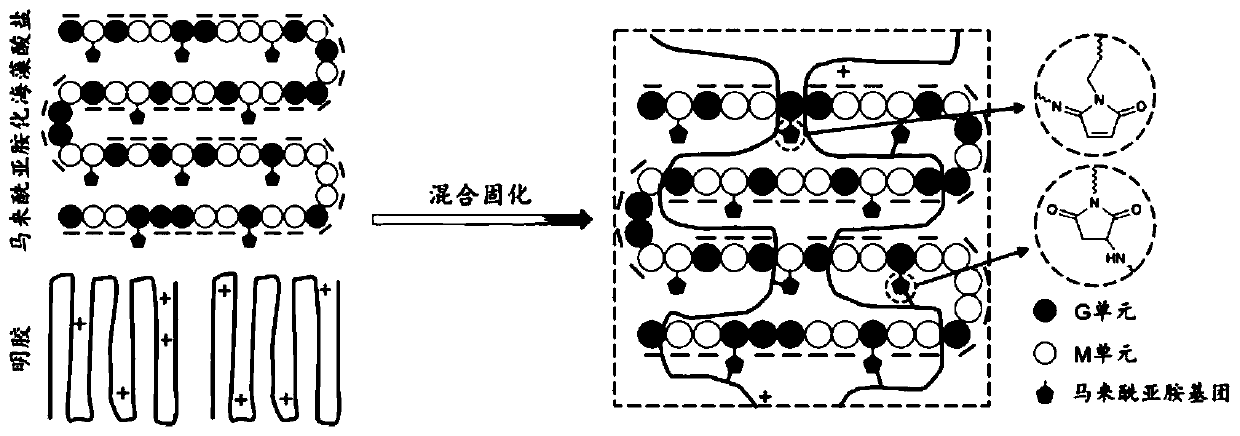

[0051] In a specific embodiment, the preparation method of the hydrogel of the present invention comprises the following steps:

[0052] (1) Dissolving maleimidated alginate in phosphate buffer, and adjusting the pH value to 7.0-8.0 to obtain a maleimidated alginate solution; wherein, the maleimidated alginate Alginate is alginate modified by maleimidation, and the modification rate is 5-15%;

[0053] (2) dissolving the gelatin in hot phosphate buffer solution, and adjusting the pH value to 7.0-8.0 to obtain a gelatin solution;

[0054] (3) The maleimidated alginate solution is mixed with the gelatin solution to form a hydrogel mixed solution, which is solidified to obtain the hydrogel.

[0055] Gelatin is partially degraded from collagen in connective tissues such as animal skin, bone, and sarcolemma. There are a large number of hydroxyl groups in the molecular structure of gelatin, and there are also many carboxyl groups and amino groups, which make gelatin extremely hydro...

Embodiment 1

[0065] The preparation of maleimidated alginate comprises the steps:

[0066] (1) Dissolve 4.2g of alginate in 100mL of phosphate buffer, then add 1.38g of 1-ethyl-(3-dimethylaminopropyl)carbodiimide hydrochloride and 0.52g of N-hydroxysulfosuccinate imide, activated at 25°C for 1 hour;

[0067] (2) Add 0.51 g of N-(2-aminoethyl)maleimide trifluoroacetate to the activated solution in step (1), and magnetically stir at room temperature for 6 hours of coupling reaction;

[0068] (3) After the reaction, adjust the pH value of the solution to 6.0 with hydrochloric acid; transfer the solution to a dialysis bag, and perform dialysis in a dilute hydrochloric acid solution with a pH of 5.0 for 3 days, collect the dialysate in the dialysis bag after the dialysis, and freeze Drying gave purified maleimidated alginate as a white solid.

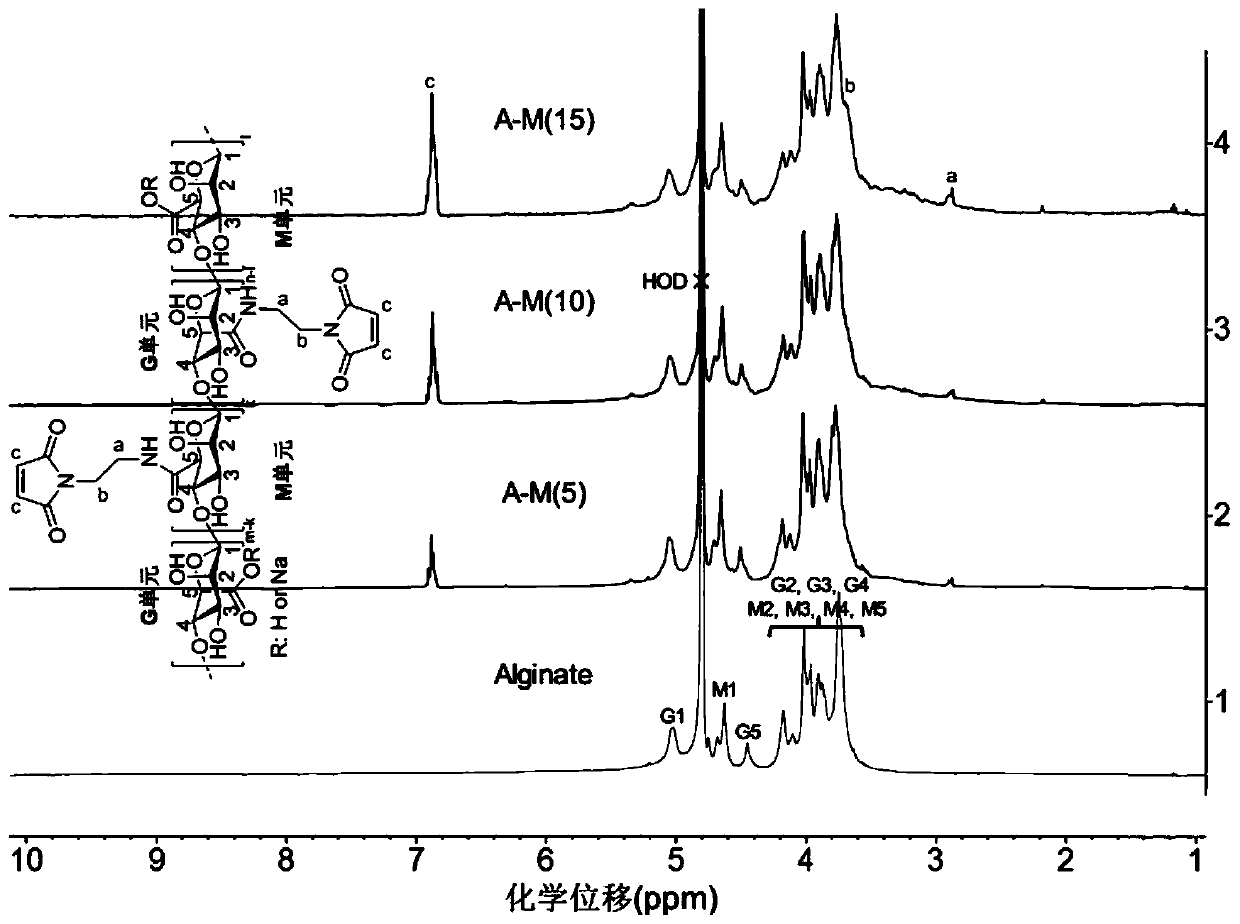

[0069] In the prepared maleimidated alginate, the modification rate of maleimidation was 5%. The H NMR spectrum of the prepared maleimidated alginate...

Embodiment 2

[0076] The preparation of maleimidated alginate comprises the steps:

[0077] (1) Dissolve 4.2g of alginate in 100mL of phosphate buffer, then add 2.76g of 1-ethyl-(3-dimethylaminopropyl)carbodiimide hydrochloride and 1.04g of N-hydroxysulfosuccinate imide, activated at 25°C for 1 hour;

[0078] (2) Add 1.02 g of N-(2-aminoethyl)maleimide trifluoroacetate to the activated solution in step (1), and magnetically stir at room temperature for 8 hours of coupling reaction;

[0079] (3) After the reaction is over, adjust the pH value of the solution to 5.0 with hydrochloric acid; transfer the solution to a dialysis bag, and perform dialysis in a dilute hydrochloric acid solution with a pH of 5.0 for 4 days, collect the dialysate in the dialysis bag after the dialysis, and freeze Drying gave purified maleimidated alginate as a white solid.

[0080] In the prepared maleimidated alginate, the maleimidated modification rate was 10%. The H NMR spectrum of the prepared maleimidated alg...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com