Three-cylinder tri-supporting crankshaft for diaphragm pump and processing technology

A technology for supporting shafts and diaphragm pumps, applied in the field of crankshafts in reciprocating pumps, can solve the problems of difficult processing and assembly processes, poor rigidity and strength, and high prices, and achieve simple processing and assembly processes, reduced assembly difficulty, and low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

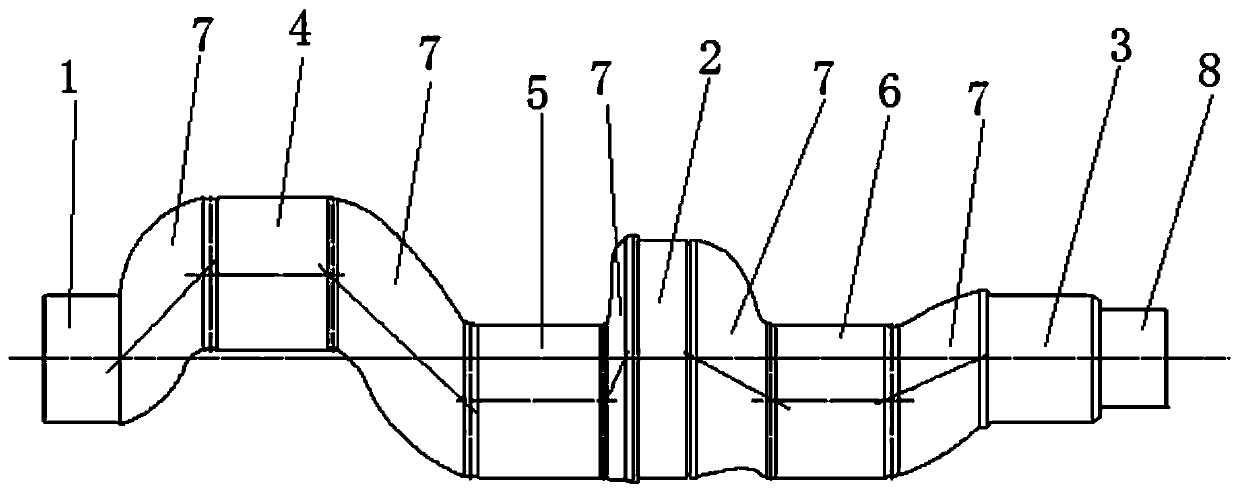

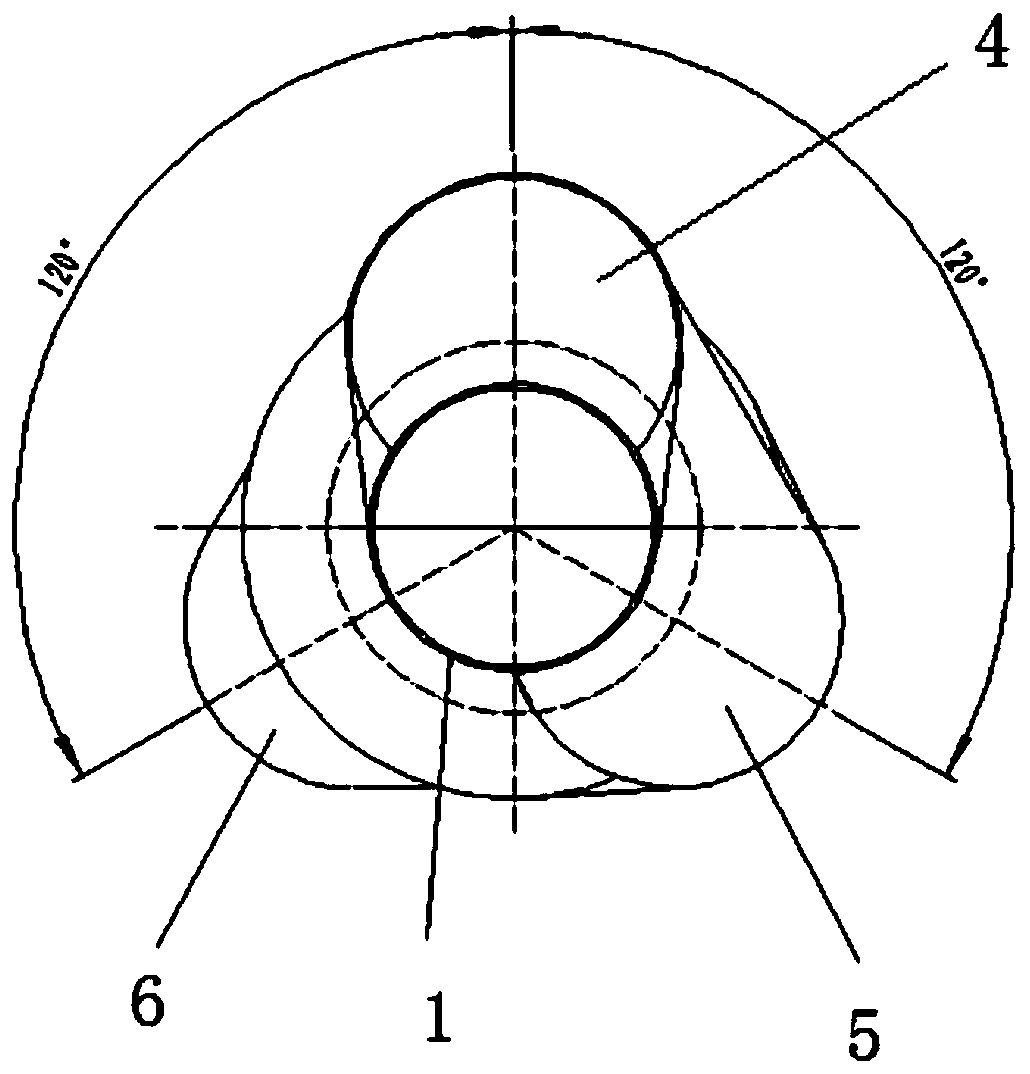

[0042] A three-cylinder three-support crankshaft for a diaphragm pump, the first support journal 1, the first connecting rod journal 4, the second connecting rod journal 5, the second supporting journal 2, the third connecting rod journal 6, the first The diameters of the three supporting journals 3 and the input shaft 8 are 300mm, 360mm, 360mm, 560mm, 360mm, 300mm, and 230mm respectively; since the first connecting rod journal 4 and the second connecting rod journal 5 have equal diameters, the distance is relatively far , it is very likely that there will be stress concentration, insufficient fatigue strength, and fracture. Therefore, the crank arm between the first connecting rod journal 4 and the second connecting rod journal 5 is reasonably designed to improve the stiffness and fatigue of the crank arm. strength.

[0043]The distance between the axes of the first connecting rod journal 4 and the second connecting rod journal 5 is 346mm, and the distance between the adjacen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com