Regeneration method of composite adsorbent for adsorbing electronegative substances

A composite adsorption and electronegativity technology, applied in separation methods, filter regeneration, filtration separation, etc., can solve the problems of cumbersome adsorbent regeneration methods, difficult process control, low adsorption capacity, etc., and achieve excellent regeneration performance and easy control. , the effect of large adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

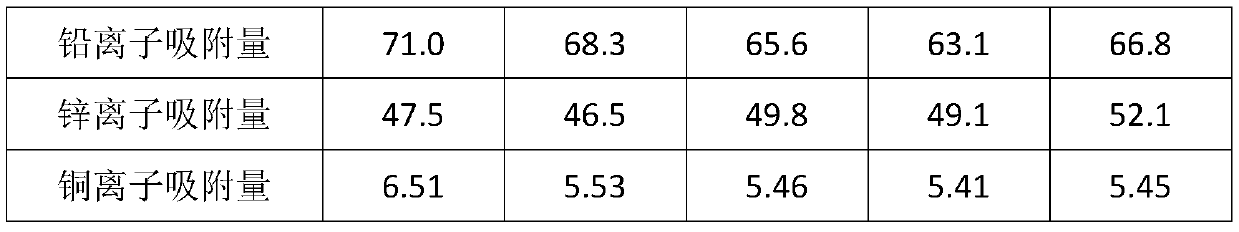

Embodiment 1

[0047] The composite adsorbent material contains conductive polymer polypyrrole, metal oxide titanium dioxide and coupling agent formic acid. The ratio of the three substances is titanium dioxide:polypyrrole:formic acid=10:100:0.1. The specific synthesis steps are as follows: First, at room temperature, add 0.1 part of formic acid to 1000 parts of water and stir to dissolve, then disperse 1.0 part of titanium dioxide in the above solution, stir for 1 hour, then add 100 parts of polypyrrole, stir at room temperature for 8-12 hours, filter, After the obtained solid was washed with a large amount of water, it was dried at 50° C. for 12 hours to obtain a composite adsorbent of titanium dioxide: polypyrrole: formic acid = 10:100:0.1.

Embodiment 2

[0049] The composite adsorbent material contains conductive polymer polypyrrole, metal oxide manganese dioxide and coupling agent oxalic acid. The ratio of the three substances is manganese dioxide:polypyrrole:oxalic acid=50:100:1.0. The specific synthesis steps are as follows: firstly, at room temperature, add 1.0 parts of oxalic acid to 1000 parts of water and stir to dissolve, then disperse 50 parts of manganese dioxide in the above solution, stir for 1 hour, then add 100 parts of polypyrrole, and stir at 30 ° C for 8 After ~12h, filter, the obtained solid was washed with a large amount of water, and then dried at 50°C for 12h to obtain a composite adsorbent of manganese dioxide:polypyrrole:oxalic acid=50:100:1.0.

Embodiment 3

[0051]The composite adsorbent material contains conductive polymer polypyrrole, metal oxide ferric oxide and coupling agent hexanoic acid. The ratio of the three substances is ferric oxide:polypyrrole:hexanoic acid=80:100:2.0. The specific synthesis steps are as follows: First, at room temperature, add 2.0 parts of caproic acid to 1000 parts of water and stir to dissolve, then disperse 80 parts of ferric oxide in the above solution, then add 100 parts of polypyrrole, stir at room temperature for 8-12 hours, filter , the obtained solid was washed with a large amount of water, and dried at 50° C. for 12 hours to obtain a composite adsorbent of ferric oxide: polypyrrole: hexanoic acid = 80:100:2.0.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com