Asphalt concrete composition and preparation method thereof

A technology of asphalt concrete and composition, which is applied in the field of road engineering materials and preparation, to achieve the effect of reducing the average particle size, lower requirements, and improving adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Raw materials: basalt is used for coarse aggregate, limestone is used for fine aggregate; SBS modified asphalt is used for asphalt, natural limestone powder is used for mineral powder, and sintered desulfurization ash is obtained from sintering and desulfurization at Baoshan Base of Baosteel Co., Ltd. Its chemical composition and phase composition are as follows: Shown in Table 1 and Table 2. Refer to the standard "Limits of Radionuclides in Building Materials" (GB 6566-2010) to detect the specific activity of natural radionuclides radium-226, thorium-232, and potassium-40 in sintered desulfurization ash; Toxicity Identification" (GB 5085.3-2007) conducts leaching toxicity tests of copper, zinc, cadmium, lead and other heavy metal elements on sintered desulfurization ash samples. All technical indicators meet the relevant specifications and standards, as shown in Table 3 and Table 4 respectively.

[0027] Table 1 Chemical composition of sintered desulfurization ash

...

Embodiment 2

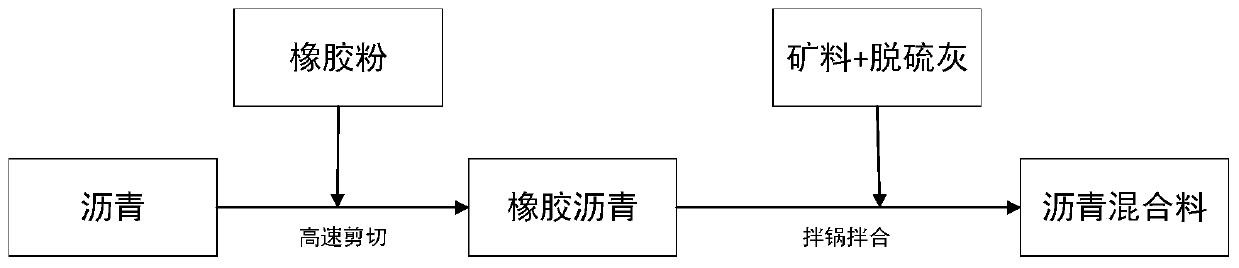

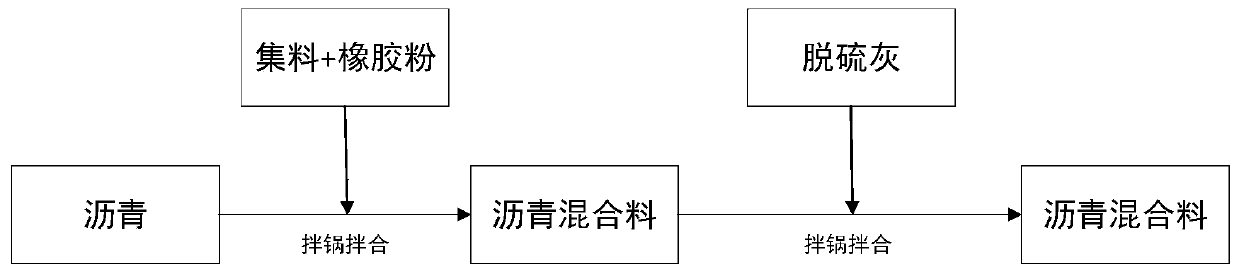

[0055] Raw materials: basalt is used for coarse aggregate, limestone is used for fine aggregate; SBS modified asphalt is used for asphalt, limestone powder is natural limestone powder, and sintering desulfurization ash is obtained from sintering and desulfurization at Baoshan Base of Baosteel Co., Ltd. Standard Specification. The preparation of asphalt concrete and Marshall specimens refers to the relevant test procedures of "Test Regulations for Asphalt and Asphalt Concrete in Highway Engineering" (JTG E20-2011). The specific preparation process is as figure 1 , figure 2 shown. The performance indexes of asphalt concrete obtained by different preparation processes are shown in Table 12.

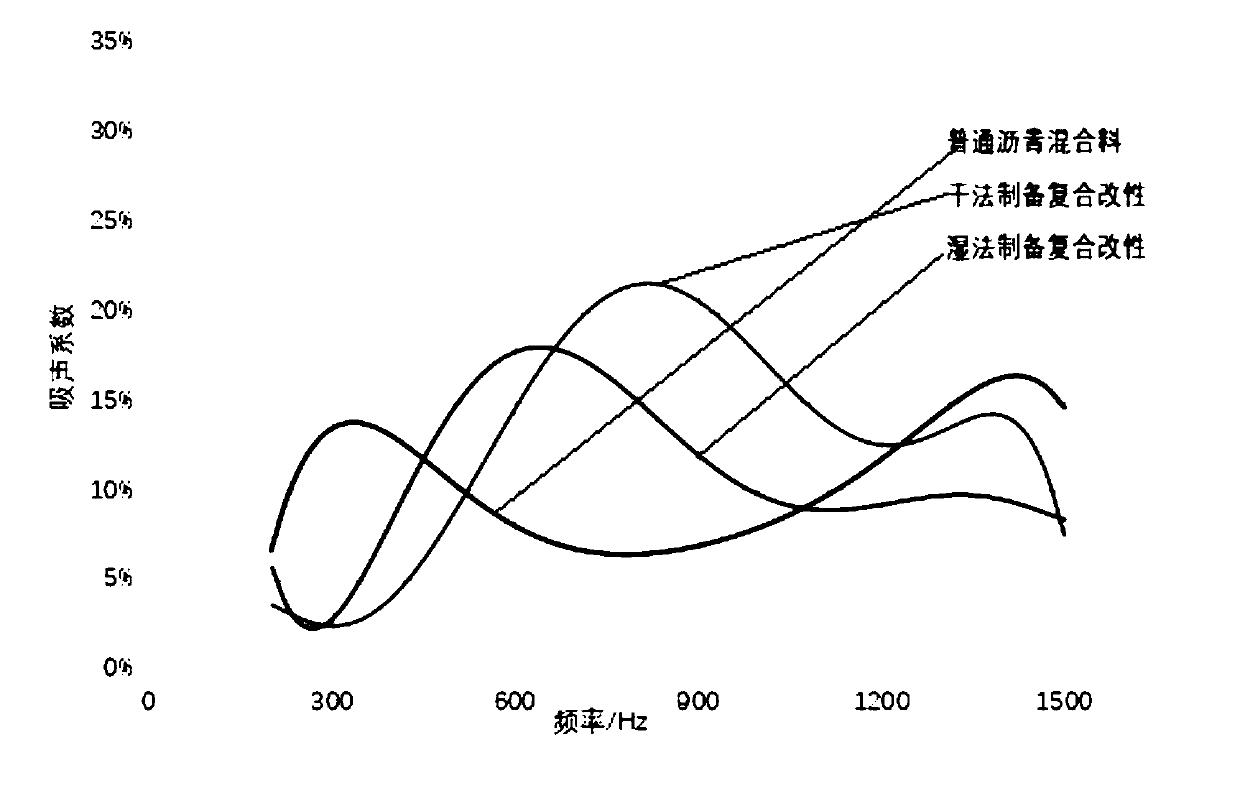

[0056] The impedance tube method is used to measure and study the sound absorption coefficient of ordinary asphalt concrete and dry and wet preparation processes of asphalt concrete modified by sintering desulfurization ash and rubber powder. Rate measurement specification" (GBJ88-85). ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com