Low-temperature cryogenic quick drilling device

A low-temperature cryogenic and fast technology, which is used in drilling equipment, drill bits, earth-moving drilling, etc., can solve the problems of increased drilling costs, no shared drilling costs, and high drilling costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

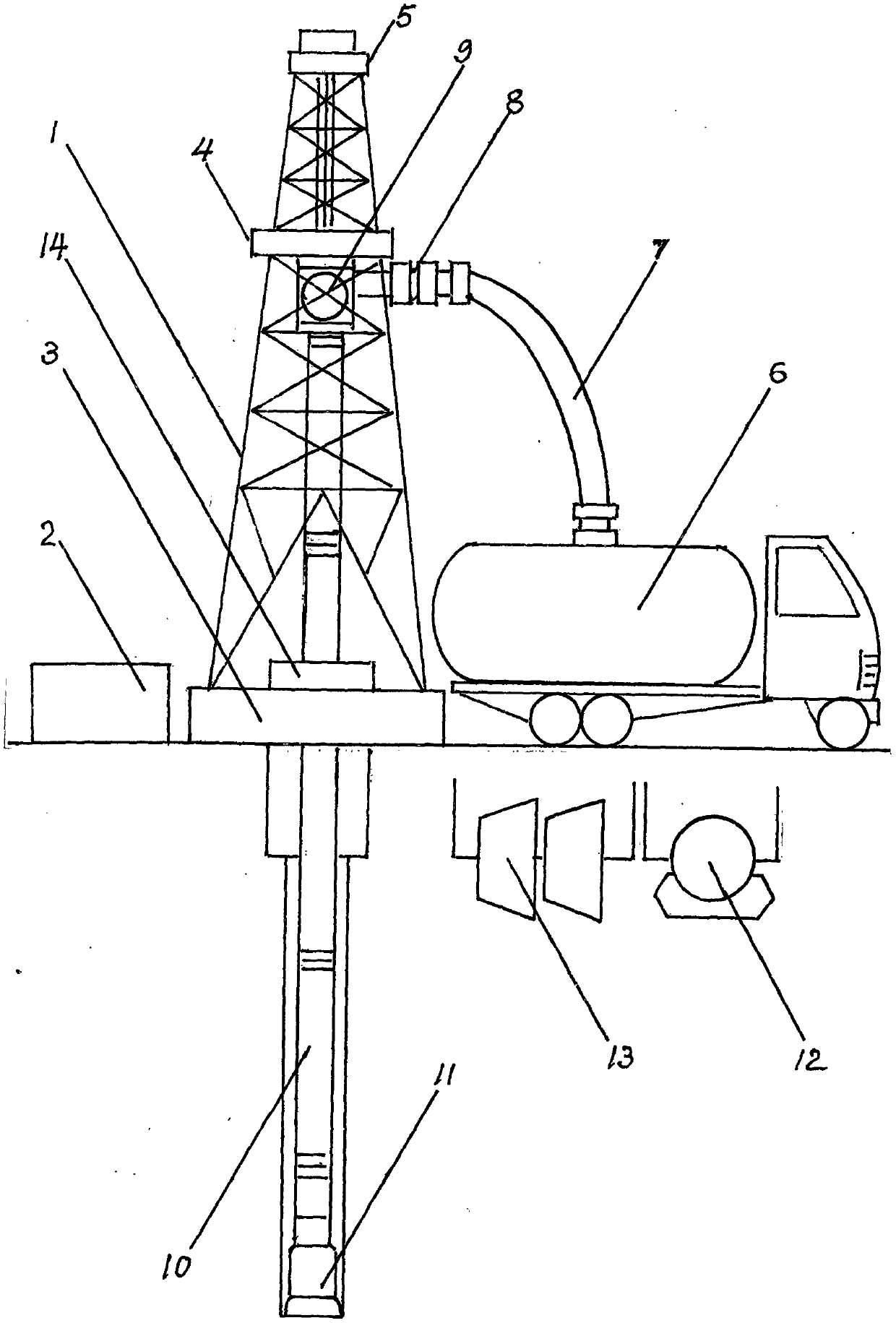

[0025] Embodiment 1, description attached figure 1 . Derrick 1, power 2, turntable 3, traveling block 4, crown block 5, liquid nitrogen tank car 6, liquid nitrogen delivery pipe 7, self-sealing 8, turntable, motor-driven liquid nitrogen rotary conveyor 9, liquid nitrogen delivery drill pipe 10. The low-temperature cryogenic drill bit 11, the liquid nitrogen pump 12, the air compressor 13, and the hydraulic washer 14 are respectively mechanically connected, connected by pipelines, electrically connected, and thermally connected to form a low-temperature cryogenic fast drilling device for rotary drilling. Cutting edge 49 and gage 50 in the low-temperature cryogenic drill bit 11 are manufactured by impregnated diamond technology, and the material is a low-temperature-resistant cryogenic material whose compatibility with the drill bit body 45 is consistent with low expansion rate. The liquid nitrogen control body 46 is made of lightweight low temperature resistant cryogenic resin...

Embodiment 2

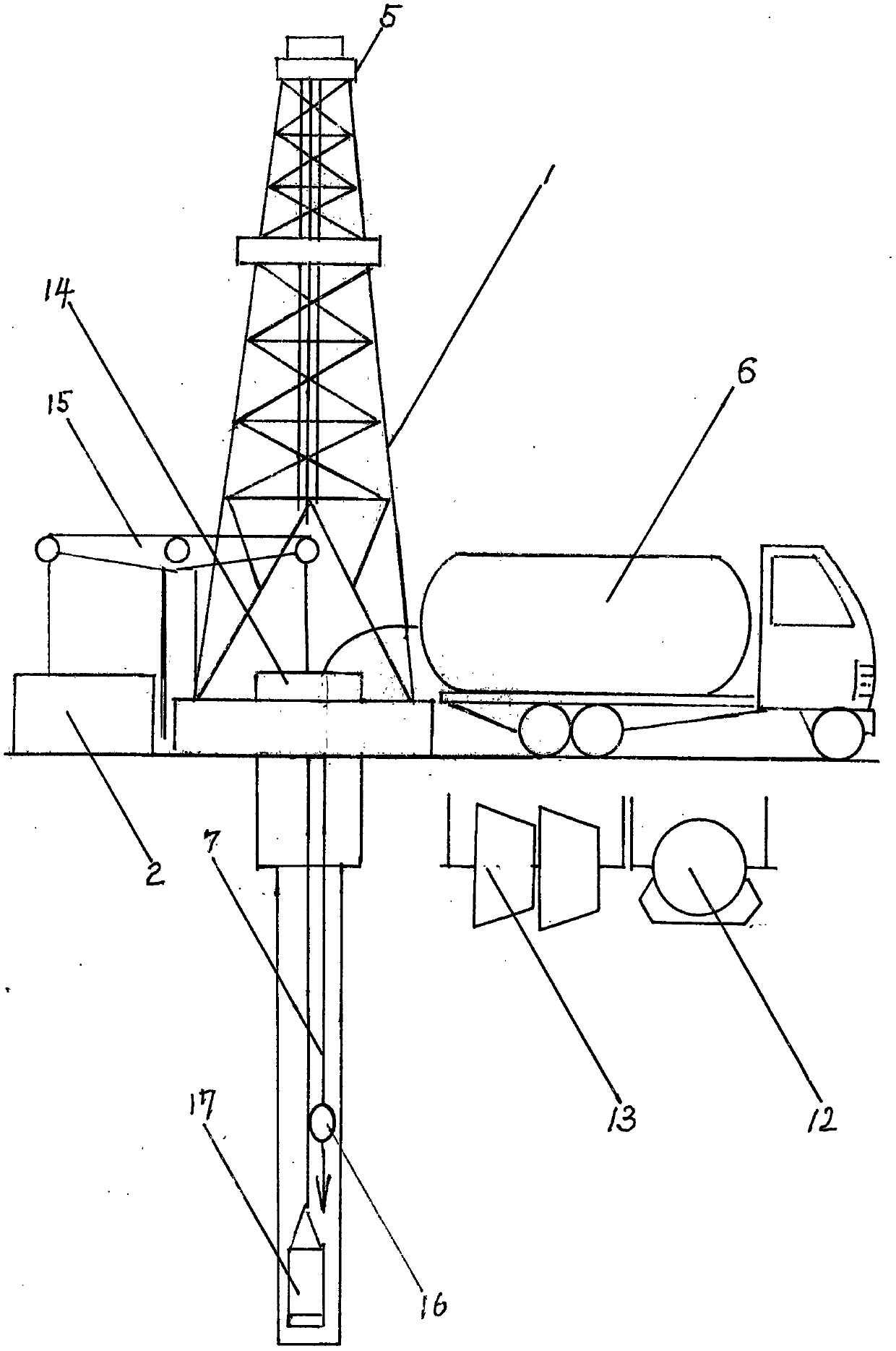

[0027] Embodiment 2, description attached figure 2 . Derrick 1, power 2, crown block 5, beam 15, hydraulic flusher 14, liquid nitrogen tank car 6, liquid nitrogen delivery pipe 7, liquid nitrogen controller 16, ton drill bit 17, liquid nitrogen pump 12, air pressure The machine 13 is connected mechanically, connected by pipelines, connected by electricity, and connected by heat to form a low-temperature cryogenic fast drilling device.

[0028] Embodiment 2 is applicable to the construction of various geotechnical engineering, and is suitable for drilling in hard rock perpendicular to the ground plane or with a small inclination angle. The diameter ranges from 300mm to 2000mm, and the excavation penetration rate is continuously drilled at 3 meters per hour. The material of Dayton drill bit 17 is integral alloy steel. The debris generated in the shallow layer of the drill hole is brought out of the ground by liquid nitrogen gasification, and the residue generated in the deep...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com