Coal-to-oil catalytic extraction technology and special device thereof

A special device, coal-to-oil technology, applied in the petroleum industry, processing hydrocarbon oil, preparation of liquid hydrocarbon mixture, etc., can solve the problems of many auxiliary facilities, high cost of refined oil, large water consumption, etc., to avoid heat intensity Too high, reduce heating intensity, reduce the effect of heating intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

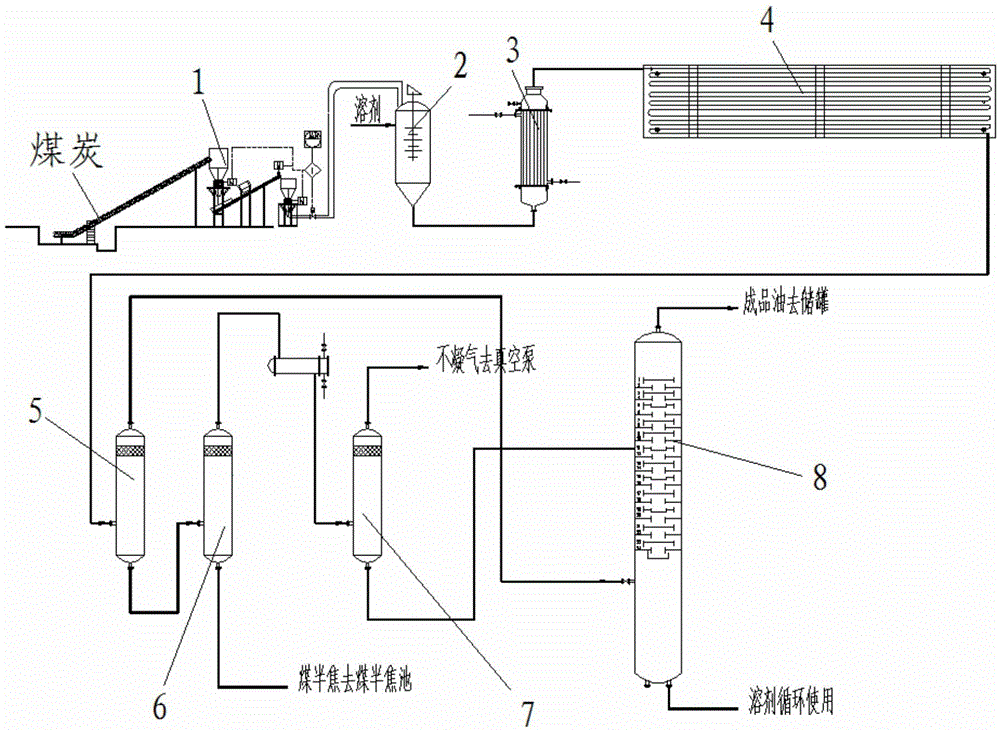

Image

Examples

Embodiment 1

[0063] This embodiment provides a catalytic extraction coal-to-oil process, characterized in that: the catalytic extraction coal-to-oil process, the specific steps are:

[0064] First, pulverize the coal to 180 mesh with a pulverizer. Coal is fully dissolved in the solvent, from solid powder form to coal solution form. The pulverized coal is sent to the pulverized coal tank by means of gas transportation. The pulverized coal enters the pulping tank from the bottom of the pulverized coal tank. The slurry tank is intermittently stirred, so that the pulverized coal and oil are fully mixed into a coal slurry state. The coal slurry enters the tube heater. The outlet temperature of the heater reaches 450°C and the pressure is 5MPA. The coal powder is completely dissolved in the solvent, and the pyrolysis reaction starts to take place. The coal slurry enters the pure axial flow reactor to become a coal solution. The coal solution is kept at 450°C and the pressure is 5MPA. The ...

Embodiment 2

[0075] This embodiment provides a catalytic extraction coal-to-oil process, characterized in that: the catalytic extraction coal-to-oil process, the specific steps are:

[0076] First, pulverize coal to 200 mesh with a pulverizer. Coal is fully dissolved in the solvent, from solid powder form to coal solution form. The pulverized coal is sent to the pulverized coal tank by means of gas transportation. The pulverized coal enters the pulping tank from the bottom of the pulverized coal tank. The slurry tank is intermittently stirred, so that the pulverized coal and oil are fully mixed into a coal slurry state. The coal slurry enters the tube heater. The outlet temperature of the heater reaches 480°C and the pressure is 8MPA. The coal powder is completely dissolved in the solvent, and the pyrolysis reaction starts to take place. The coal slurry enters the pure axial flow reactor to become a coal solution. The coal solution is kept at 480°C and the pressure is 8MPA. The resi...

Embodiment 3

[0087] This embodiment provides a catalytic extraction coal-to-oil process, characterized in that: the catalytic extraction coal-to-oil process, the specific steps are:

[0088] First, pulverize the coal to 220 mesh with a pulverizer. Coal is fully dissolved in the solvent, from solid powder form to coal solution form. The pulverized coal is sent to the pulverized coal tank by means of gas transportation. The pulverized coal enters the pulping tank from the bottom of the pulverized coal tank. The slurry tank is intermittently stirred, so that the pulverized coal and oil are fully mixed into a coal slurry state. The coal slurry enters the tube heater. The outlet temperature of the heater reaches 500°C and the pressure is 10MPA. The coal powder is completely dissolved in the solvent, and the pyrolysis reaction starts to take place. The coal slurry enters the pure axial flow reactor to become a coal solution. The coal solution is kept at 500°C and the pressure is 10MPA. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com