Method for removing organic matters on surface of micro-plastic by optimizing Fenton reagent reaction conditions

A Fenton's reagent and microplastic technology, applied in the field of environmental pollution control, can solve the problems of high price, long digestion time, damage, etc., and achieve the effect of economy, convenience and rapid response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

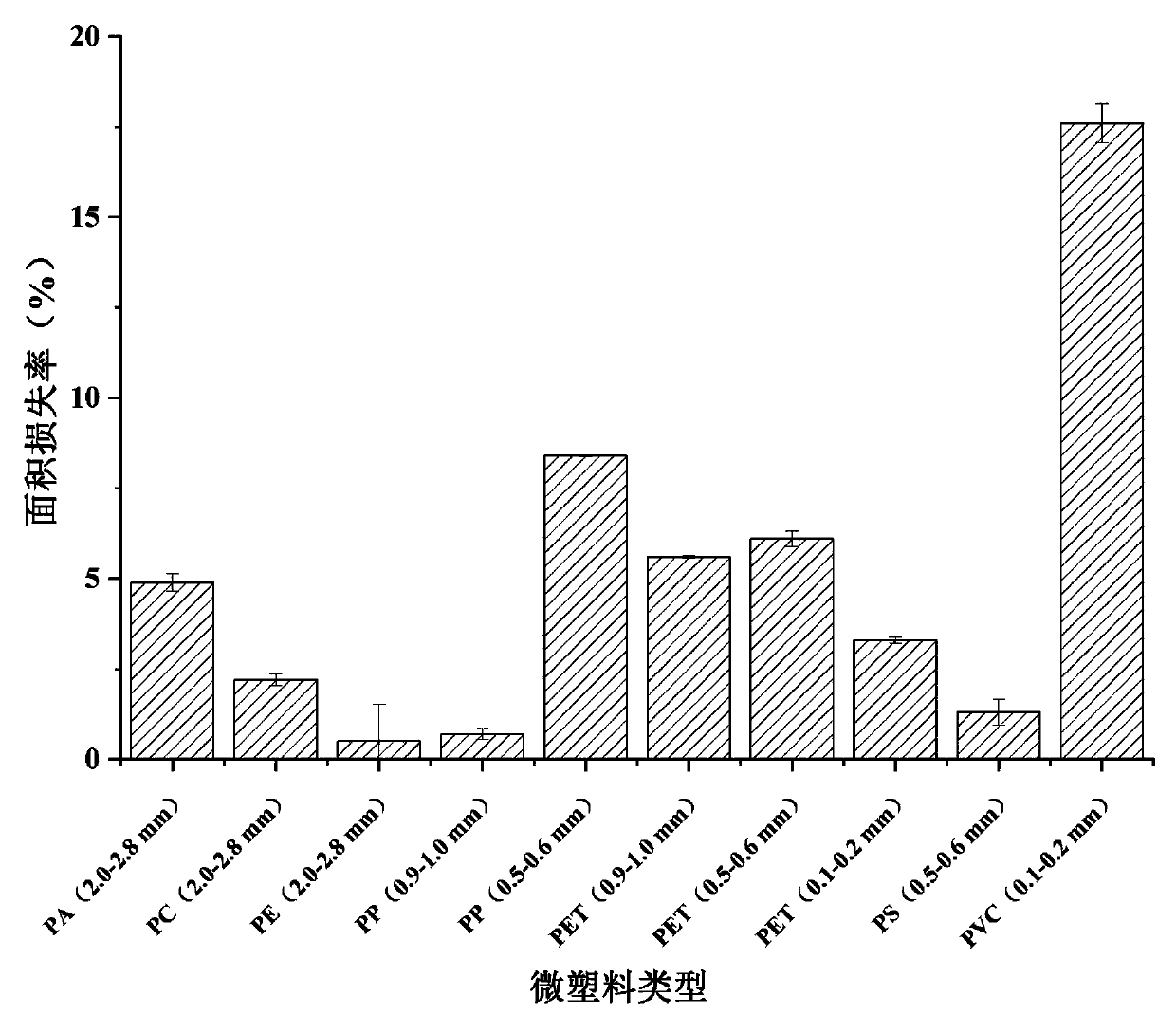

Embodiment 1

[0024] The first step is to prepare Fenton's reagent

[0025] Formulated FeSO 4 ·7H 2 O in water, and an equal volume of 30% H 2 o 2 , to obtain Fenton's reagent; the concentration of the Fenton's reagent is 7.5g / L.

[0026] The second step is to prepare microplastic particles of different sizes

[0027] For microplastics with large size (size ≥0.5mm), such as PA(2.0-2.8mm), PC(2.0-2.8mm), PE(2.0-2.8mm), PP(0.9-1.0mm), PP(0.5- 0.6mm), PET (0.9-1.0mm), PS (0.5-0.6mm) and PET (0.5-0.6mm) are obtained through purchased plastic products; for small-sized microplastics (size ≤ 0.2mm) including PET (0.1 -0.2mm) and PVC (0.1-0.2mm) are obtained by crushing plastics of corresponding large particle size in a pulverizer and sifting through sieves of different meshes.

[0028] The third step is to measure the size of microplastic particles before digestion

[0029] The microplastic particles include large-sized microplastic particles and small-sized microplastic particles.

[0030...

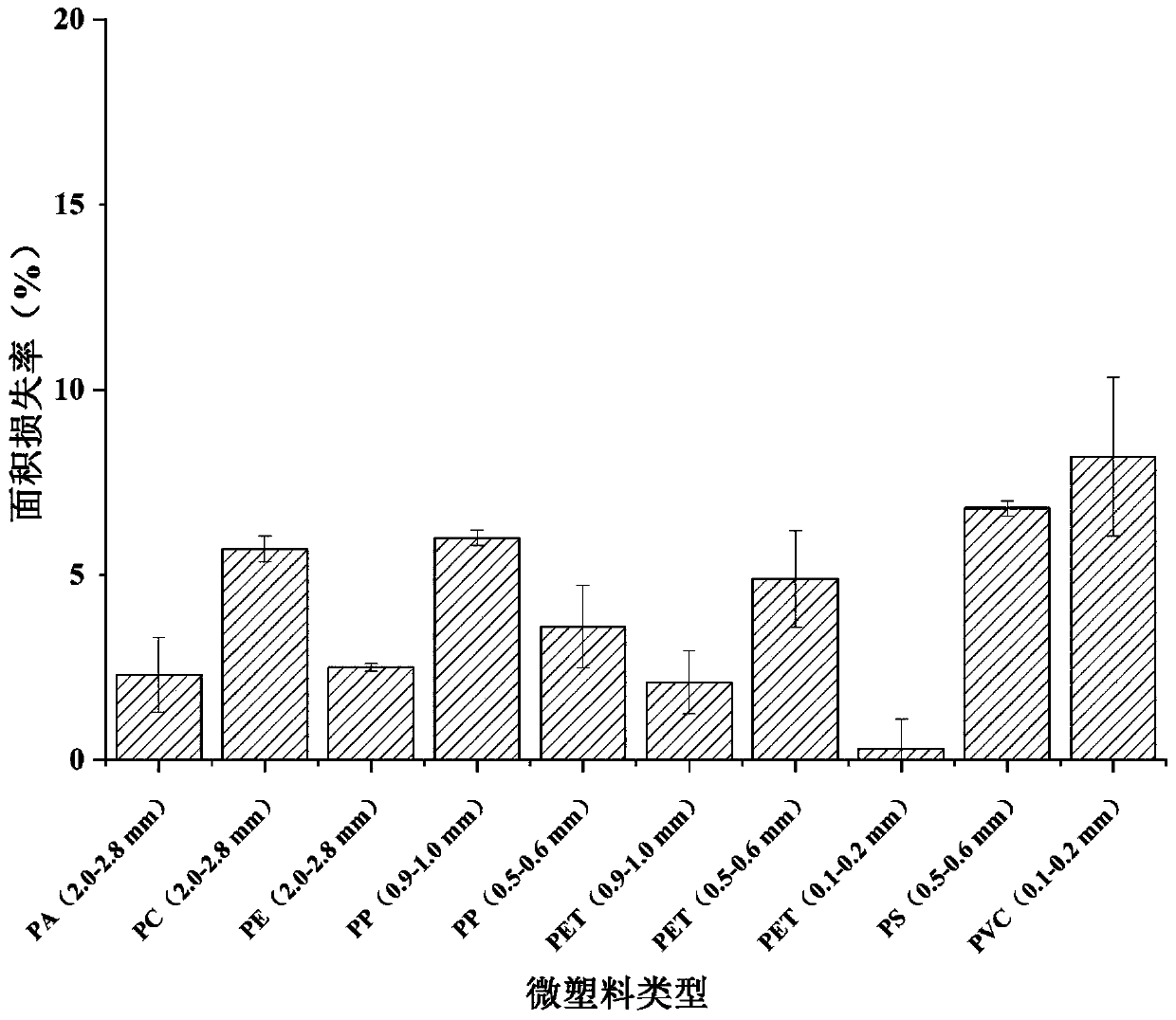

Embodiment 2

[0039] The first step is to prepare Fenton's reagent

[0040] Formulated FeSO 4 ·7H 2 O in water, and an equal volume of 30% H 2 o 2 , to obtain Fenton's reagent; the concentration of the Fenton's reagent is 5g / L.

[0041] The second step is to prepare microplastic particles of different sizes

[0042] For microplastics with large size (size ≥0.5mm), such as PA(2.0-2.8mm), PC(2.0-2.8mm), PE(2.0-2.8mm), PP(0.9-1.0mm), PP(0.5- 0.6mm), PET (0.9-1.0mm), PS (0.5-0.6mm) and PET (0.5-0.6mm) are obtained through purchased plastic products; for small-sized microplastics (size ≤ 0.2mm) including PET (0.1 -0.2mm) and PVC (0.1-0.2mm) are obtained by crushing plastics of corresponding large particle size in a pulverizer and sifting through sieves of different meshes.

[0043] The third step is to measure the size of microplastic particles before digestion

[0044] The microplastic particles include large-sized microplastic particles and small-sized microplastic particles.

[0045] ...

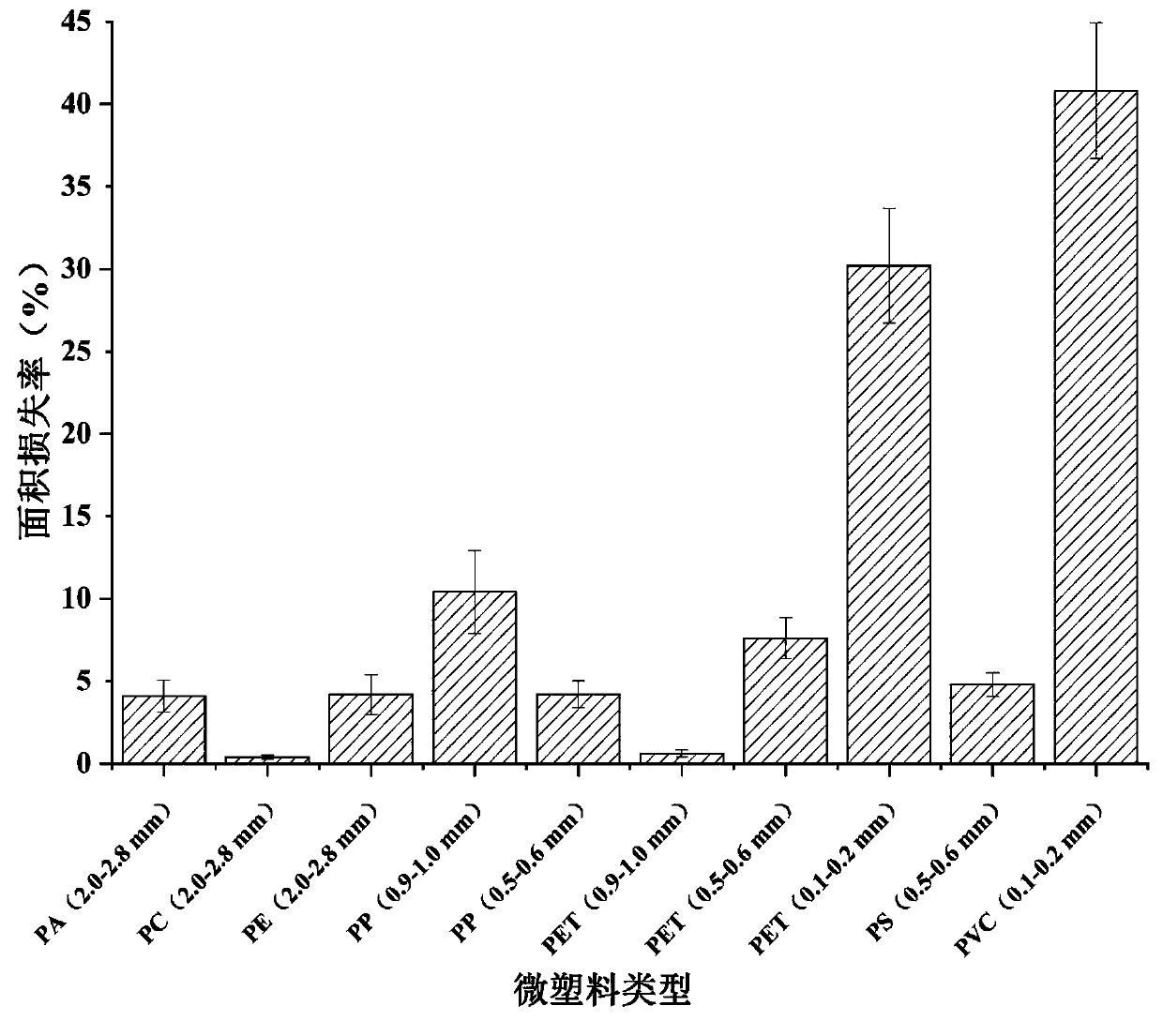

Embodiment 3

[0054] The first step is to prepare Fenton's reagent

[0055] Formulated FeSO 4 ·7H 2 O in water, and an equal volume of 30% H 2 o 2 , to obtain Fenton's reagent; the concentration of the Fenton's reagent is 10g / L.

[0056] The second step is to prepare microplastic particles of different sizes

[0057] For microplastics with large size (size ≥0.5mm), such as PA(2.0-2.8mm), PC(2.0-2.8mm), PE(2.0-2.8mm), PP(0.9-1.0mm), PP(0.5- 0.6mm), PET (0.9-1.0mm), PS (0.5-0.6mm) and PET (0.5-0.6mm) are obtained through purchased plastic products; for small-sized microplastics (size ≤ 0.2mm) including PET (0.1 -0.2mm) and PVC (0.1-0.2mm) are obtained by crushing plastics of corresponding large particle size in a pulverizer and sifting through sieves of different meshes.

[0058] The third step is to measure the size of microplastic particles before digestion

[0059] The microplastic particles include large-sized microplastic particles and small-sized microplastic particles.

[0060]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com