A kind of RFID high-frequency antenna based on transparent flexible substrate and its preparation process

A flexible substrate, high-frequency antenna technology, applied in the direction of antenna, antenna coupling, loop antenna, etc., can solve the problems of difficult to grasp accuracy, difficult operation, long recognition distance, etc., to improve sensitivity performance, reduce mutual coupling interference , the effect of preparation simplification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Below in conjunction with accompanying drawing and specific embodiment, the present invention is further described:

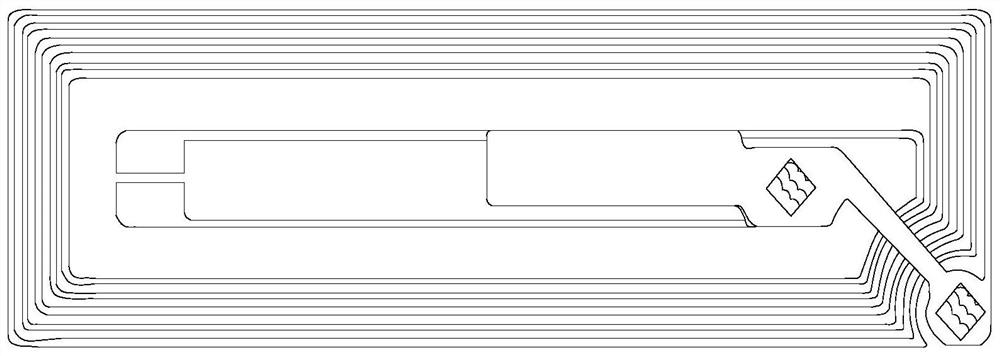

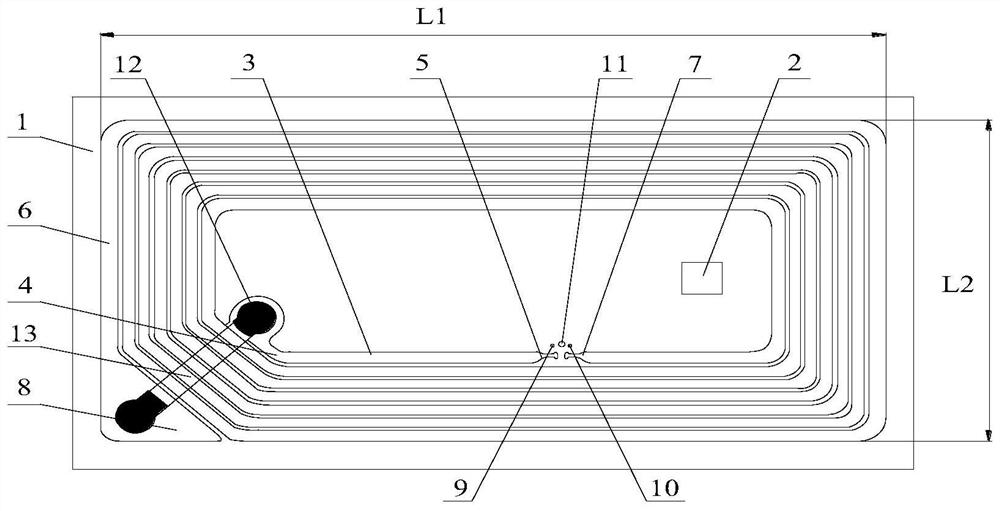

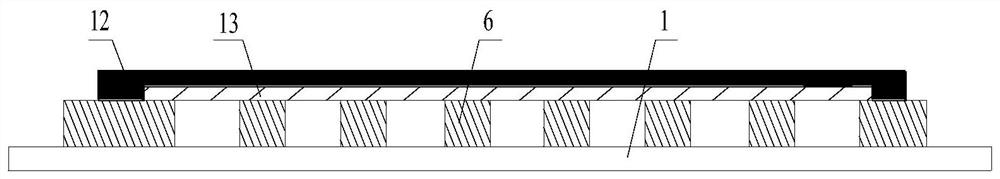

[0027] Such as figure 1 — image 3 Shown, a kind of RFID high-frequency antenna based on transparent flexible substrate, comprises insulating transparent substrate layer 1 and antenna radiation structure, and described antenna radiation structure is arranged on the surface of substrate layer 1, and described antenna radiation structure comprises conductive pattern unit , a circuit connection unit whose two ends are respectively connected to the conductive pattern unit and a positioning arm 2 placed in the conductive pattern unit, the conductive pattern unit includes a first substructure, a second substructure, and an end of the first substructure and a second substructure. The third substructure above the end of the second substructure, the first substructure includes a first rectangular arm 3, one end of the first rectangular arm 3 is provided with a 4...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com