Induction heating system and method for rapid curing of silicon steel self-adhesive coating iron core

A technology of induction heating and rapid curing, applied in the system field, can solve the problem of large temperature difference between the surface and the interior of the heated workpiece, and achieve the effect of improving production efficiency and ensuring curing quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] The induction heating system and method for rapid solidification of the silicon steel self-adhesive coated iron core described in the present invention will be further explained and illustrated in conjunction with the drawings and specific examples of the description below, but this explanation and illustration are not critical to the technology of the present invention. The program constitutes an improper limitation.

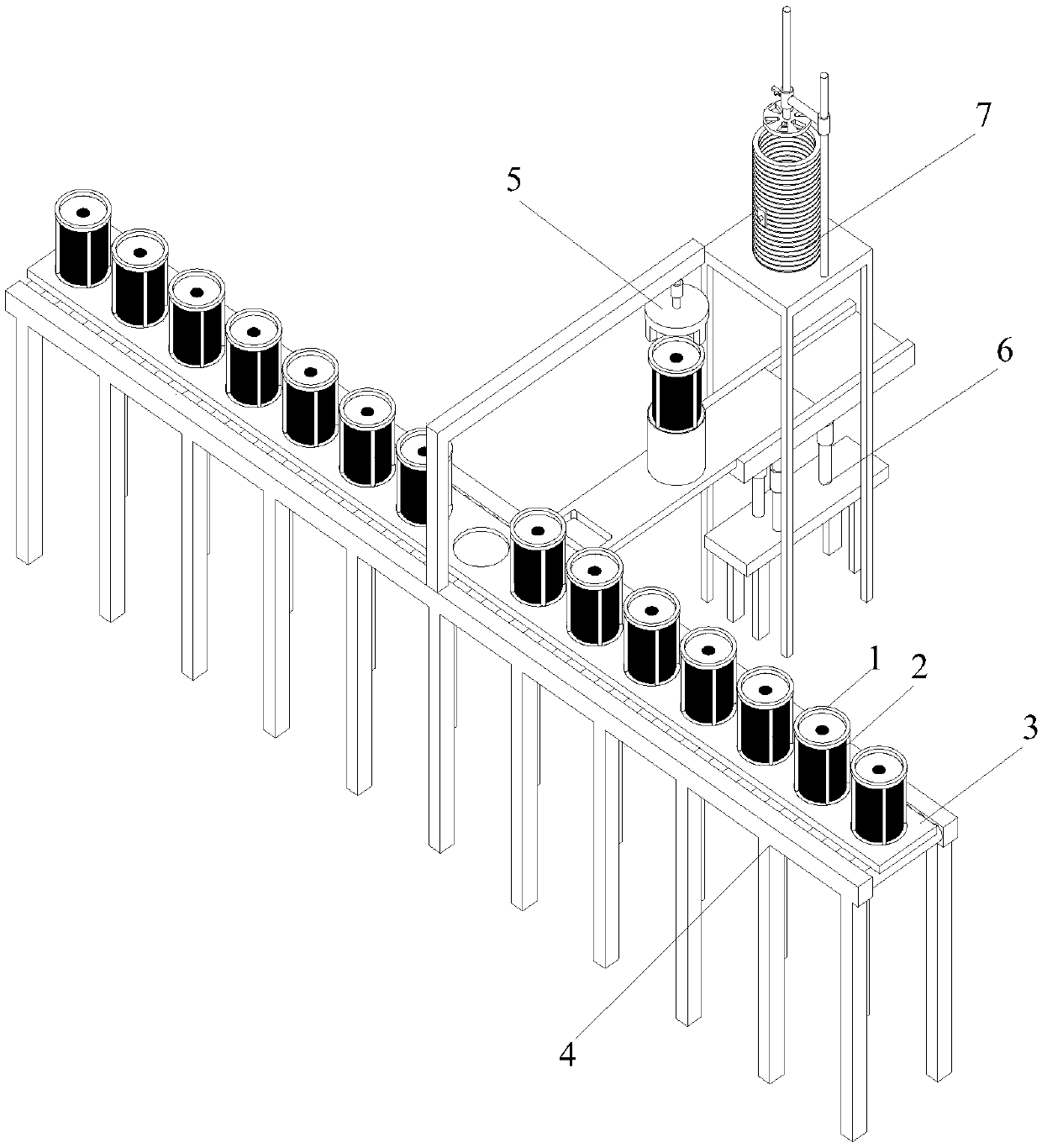

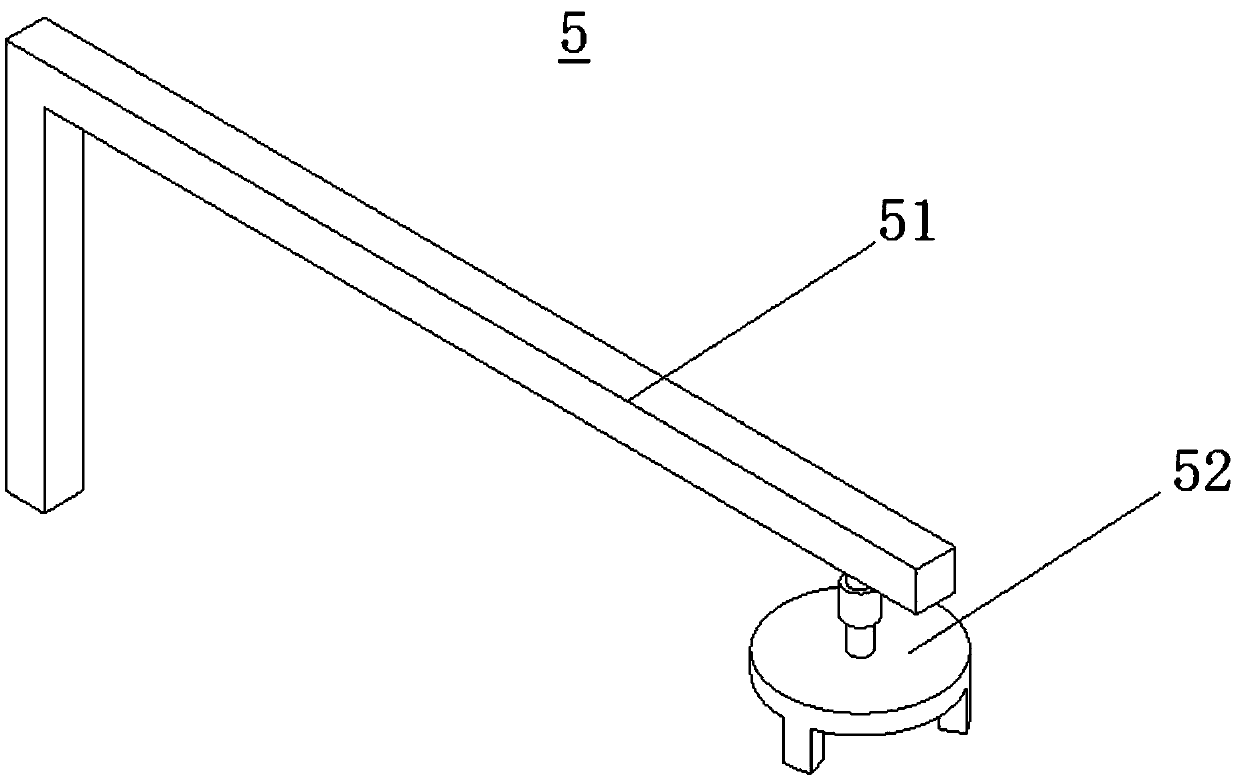

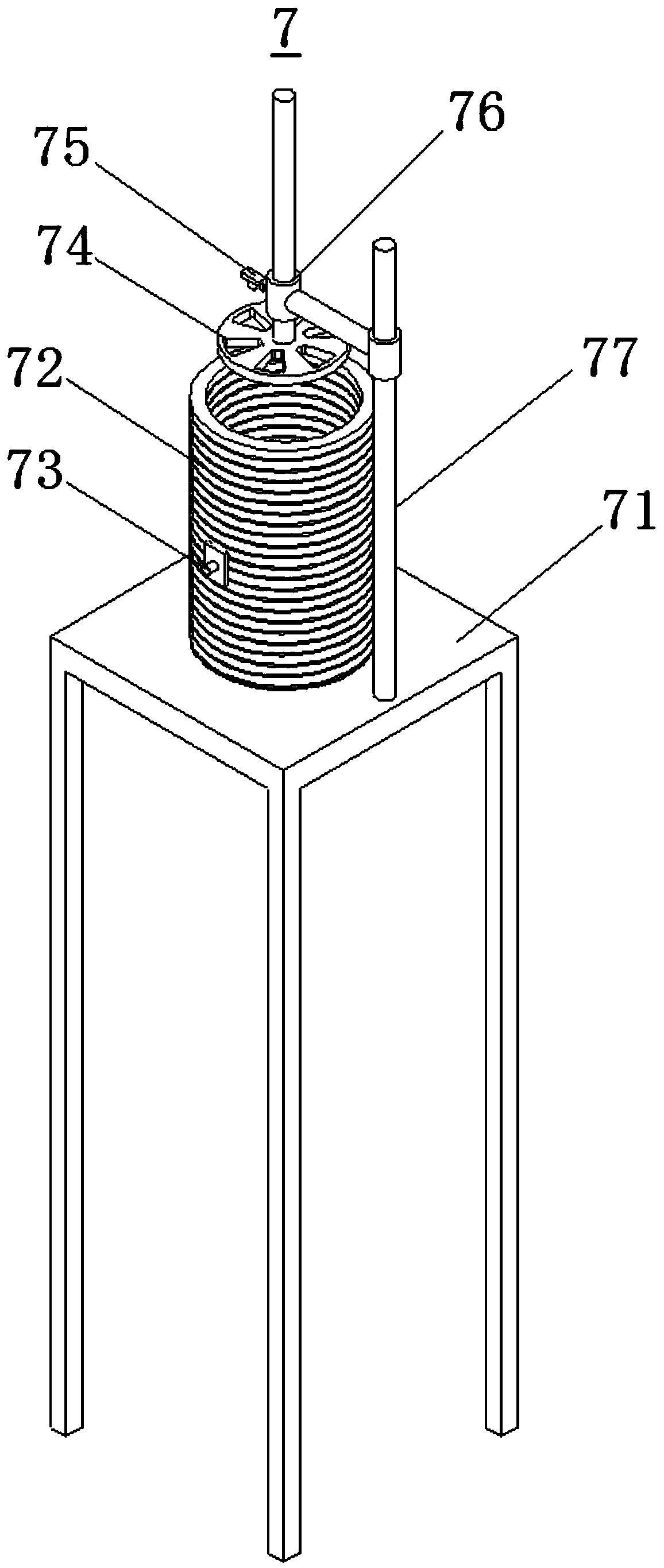

[0055] figure 1 It is a schematic diagram of the structure of the induction heating system for rapid curing of the silicon steel self-adhesive coated iron core described in the present invention in a feeding state in some embodiments. figure 2 It is a structural schematic diagram of some implementations of the feeding and discharging device in the induction heating system for rapid curing of the silicon steel self-adhesive coated iron core according to the present invention. image 3 It is a structural schematic diagram of the induction heating device ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com