Multi-bed rapid cycle kinetic psa

A rapid cycle and kinetic technology, applied in inorganic chemistry, chemical instruments and methods, separation methods, etc., can solve problems such as harmful method productivity and lower overall productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

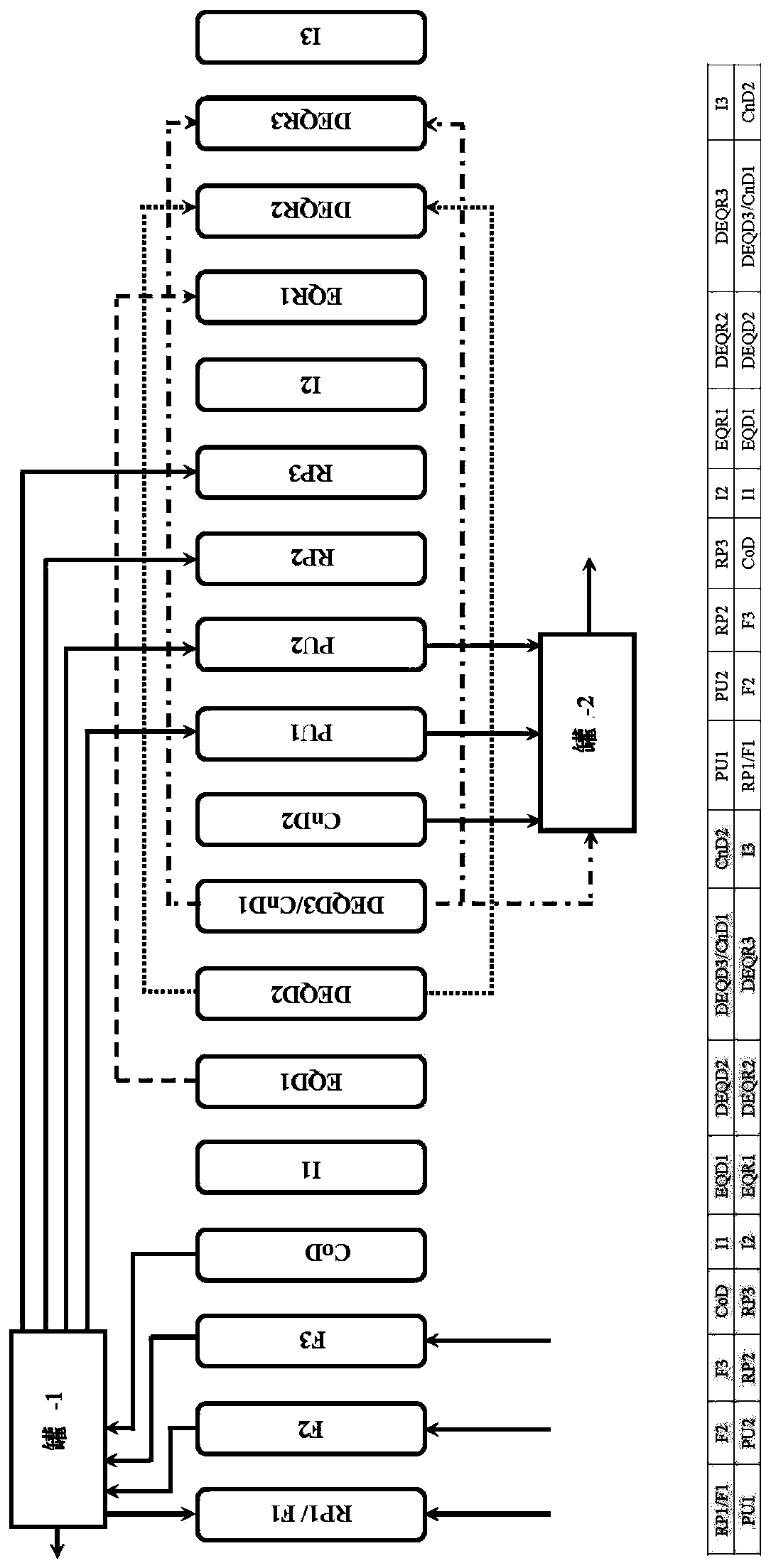

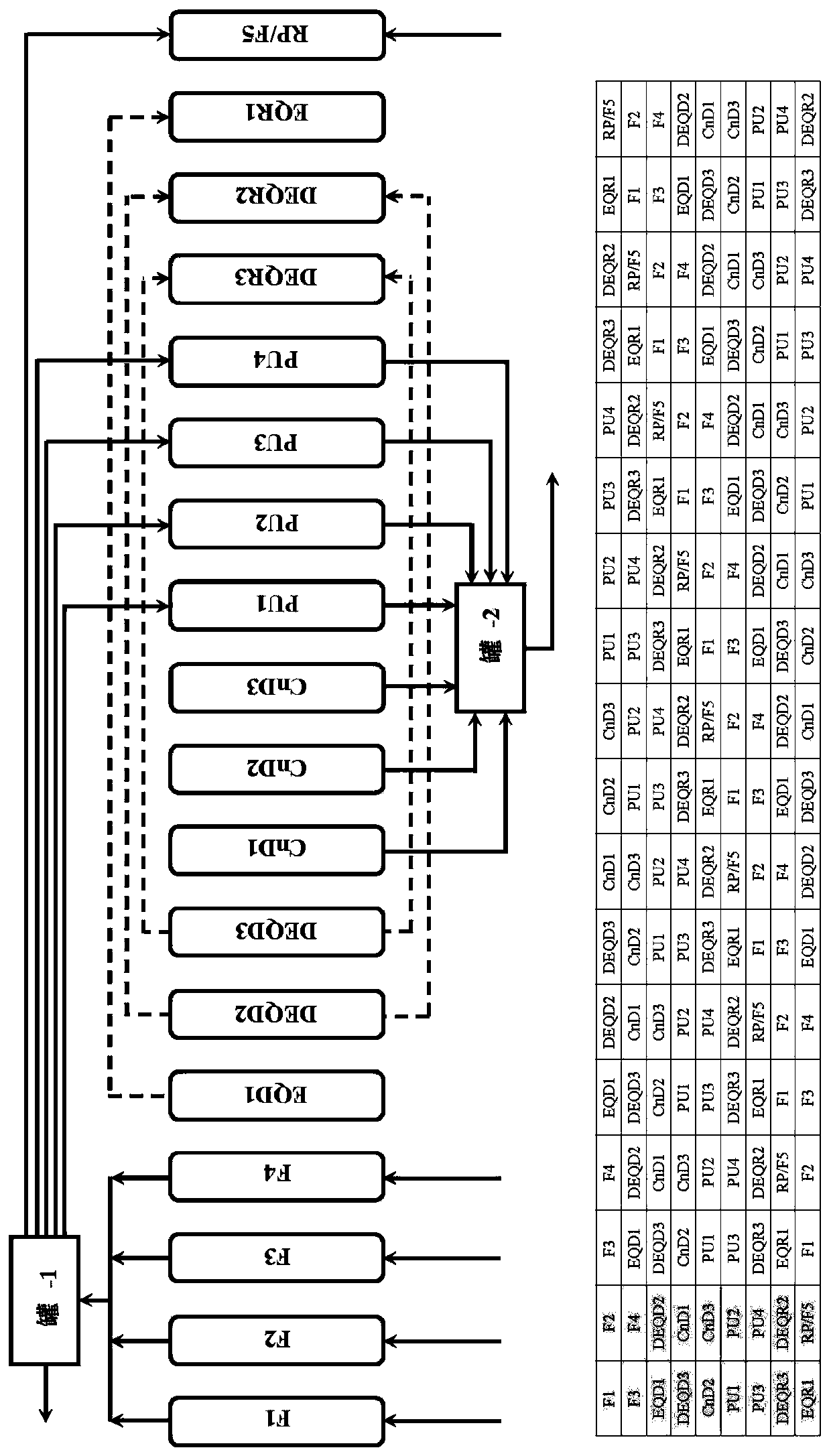

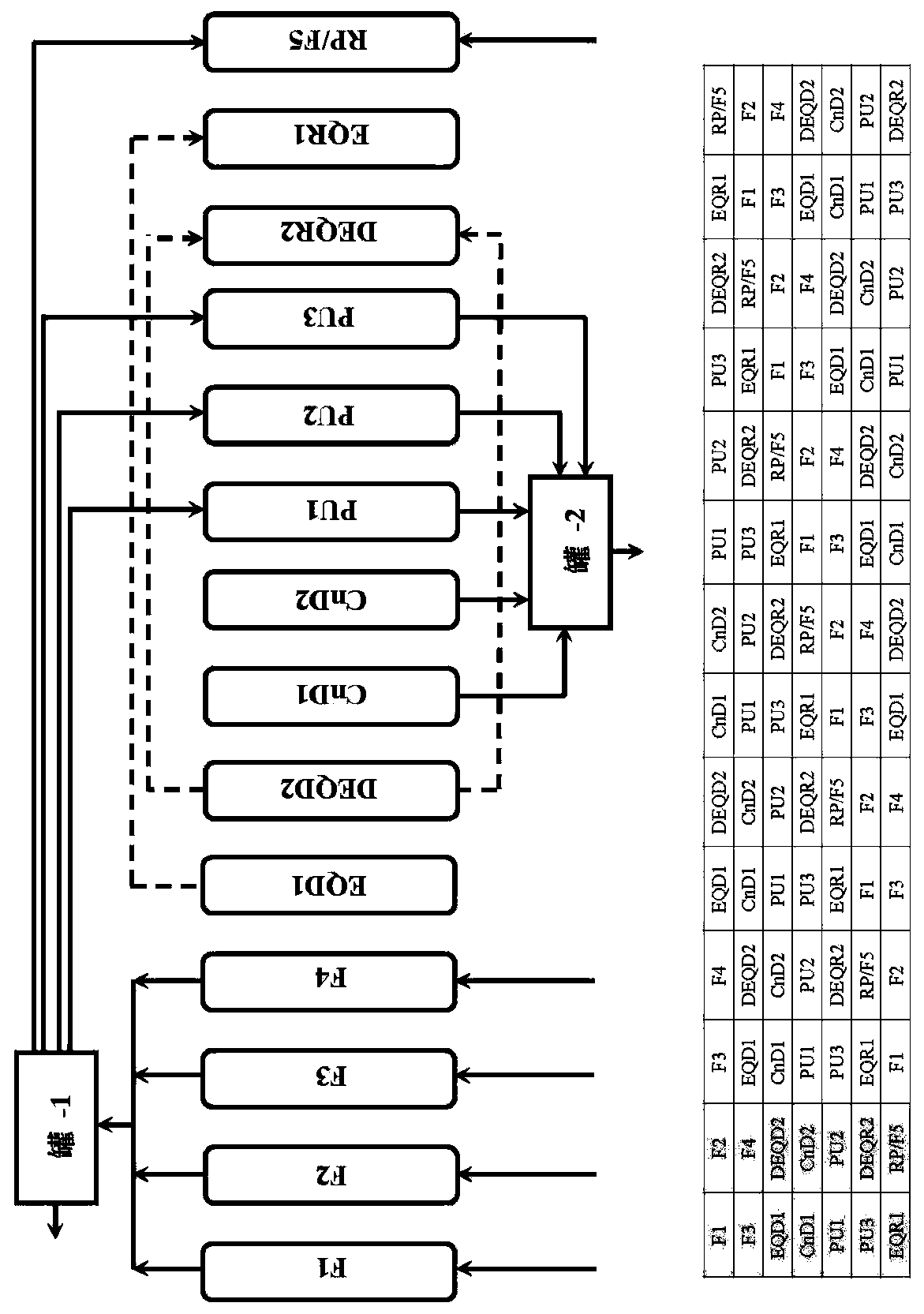

[0172] Using 2-bed multi-step ( figure 1 shown in ) and 9-bed multistep ( figure 2 Shown in ) a pressure swing adsorption (PSA) process cycle to evaluate process performance metrics for feed-to-product ratio and specific productivity using several carbon molecular sieve (CMS) adsorbents for the separation of nitrogen from air. A summary of the oxygen, nitrogen, and argon adsorption rates and the kinetic selectivity of oxygen over nitrogen for each CMS sorbent is presented in Table 1. Note that the kinetic selectivity of oxygen to nitrogen on the 414-01 (“slow”) and 414-02 (“fast”) CMS sorbents is the same, but the rate of oxygen on the 414-02CMS sorbent is slower than that of the 414-01CMS The rate of oxygen on the sorbent is 2 times faster. On the other hand, the 414-02 and 414-03 ("fast") CMS sorbents have the same oxygen rate, but the 414-02 CMS sorbent has a 2x higher kinetic selectivity (oxygen to nitrogen) than the 414-03 sorbent . The bed geometry, operating condit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com