TiO2 photoelectric material having different nano morphologies and prepared by utilizing one-step hydrothermal method, and preparation method and application of TiO2 photoelectric material

A photoelectric material and nano-morphology technology, applied in photovoltaic power generation, circuits, capacitors, etc., can solve the problems of high carrier recombination rate, limited application, large band gap, etc., and achieve cheap and easy-to-obtain raw materials and simple operation steps Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

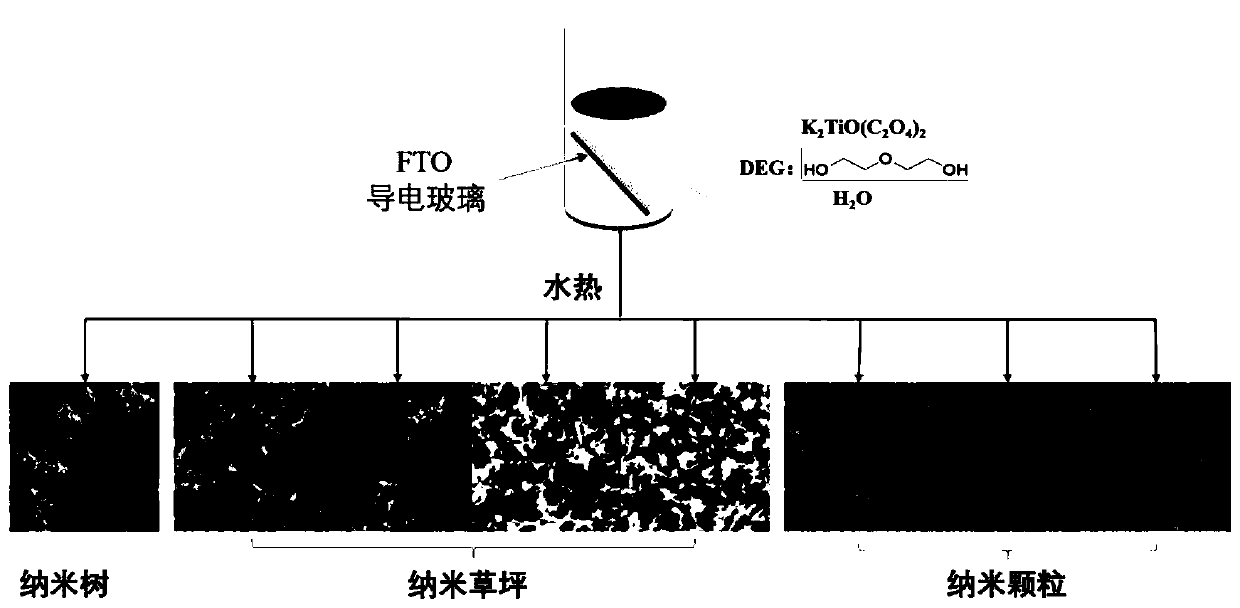

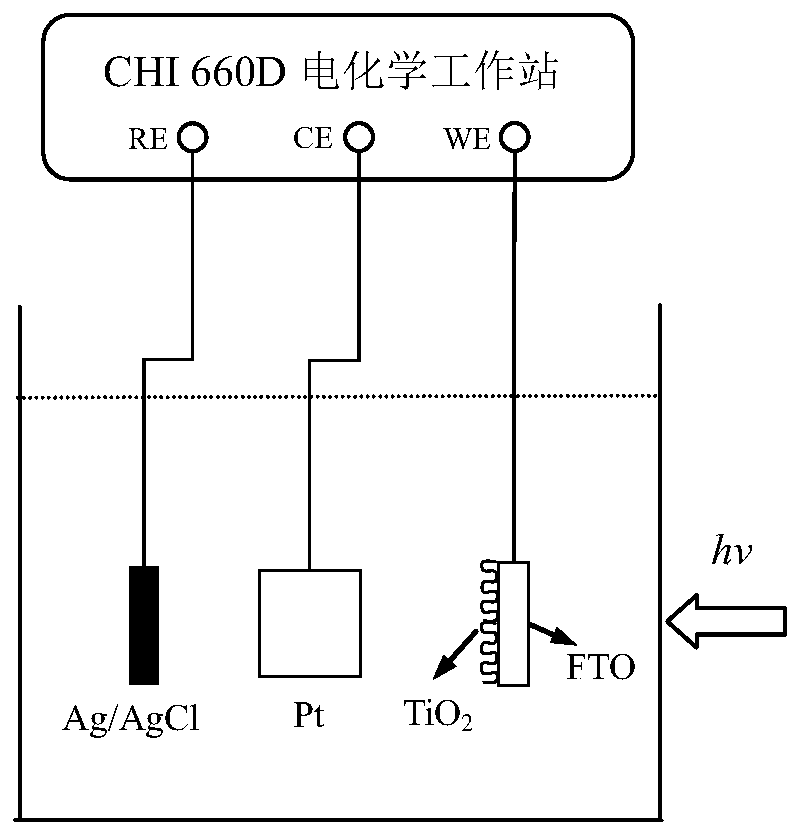

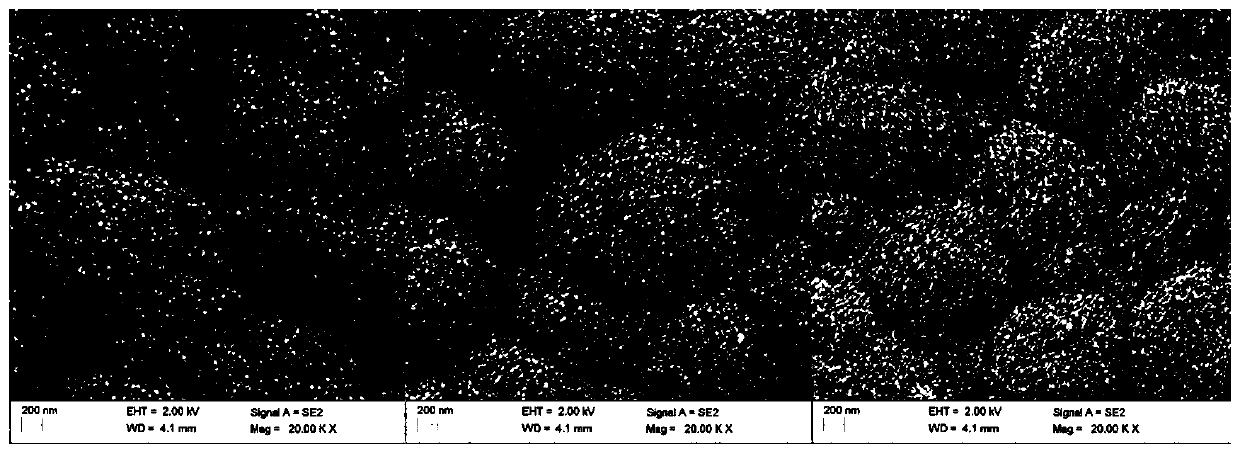

[0035] TiO with nanoparticle morphology for enhanced photoelectrochemical conversion performance 2 Preparation of photoanode:

[0036] 1) Preparation of FTO conductive glass: first cut the FTO glass into 20×10mm 2 size, and then ultrasonically cleaned in analytical grade acetone for 5 minutes, and then cleaned in deionized water for 5 minutes, and then the FTO glass was dried for use.

[0037] 2) Preparation of hydrothermal solution: Add 0.708g of potassium titanium oxalate (PTO) into 30-20mL (preferably 25ml) deionized water, stir for 15 minutes under magnetic stirring, then add 10-20mL (preferably 15ml) a Stirring of diethylene glycol (DEG) was continued for 15 minutes, keeping the total volume of the hydrothermal solution at 40 mL.

[0038] 3) TiO with special nano-morphology 2 Preparation of the photoanode: place the FTO conductive glass in step 1) in the liner of the autoclave, with the conductive side facing down and placed at an angle of 45° to the wall of the autocl...

Embodiment 2

[0046] TiO with nanoturf morphology for enhanced photoelectrochemical conversion performance 2 Preparation of photoanode:

[0047] 1) Preparation of FTO conductive glass: first cut the FTO glass into 20×10mm 2 size, and then ultrasonically cleaned in analytical grade acetone for 5 minutes, and then cleaned in deionized water for 5 minutes, and then the FTO glass was dried for use.

[0048] 2) Preparation of hydrothermal solution: Add 0.708g of potassium titanium oxalate (PTO) into 15-8mL (preferably 10ml) deionized water, stir for 15 minutes under magnetic stirring, then add 25-32mL (preferably 30ml) a Stirring of diethylene glycol (DEG) was continued for 15 minutes, keeping the total volume of the hydrothermal solution at 40 mL.

[0049] 3) TiO with special nano-morphology 2 Preparation of the photoanode: place the FTO conductive glass in step 1) in the liner of the autoclave, with the conductive side facing down and placed at an angle of 45° to the wall of the autoclave. ...

Embodiment 3

[0057] TiO with nanotree morphology for enhanced photoelectrochemical conversion performance 2 Preparation of photoanode:

[0058] 1) Preparation of FTO conductive glass: first cut the FTO glass into 20×10mm2 size, and then ultrasonically cleaned in analytical grade acetone for 5 minutes, and then cleaned in deionized water for 5 minutes, and then the FTO glass was dried for use.

[0059] 2) Preparation of hydrothermal solution: Add 0.708 g of potassium titanium oxalate (PTO) into 5 mL of deionized water, stir for 15 minutes under magnetic stirring, then add 35 mL of diethylene glycol (DEG) and continue stirring for 15 minutes , making the total volume of the hydrothermal solution 40 mL.

[0060] 3) TiO with special nano-morphology 2 Preparation of the photoanode: place the FTO conductive glass in step 1) in the liner of the autoclave, with the conductive side facing down and placed at an angle of 45° to the wall of the autoclave. The solution obtained in step 2) was added ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com