Method for extracting and separating high-viscosity narcissus polysaccharides from narcissus bulbs

A narcissus bulb, high-viscosity technology, applied in the field of natural medicinal chemistry, can solve the problems of high production cost, high freeze-drying cost, starch gelatinization, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

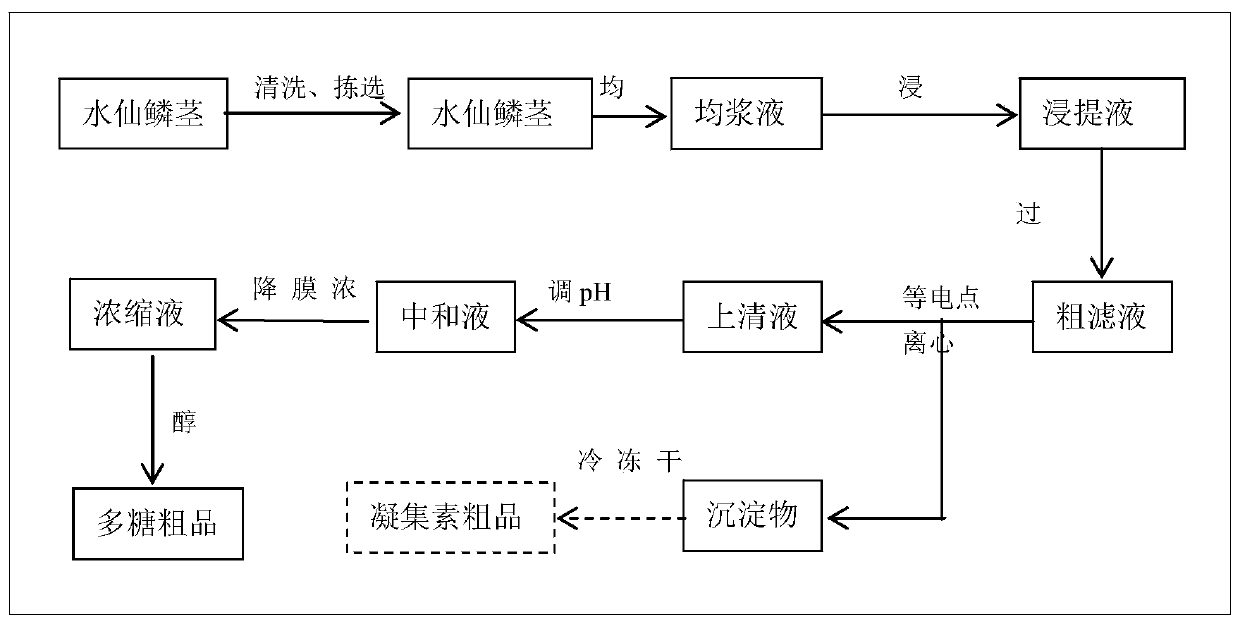

Method used

Image

Examples

Embodiment 1

[0046] Embodiment one: the preparation of narcissus bulb polysaccharide

[0047] (1) Take fresh narcissus bulbs, peel off the outer skin, cut off the root hairs, and rinse with clean water;

[0048] (2) Take 200 g of narcissus bulbs, add 400 mL of 0.05% potassium sorbate+0.1% EDTA aqueous solution, and beat with a homogenizer;

[0049] (3) Add 1600mL aqueous solution containing 0.05% potassium sorbate + 0.1% EDTA to the homogenate, and stir slowly for 30 minutes;

[0050] (4) filter with 200 mesh nylon cloth, collect filtrate;

[0051] (5) Adjust the pH to 3-4 with trichloroacetic acid, and stir at 15r / min for 30min;

[0052] (6) Centrifuge at 2000G for 30min, collect the supernatant;

[0053] (7) Adjust the pH of the supernatant to about 6 with alkali, and then concentrate it to 3-5 ° brix with a rotary evaporator;

[0054] (8) Add 3 times of alcohol to the concentrated solution, stir slowly, let it stand for 60 minutes, filter and collect the precipitate with 100 mesh ny...

Embodiment 2

[0056] Embodiment two: the preparation of narcissus bulb polysaccharide

[0057] (1) Take fresh narcissus bulbs, peel off the outer skin, cut off the root hairs, and rinse with clean water;

[0058] (2) Get 2 kg of narcissus bulbs, shred them, and put them into extraction tanks;

[0059] (3) Add 10kg containing 0.05% potassium sorbate+0.1% EDTA aqueous solution in the extraction tank, and stir for 120min, discharge; Leach again 2 times, each solvent is 5kg;

[0060] (4) Combine the extracts, filter with 200 mesh nylon cloth, and collect the filtrate;

[0061](5) Adjust the pH to 3-4 with trichloroacetic acid, and stir at 30r / min for 30min;

[0062] (6) Centrifuge with a tubular centrifuge to collect the light phase;

[0063] (7) Adjust the pH of the light phase to about 6 with alkali, and then concentrate it to 3-5 ° brix with a falling film evaporator;

[0064] (8) Add 3 times of alcohol to the concentrated solution, stir slowly for 90 minutes, filter and collect the prec...

Embodiment 3

[0066] Embodiment three: the preparation of narcissus bulb polysaccharide

[0067] (1) Take fresh narcissus bulbs, peel off the outer skin, cut off the root hairs, and rinse with clean water;

[0068] (2) get narcissus bulb 100kg, cross extruder, drop into extraction tank;

[0069] (3) Add 1000kg containing 0.05% potassium sorbate+0.1% EDTA aqueous solution to the leaching tank, and stir for 120min, discharge; leaching again 1 time, the solvent is 800kg;

[0070] (4) Combine the extracts, filter with a filter bag of 200 mesh to 400 mesh, and collect the filtrate;

[0071] (5) Adjust the pH to 3-4 with citric acid, and stir at 60r / min for 30min;

[0072] (6) Centrifuge with a tubular centrifuge to collect the light phase;

[0073] (7) Adjust the pH of the light phase to about 6 with alkali, and then concentrate it to 3-5 ° brix with a falling film evaporator;

[0074] (8) Add 2.5 times of alcohol to the concentrated solution, stir slowly for 120 minutes, then filter and col...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com