Environmental-friendly coating, preparation method, application and use method

An environmentally friendly and coating technology, applied in the coating field, can solve the problems of being unable to store for a long time and mass production, etc., and achieve the effect of small limitation, long open time and low film forming temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

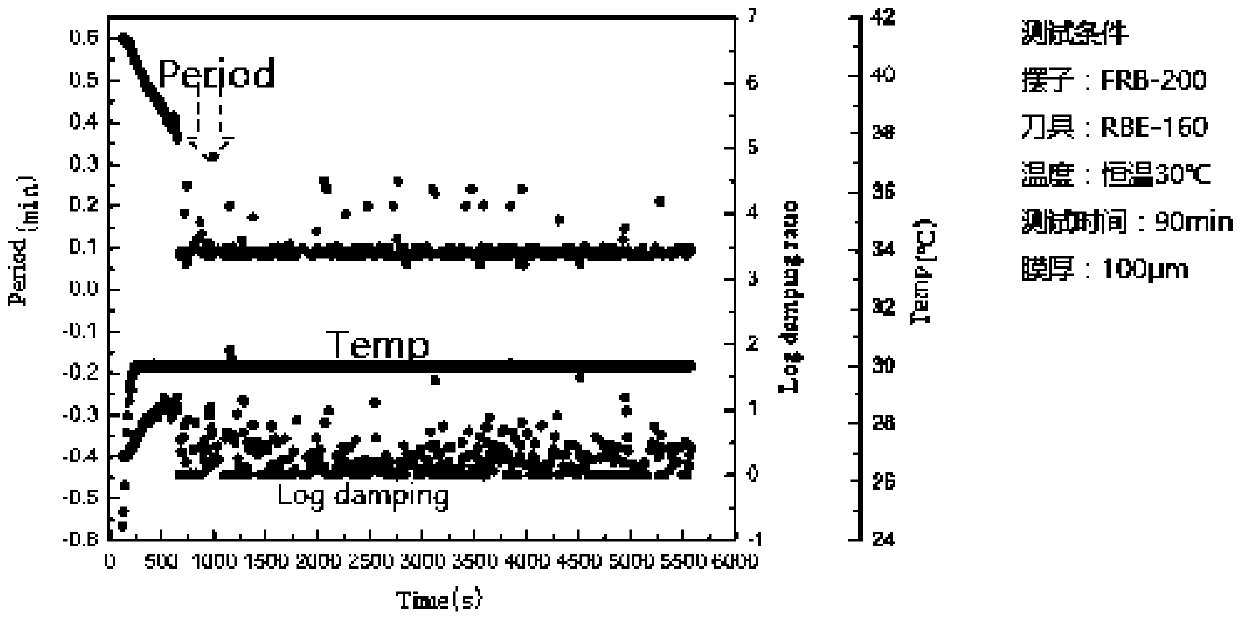

Image

Examples

Embodiment 1

[0074] An environment-friendly paint, comprising liquid component A and reinforcing agent component B packaged independently of each other, in terms of the ratio of parts by mass, the components of the raw materials are composed as follows:

[0075] Liquid Component A consists of:

[0076]

[0077] Enhancer Component B includes:

[0078] 25 parts of lithium silicate and silica sol.

[0079] The mineral oil defoamer is YH-203, the alkali-swellable thickener is alkali-swellable thickener T-900, the viscosity of the liquid component A is 80±5KU, and the pH is 10. The weight ratio of lithium silicate and silica sol is 1:1. The particle size of the solute in the styrene-acrylic emulsion is 0.1-0.2 μm.

[0080] The preparation method of environment-friendly paint, comprises the following steps,

[0081] 1) Preparation of liquid mixture A:

[0082] (1) Take 25 parts by weight of water, add emulsion to it, stir and mix evenly at 600-900 rpm, then add ammonia water, adjust the ...

Embodiment 2

[0091] An environment-friendly paint, comprising liquid component A and reinforcing agent component B packaged independently of each other, in terms of the ratio of parts by mass, the components of the raw materials are composed as follows:

[0092] Liquid Component A consists of:

[0093]

[0094] Enhancer Component B includes:

[0095] 10 parts of lithium silicate and silica sol.

[0096] The liquid component A has a viscosity of 75±5KU and a pH of 8.

[0097] Mineral oil defoamer is YH-203, alkali-swellable thickener is alkali-swellable thickener T-900. The weight ratio of lithium silicate and silica sol is 1:1. The particle size of the solute in the styrene-acrylic emulsion is 0.1-0.2 μm.

[0098] The preparation method of environment-friendly paint, comprises the following steps,

[0099] 1) Preparation of liquid mixture A:

[0100] (1) Take 20 parts by weight of water, add emulsion to it, stir and mix evenly at 600-900 rpm, then add ammonia water, adjust the pH ...

Embodiment 3

[0109] An environment-friendly paint, comprising liquid component A and reinforcing agent component B packaged independently of each other, in terms of the ratio of parts by mass, the components of the raw materials are composed as follows:

[0110] Liquid Component A consists of:

[0111]

[0112]

[0113] Enhancer Component B includes:

[0114] 30 parts of lithium silicate and silica sol.

[0115] The liquid component A has a viscosity of 95±5KU and a pH of 12.

[0116] Mineral oil defoamer is YH-203, alkali-swellable thickener is alkali-swellable thickener T-900. The weight ratio of lithium silicate and silica sol is 1:1. The particle size of the solute in the styrene-acrylic emulsion is 0.1-0.2 μm.

[0117] The preparation method of environment-friendly paint, comprises the following steps,

[0118] 1) Preparation of liquid mixture A:

[0119] (1) Take 30 parts by weight of water, add emulsion to it, stir and mix evenly at 600-900 rpm, then add ammonia water, adj...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com