Color-accurately-controllable composite fiber

A composite fiber and color technology, which is applied in the field of textile fibers, can solve the problems that it is difficult to ensure that there will be no weighing errors in raw materials between batches, the color of composite fibers cannot be accurately controlled, and the color cannot be precisely controlled. Fiber chromaticity consistency, raw material saving, and the effect of precise control of fiber color chromaticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

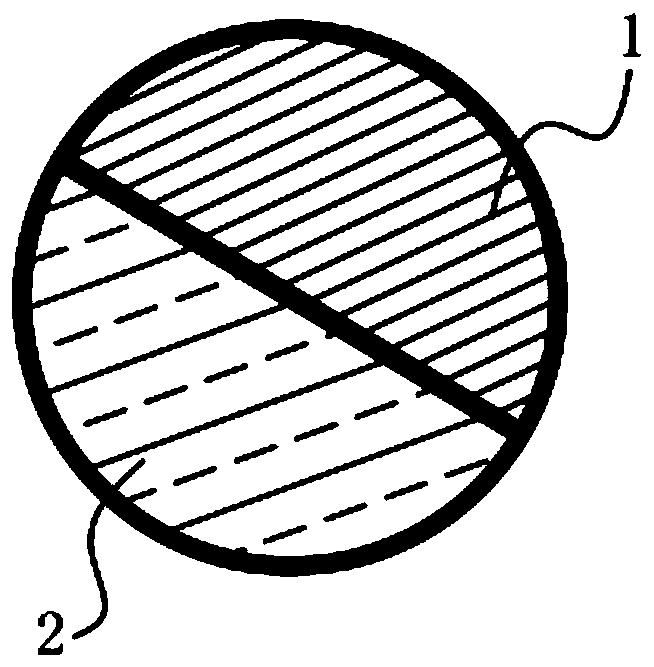

[0023] Such as figure 1 As shown, a composite fiber with precise and controllable color. The composite fiber is firstly selected the dyeing masterbatch of the corresponding color according to the required color, and then the dyeing masterbatch and high polymer are mixed and melted to form a spinning dope melt, and then the spinning The silk stock solution melt is extruded from the spinneret assembly to prepare the required composite fiber, and the cross section of the composite fiber is a multi-component structure. If you want to prepare orange composite fiber, first prepare red dyeing masterbatch and yellow dyeing masterbatch, then mix and melt red dyeing masterbatch and polyester to form red spinning dope melt, and mix yellow dyeing masterbatch and polyester The yellow spinning dope melt was formed by melting, and then the red spinning dope melt and the yellow spinning dope melt were simultaneously extruded from the pie-shaped spinneret to prepare orange composite fibers.

...

Embodiment 2

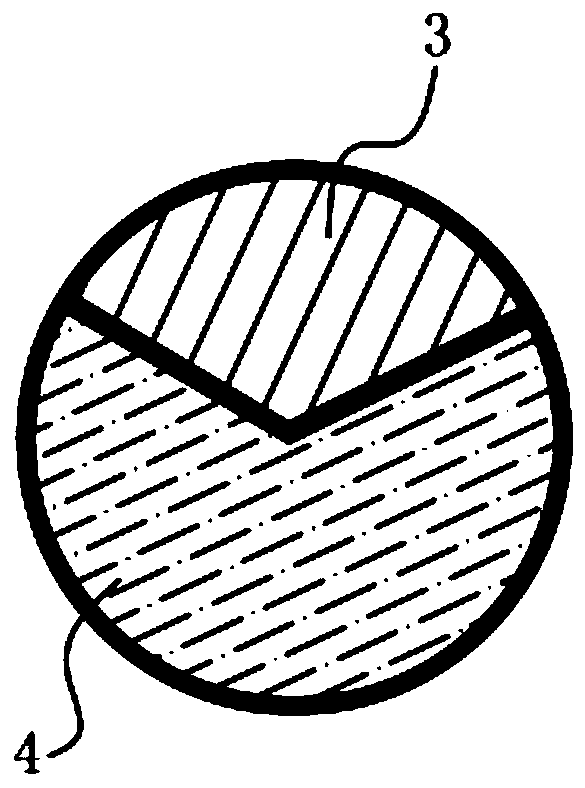

[0026] Such as figure 2 As shown, the difference from Example 1 is that the polymer materials and area ratios of the two color orange segments in the composite fiber are different. Specifically, the composite fiber is first mixed and melted with red masterbatch and polyester to form a red spinning dope melt, mixing and melting yellow masterbatch and PA to form a yellow spinning dope melt, and then simultaneously melting the red spinning dope melt and the yellow spinning dope melt were extruded from the segmented-pie spinneret to obtain the desired composite fiber. The area ratio of red orange petal 3 and yellow orange petal 4 in the composite fiber cross section is 1:2, the prepared composite fiber is dark orange, and the ratio of red masterbatch and yellow masterbatch required when preparing positive orange composite fiber is 1:2.

Embodiment 3

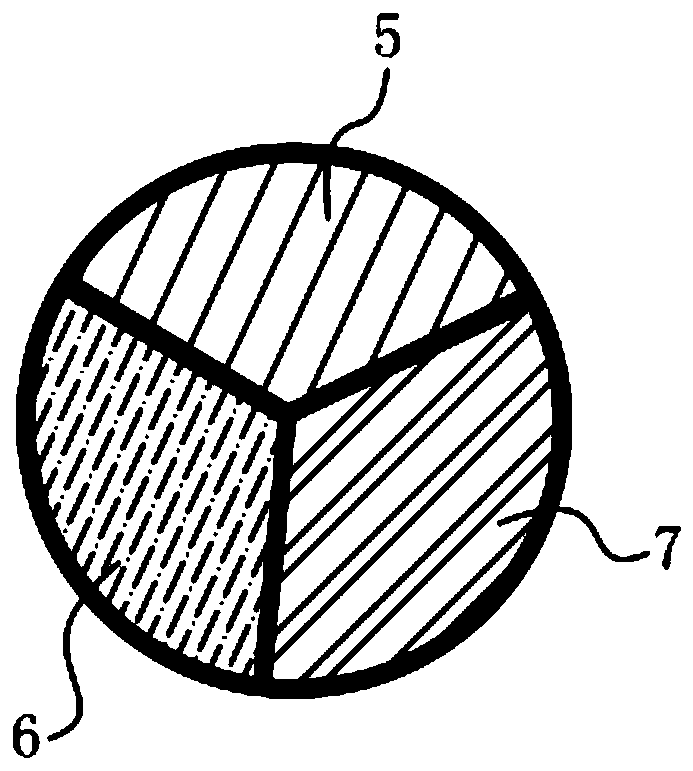

[0028] Such as image 3 As shown, the difference from Examples 1 and 2 is that the number of segments in the composite fiber, the polymer material, and the area ratio are different. Specifically, the composite fiber is first mixed and melted with red masterbatch and COPA to form a red spinning dope melt, mixed and melted with yellow masterbatch and COPA to form a yellow spinning dope melt, and mixed and melted with white masterbatch and COPA to form a white spinning dope melt. Spinning the dope melt, and then extruding the red spinning dope melt, the yellow spinning dope melt and the white spinning dope melt from the pie-shaped spinneret at the same time to prepare the required composite fiber.

[0029]The cross-section of the composite fiber is orange-segment-shaped, and the number of orange-segments is 3, that is, red orange-segmented, yellow-orange-segmented and white-segmented-orange-segmented. In the cross-section of the composite fiber, red orange-segmented 5 and yellow-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com