A bionic-based three-dimensional spider web laminated tube heat exchanger

A tubular heat exchanger and spider web technology, applied in indirect heat exchangers, heat exchanger types, tubular elements, etc., can solve the problems of large mass, inconvenient installation, and difficulty in further improving heat exchange capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

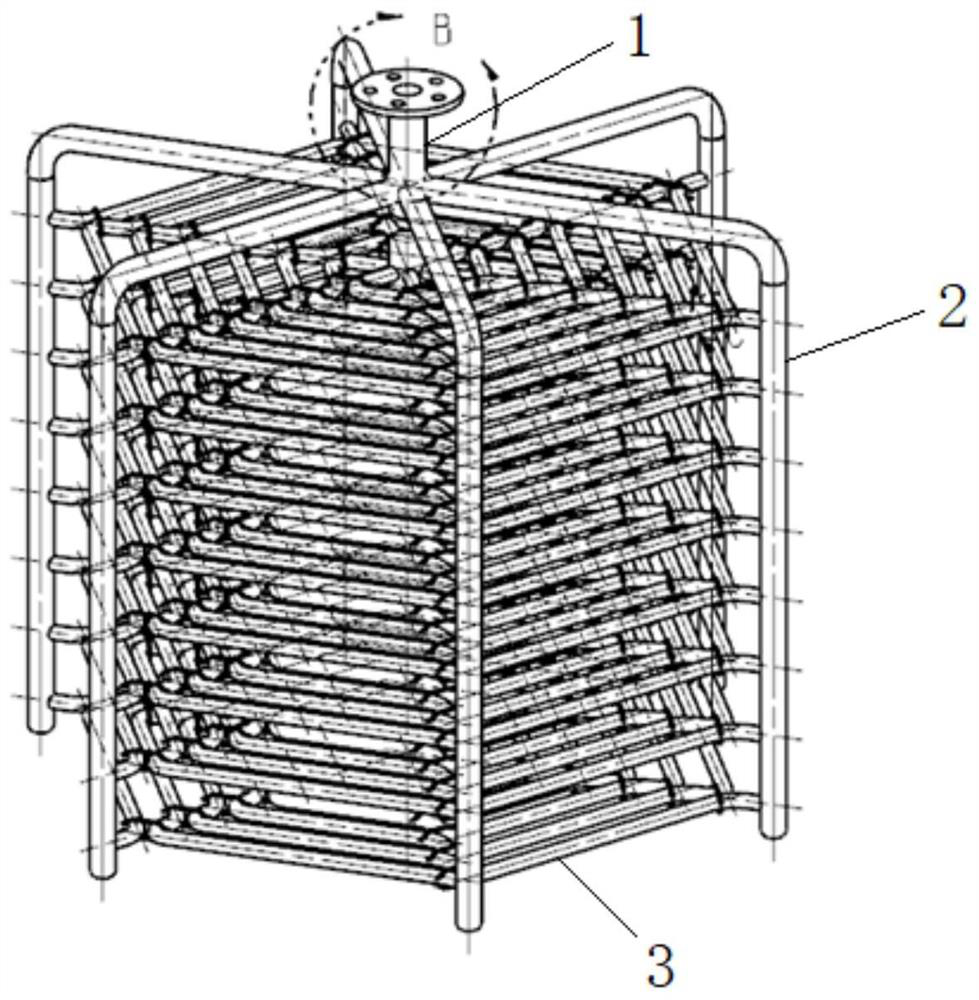

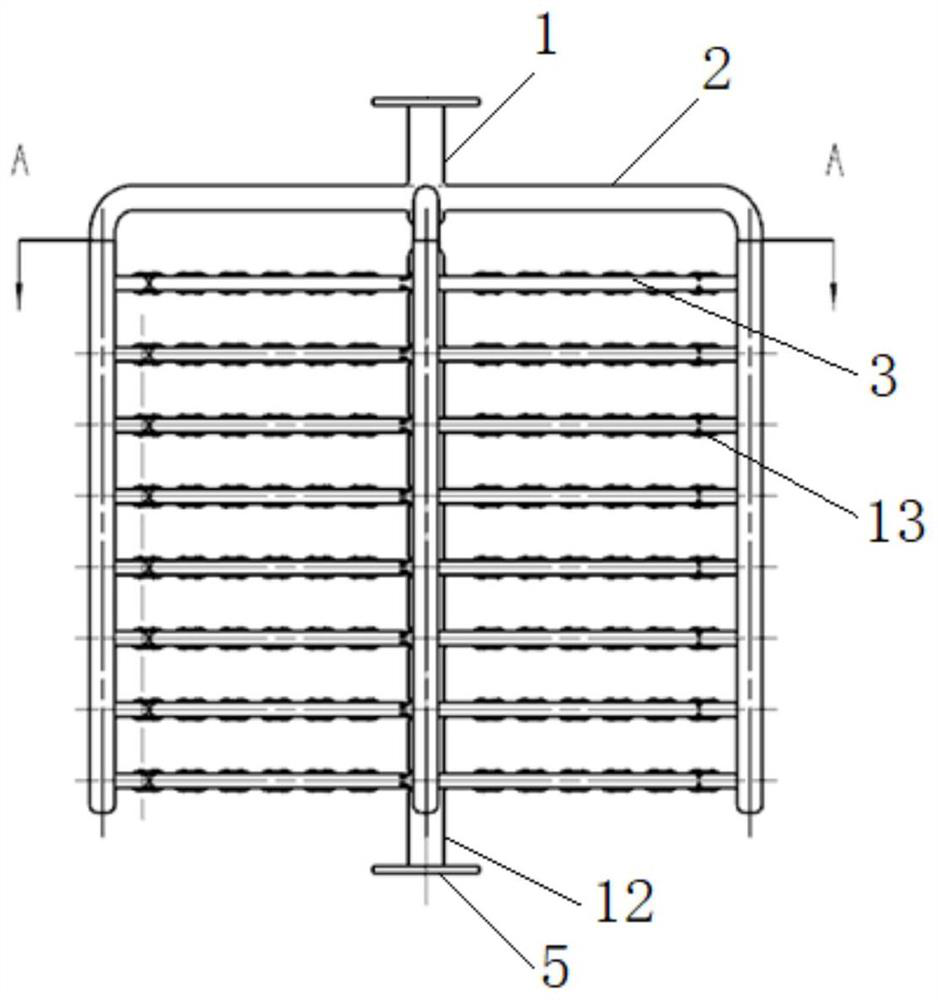

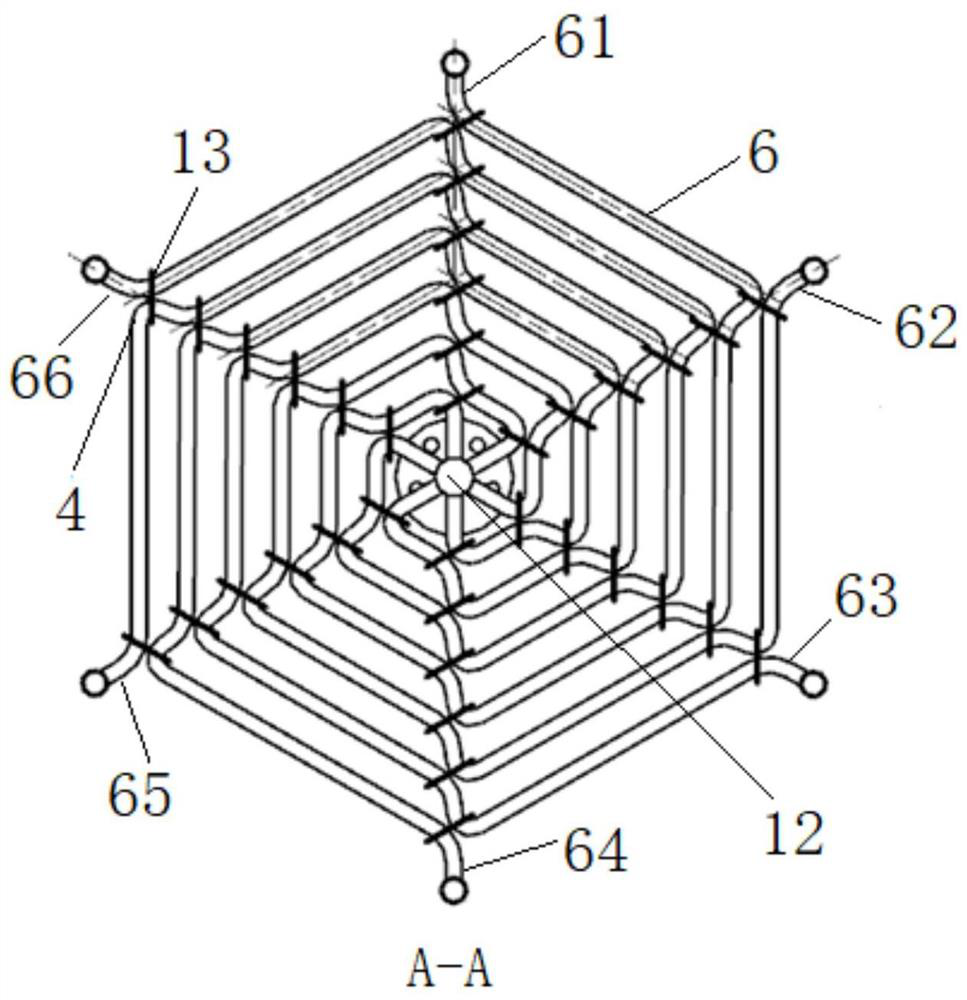

[0038] The embodiment of the present invention is based on the structure of the bionic three-dimensional spider web laminated tube heat exchanger, such as Figure 1-5 As shown, it includes a multi-layer regular hexagonal net-type pipeline 3, and the net-type pipeline 3 includes six bent tubes 6 with the same structure, specifically the first bent tube 61, the second bent tube 62, and the third bent tube. Bending tube 63, the 4th bending tube 64, the 5th bending tube 65, the 6th bending tube 66, each bending tube 6 gradually surrounds from the outermost side of the regular hexagon to the center of the regular hexagon, and in the regular hexagon The radius of the circumscribed circle of the polygon is bent toward the center to form a bent section 4, and the bent sections 4 of two adjacent bent tubes 6 are fixed together by flexible buckles 13, and the outer ends of all bent tubes 6 pass through corresponding The distribution pipeline 2 communicates with the inlet 1 , and the cen...

Embodiment 2

[0045] The embodiment of the present invention is based on the bionic three-dimensional cobweb laminated tube heat exchanger combined and expanded along the circumferential array, and the shunt pipelines 2 of each heat exchanger unit are connected to each other and evenly distributed; or the heat exchanger is combined in an axial array Expansion, the outlet 5 of the previous heat exchanger unit communicates with the inlet 1 of the next heat exchange unit; it can also be expanded along the circumferential and axial arrays at the same time, such as Figure 7-8 As shown; on the premise that the installation difficulty does not increase, a variety of overall structural forms can be obtained, which are easy to disassemble, assemble and expand, have good combination characteristics and installation flexibility, and are suitable for different heat exchange requirements and different installation spaces; due to the six The polygons have a self-similar structure. On the premise of ensur...

Embodiment 3

[0047] In addition to regular hexagons, the shape of the mesh pipeline 3 can also be a regular polygon structure such as a regular triangle, a regular quadrilateral, and a regular pentagon. The multi-layer regular polygon mesh pipeline 3 forms a compact cross-flow structure, which is stable High performance, the structure of multiple bent tubes 6 is exactly the same, and the installation positions are symmetrical to ensure that the fluid is evenly distributed in the shunt pipeline 2 and the mesh pipeline 3. Under the conditions of the same volume and the same heat transfer, each bend The path of the folded tube 6 is the shortest, greatly reducing the pressure drop; it has a small mass in a limited volume, which can meet the installation requirements under small load requirements.

[0048] The first bending section 4 and the last bending section 4 of the bending pipe 6 are located on the same radius or on different radii of the circumcircle of the regular polygon, such as Figu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com