Microscopic imaging objective lens for fiber core identification of optical fiber fusion splicer and imaging method thereof

An optical fiber fusion splicing machine and microscopic imaging technology, which is applied in the direction of microscope, optical waveguide coupling, optics, etc., can solve the problems of unsatisfactory imaging performance, high difficulty, and large relative aperture, so as to ensure the efficiency and quality of fusion splicing, and ensure high Accurate alignment and reduced splice loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

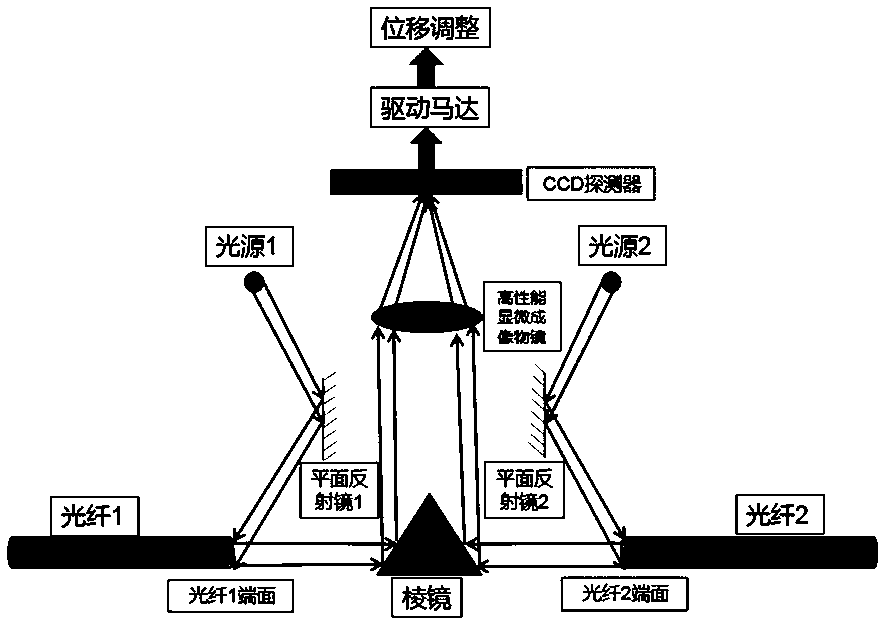

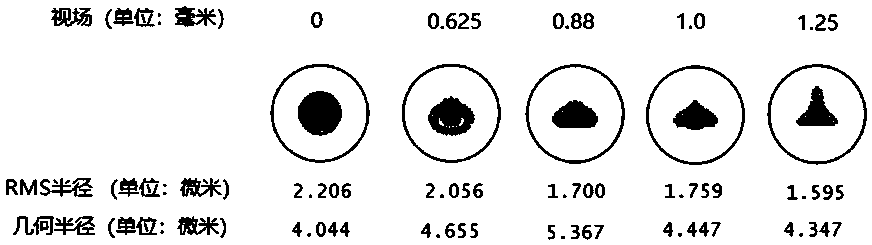

[0022] The technical solution of this embodiment is to provide a high-precision microscopic imaging objective lens for fiber core identification and alignment of an optical fiber fusion splicer. Its working band is 780-820nm, the system numerical aperture is 0.21, and the field of view is 2.5mm.

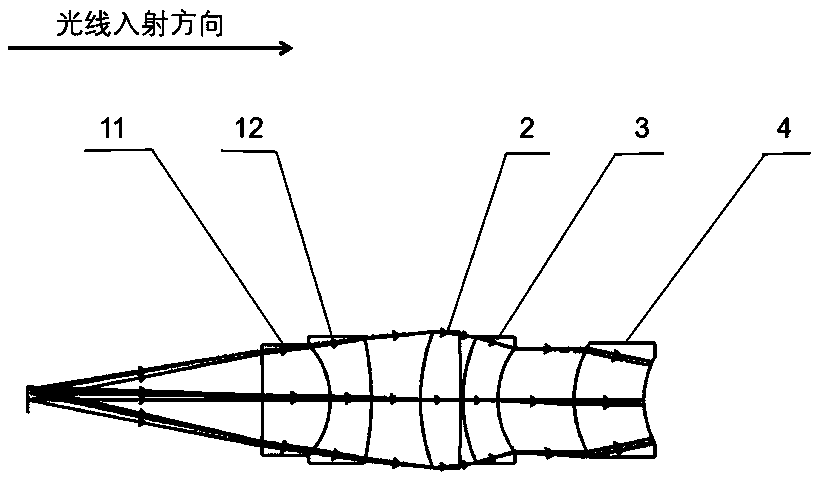

[0023] See attached figure 2 , which is the imaging optical path diagram of the microscopic imaging objective lens used for fiber core identification and alignment of the fiber fusion splicer provided by this embodiment; A meniscus spherical lens separated by blocks is formed, along the incident direction of the light, followed by a concave-convex spherical positive lens 11 of a doublet lens; a meniscus spherical negative lens 12 of a doublet lens; a double-convex spherical positive lens 2; a meniscus spherical surface Negative lens 3; meniscus spherical thick positive lens 4.

[0024] The aperture stop is located on the rear surface of the biconvex spherical positive lens 2, the f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tube length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com