Large-area photomultiplier with hybrid electron multiplication system

A technology of photomultiplier tube and electron multiplication, which is applied in the direction of electron multiplier dynode, electron multiplier tube, electron multiplier detailed information, etc. It can solve the problems of low collection efficiency, performance indicators such as affecting detection efficiency, and low electron collection efficiency. , to achieve the effect of improving collection efficiency, high electron gain, and preventing overflow loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Specific embodiments of the present invention will be described in detail below. It should be noted that the embodiments described here are for illustration only, and are not intended to limit the present invention.

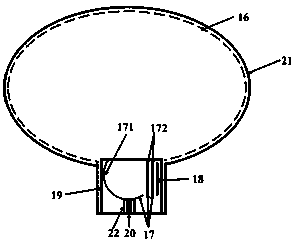

[0029] figure 1 It is a structural schematic diagram of an embodiment of a large-area photomultiplier tube with a hybrid electron multiplication system in the present invention.

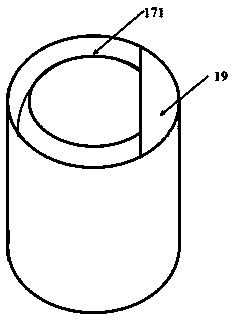

[0030] like figure 1 As shown, a large-area photomultiplier tube with a hybrid electron multiplication system of the present invention mainly includes a photocathode 16, an electron multiplication system 17, an anode 18, a shielding barrel 19, and power supply and signal lead wires 20. The above-mentioned components of the photomultiplier tube of the present invention are all placed in the vacuum glass container 21, and the vacuum glass container can be spherical or ellipsoidal, and the specific shape depends on the requirements of the photoelectron transit time dispersion in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com