Complete machine structure type of 360-degree full-rotation board internal and external double-machine-contra-rotating propulsion device

A technology of complete machine structure and propulsion device, which is applied in the direction of outboard propulsion device, propulsion device engine, engine using propulsion device combination, etc., and can solve the problems such as the vertical arrangement of the electric motor, the electric motor, and the weight that are not mentioned , to achieve the effect of light weight, small mechanical loss and small size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

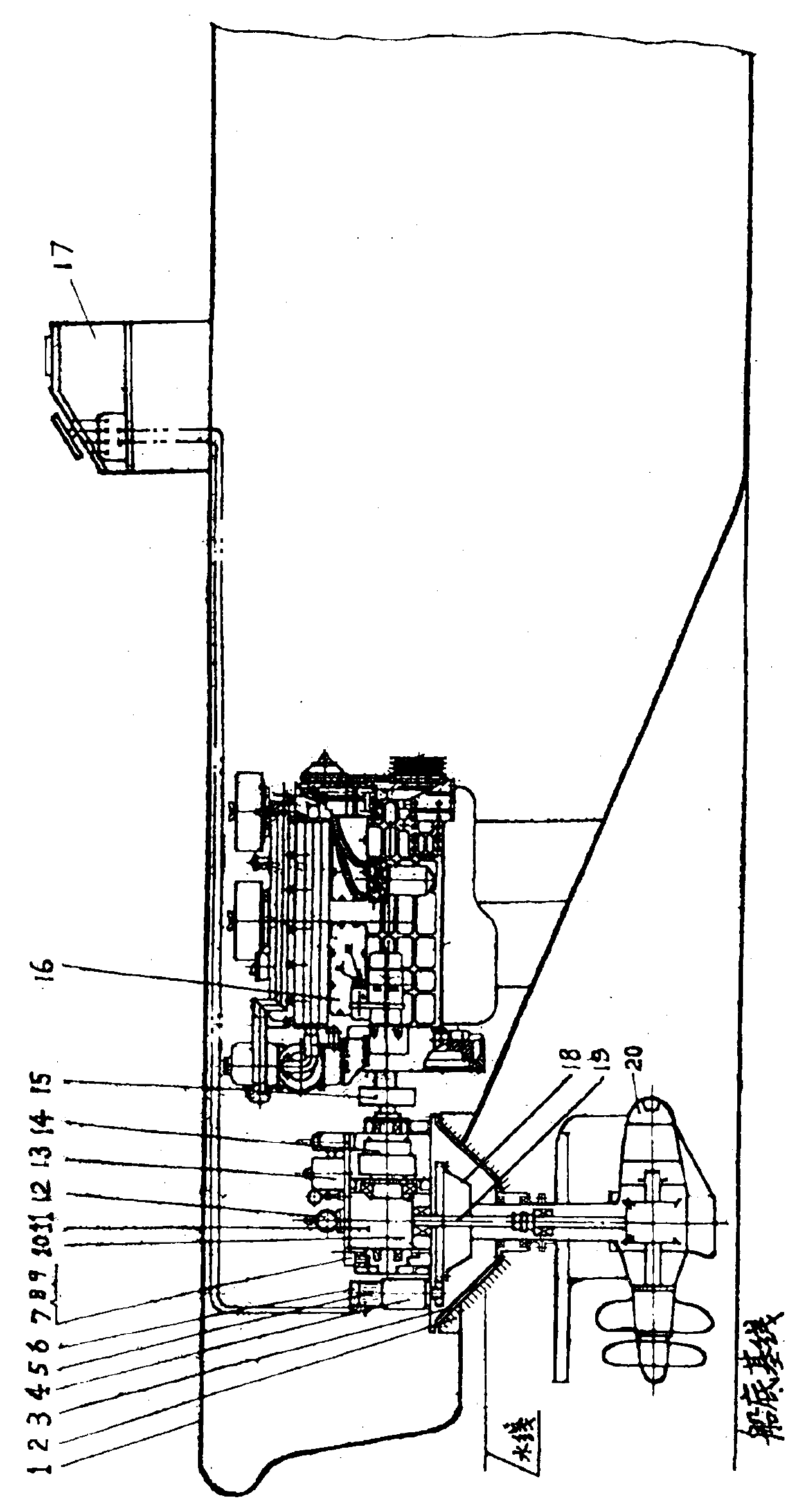

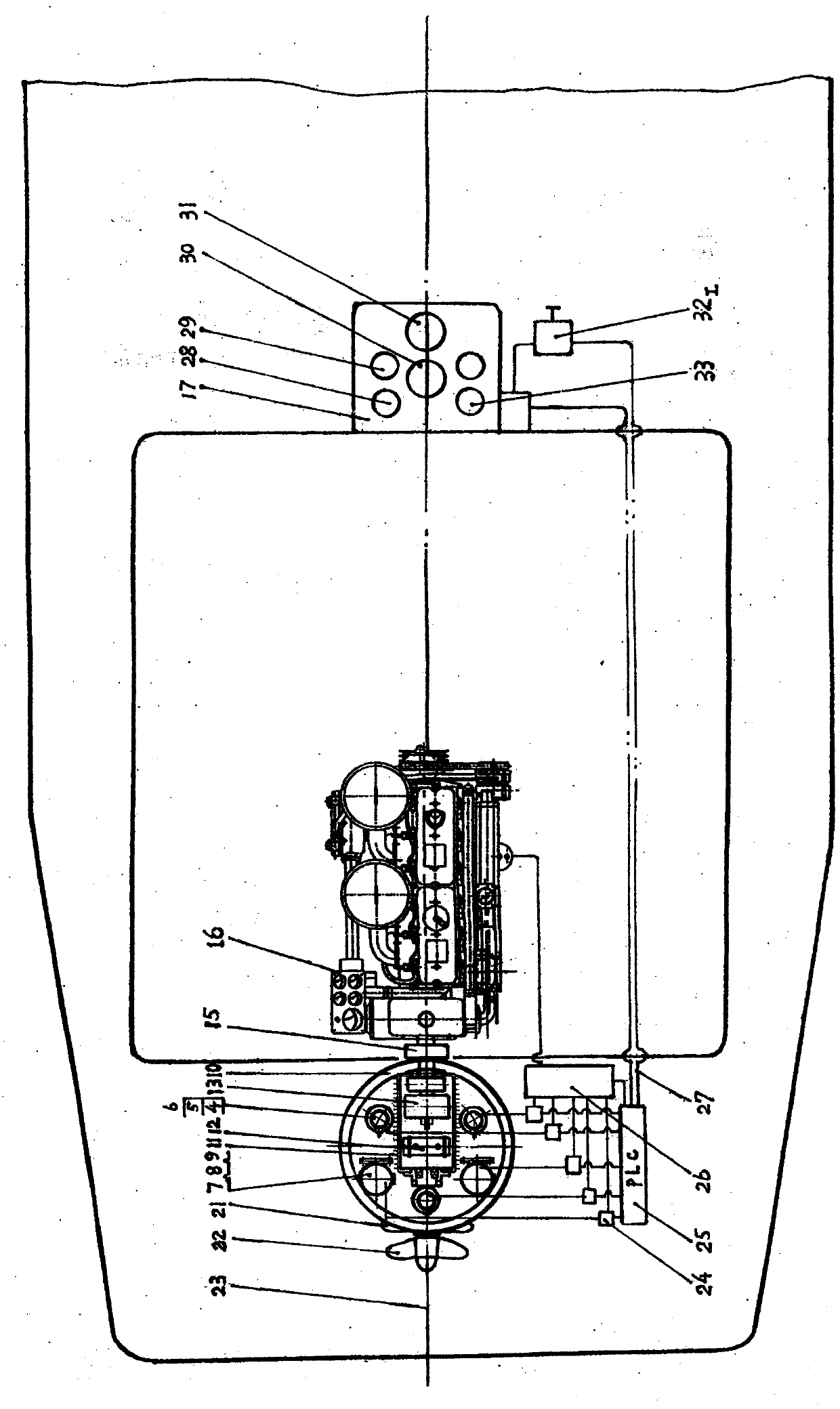

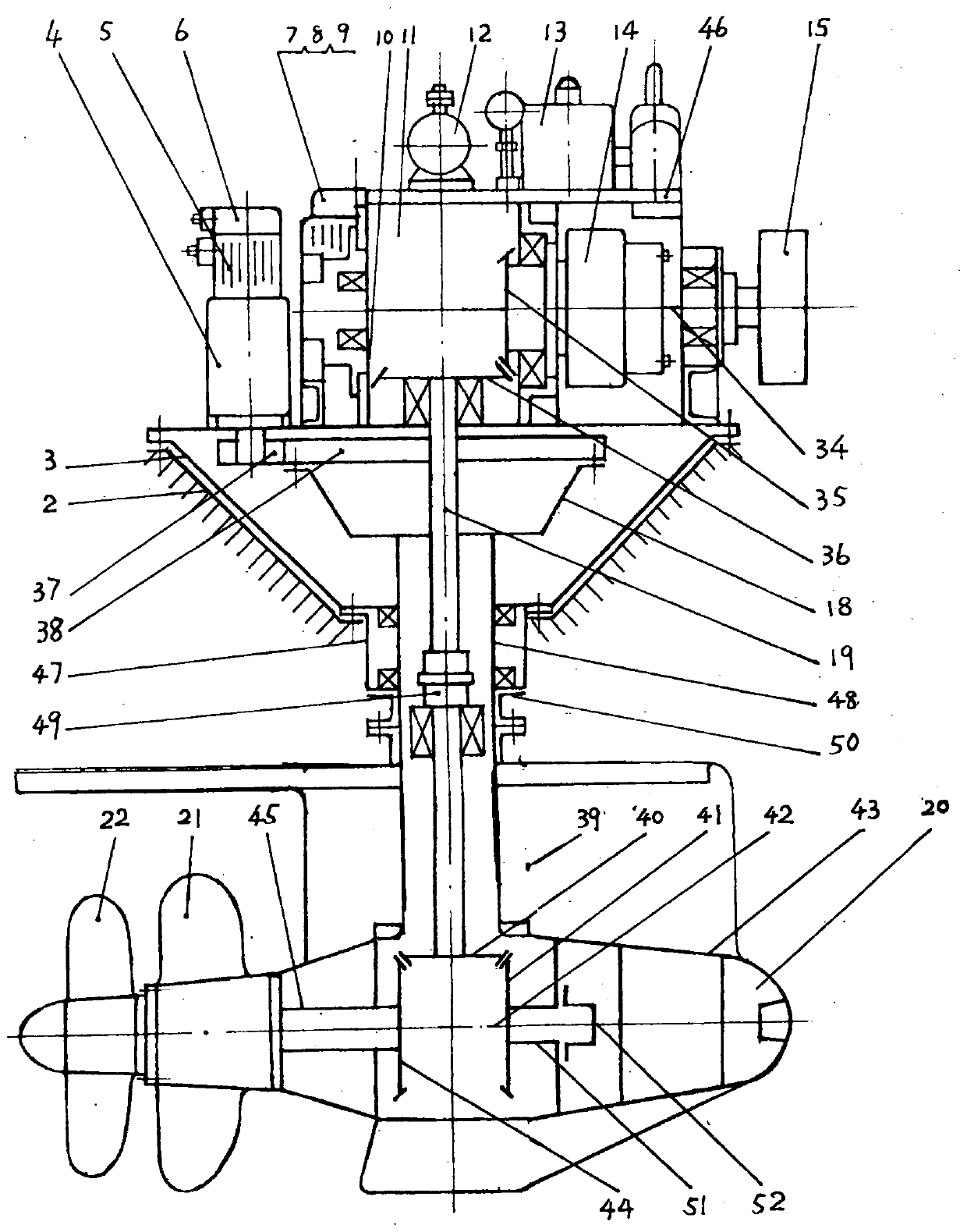

[0074] see figure 1 , when the diesel engine is used as the main engine, the structure of the 360° full-rotation inboard and outboard dual-engine counter-rotating propulsion device of the present invention includes: the paddle rudder rotating body 18 fixed at the stern of the ship, and the protective paddle rudder rotating body 18 fixed at the stern of the ship The Huff-type square box composed of the upper and lower shells 11 and 10 with additional cooling fins on the shell 2 is screwed with the circular plate base 10 as the upper part of the bracket and the lower conical bracket 3 to drive the inside of the propeller rudder rotator 18. The first transmission chain of the intermediate drive shaft 19 drives the second transmission chain of the rotary part of the paddle rudder rotary body 18, and the 360° full-turn dual-machine synchronous and non-synchronous 25 modes run the electronic control drive mechanism 17 and connect with the prime mover The highly elastic coupling 15. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com