Ilepcimide oral instant film agent and preparation method thereof

A technology of oral instant film and solubilizer, which is applied in the direction of pharmaceutical formulas, medical preparations with non-active ingredients, medical preparations containing active ingredients, etc., which can solve the problems of inability to cover taste, poor compliance of children, and failure to achieve the taste and other problems, to achieve the effect of good taste, good compliance and fast onset of action

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0042] The present invention also provides a method for preparing the above-mentioned ileexamine oral instant film, which comprises the following steps:

[0043] A) Mix the ilesiamine and the solubilizer, and then extrude and granulate to obtain a solid dispersion of ilesiamine;

[0044] Mixing the film-forming agent with warm water at 50-70°C to obtain a polymer gel, and mixing the polymer gel, plasticizer, disintegrant and flavoring agent to obtain a glue liquid;

[0045] B) Mixing the ilexamide solid dispersion and the glue solution to obtain a drug-containing solution;

[0046] C) Carrying out vacuum degassing treatment on the drug-containing solution, forming a film, and drying to obtain an oral quick-dissolving film of ilexamide.

[0047] In the preparation method of the instant oral film of ilexamine provided by the present invention, the components and proportions of the raw materials used are the same as the above, and will not be repeated here.

[0048] In the present invention...

Embodiment 1

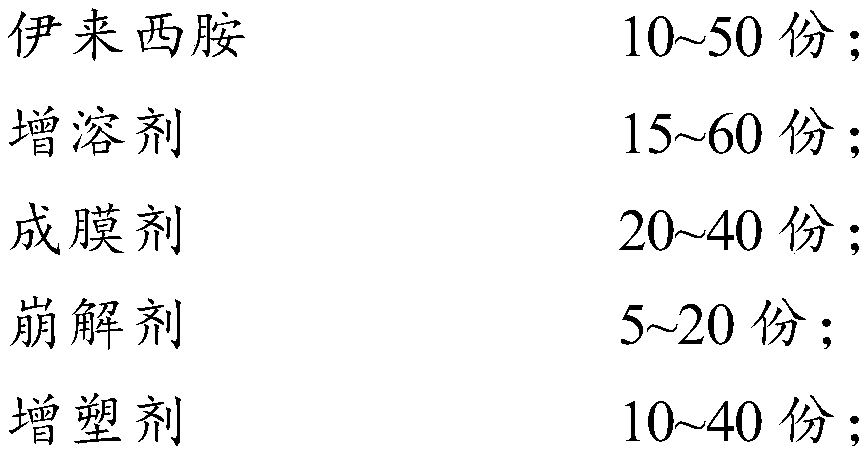

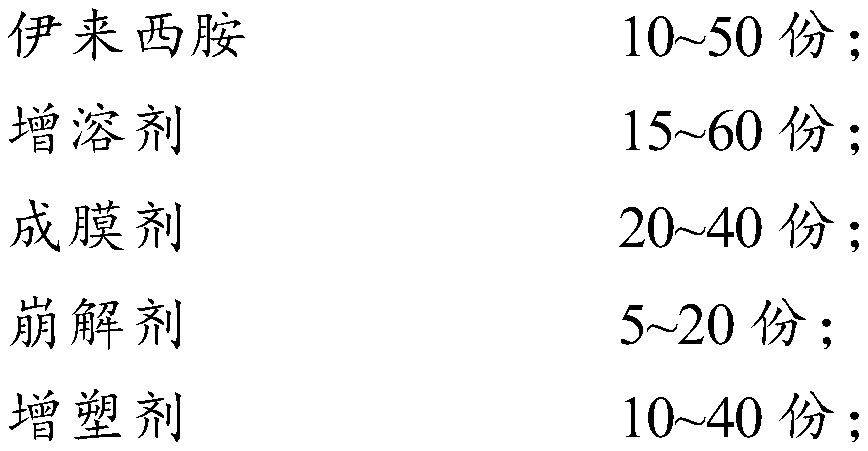

[0075] Table 1 Example 1 Ingredients and contents of each raw material

[0076]

[0077]

[0078] Preparation:

[0079] 1) Ileexamine raw material and the solubilizer copovidone S-630 are mixed uniformly in a mixer, and the hot-melt extruding machine pellets are added, the temperature is controlled at 110°C, the screw speed is controlled at 55rpm, and the Ilexiamine solid dispersion is prepared. ,spare.

[0080] 2) Under stirring, the film-forming agent copovidone S-630 is placed in warm water at 60° C. to obtain a polymer gel; the dosage ratio of the film-forming agent to the warm water is 1 g: 10 mL.

[0081] 3) Under stirring, add plasticizer propylene glycol, disintegrant croscarmellose sodium (CCNa), and flavoring agent strawberry flavor to the copovidone S-630 polymer gel, and stir well.

[0082] 4) Under the stirring state, add the solid dispersion of ilexamine and stir evenly to obtain a drug-containing solution.

[0083] 5) Vacuum degassing the chemical solution to form a film ...

Embodiment 2

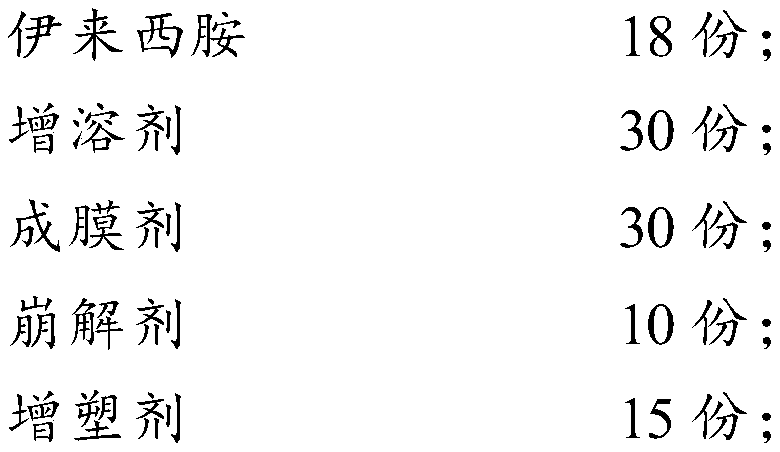

[0087] Table 2 Example 2 Each raw material component and content

[0088]

[0089]

[0090] Preparation:

[0091] 1) Ilexiamine raw material and the solubilizer copovidone S-630 are mixed uniformly in a mixer, and the hot-melt extruder granules are added, the temperature is controlled at 103℃, the screw speed is controlled at 40rpm, and the Ilexiamine solid dispersion is prepared. ,spare.

[0092] 2) Under stirring, the film-forming agent copovidone S-630 is placed in warm water at 70° C. to obtain a polymer gel; the dosage ratio of the film-forming agent to the warm water is 1 g: 15 mL.

[0093] 3) Under stirring, add plasticizer propylene glycol, disintegrant croscarmellose sodium (CCNa), and flavoring agent sweet orange flavor to the copovidone S-630 polymer gel, and stir evenly.

[0094] 4) Under the stirring state, add the solid dispersion of ilexamine and stir evenly to obtain a drug-containing solution.

[0095] 5) Vacuum degassing the chemical solution to form a film (the film t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com