Preparation methods of poly-l-lactide particles and injectable soft tissue filler

A poly-L-lactic acid and soft tissue technology, applied in the field of medicine, can solve the problems of complex poly-L-lactic acid particle process, difficult product purification, unfavorable scale-up production, etc., and achieves excellent water-phase easy dispersibility, low production cost, and long retention period. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

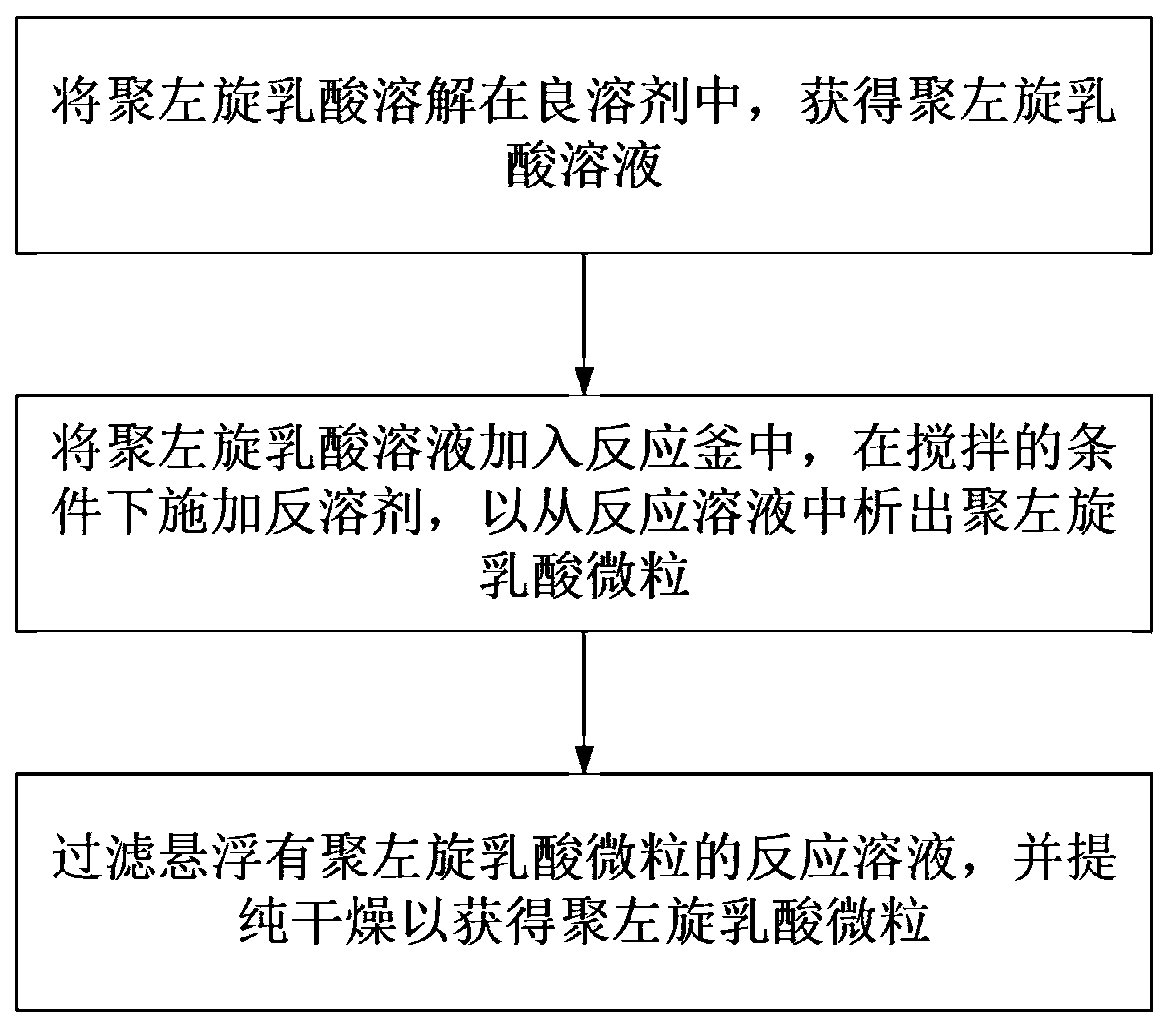

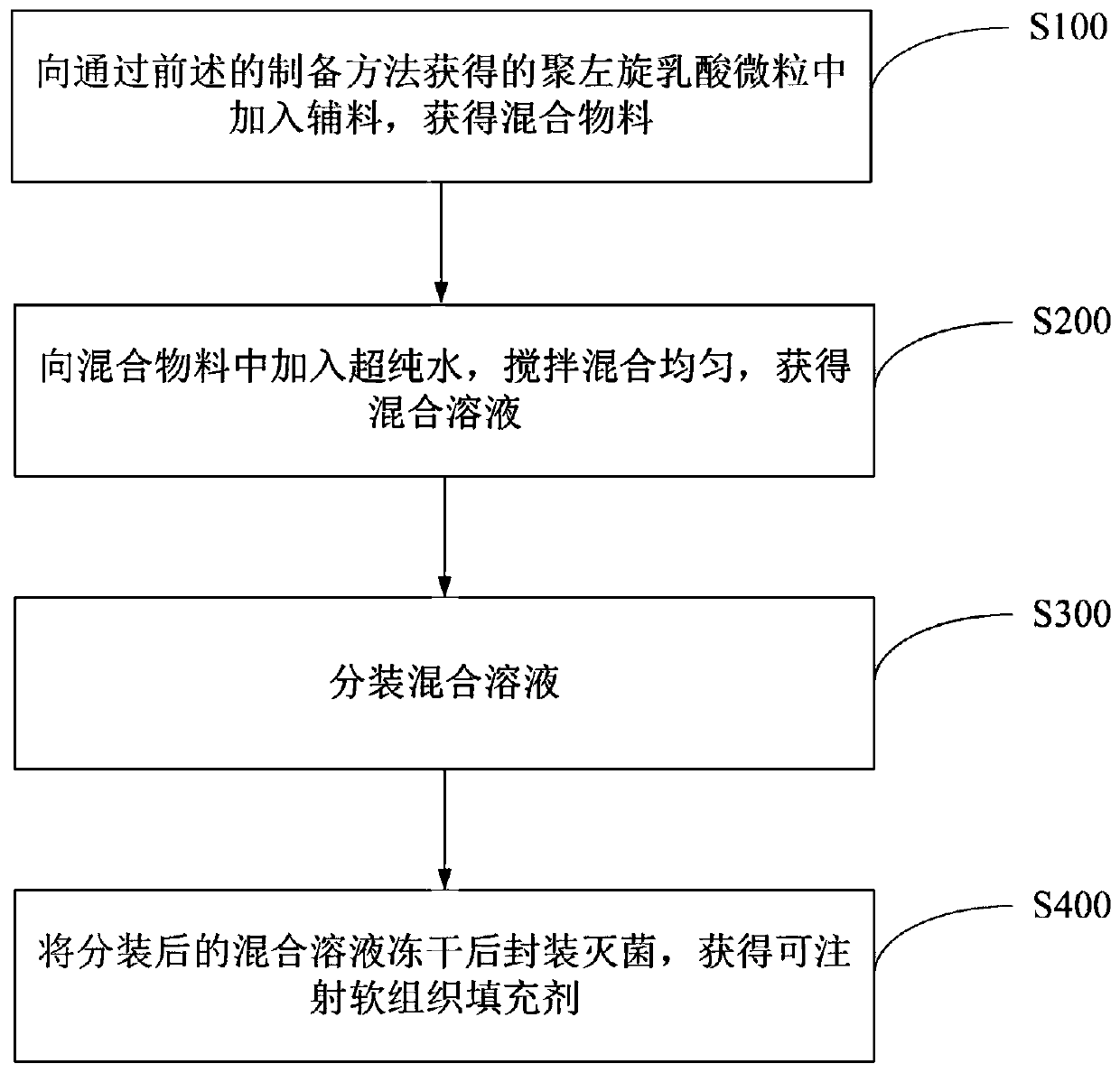

[0049] figure 1 A schematic flow chart showing a method for preparing poly-L-lactic acid microparticles according to an embodiment of the present invention. Such as figure 1 Shown, this preparation method comprises:

[0050] Step 1, dissolving poly-L-lactic acid in a good solvent to obtain a poly-L-lactic acid solution;

[0051]Step 2, adding the poly-L-lactic acid solution into the reaction kettle, and applying an anti-solvent under the condition of stirring, so as to separate the poly-L-lactic acid particles from the reaction solution;

[0052] Step 3, filtering the reaction solution in which the poly-L-lactic acid microparticles are suspended, and purifying and drying to obtain the poly-L-lactic acid microparticles.

[0053] In step one, the molecular weight of poly-L-lactic acid can be 3KDa, 10KDa, 20KDa, 50KDa, 100KDa, 150KDa or 200KDa, or any other value in the range of 3-200KDa. The poly-L-lactic acid with this molecular weight can be purchased directly on the marke...

Embodiment 1

[0079] The embodiment of the present invention provides a preparation method of poly-L-lactic acid microparticles, the preparation method comprising the following steps:

[0080] 1) Weigh 20g of poly-L-lactic acid with a molecular weight of 20KDa, dissolve it in 1.2L of dichloromethane solvent, and configure it into a 0.016g / mL polylactic acid solution;

[0081] 2) Add the poly-L-lactic acid solution into the reaction kettle with magnetic stirring, and drop the ethanol anti-solvent into the reaction kettle with the speed of 100mL / min through the peristaltic pump under the magnetic stirring of 600rpm, and drop the total amount of the ethanol anti-solvent The volume is 6L. When the amount of ethanol added reaches a certain volume, poly-L-lactic acid particles will precipitate out in the reaction kettle;

[0082] 3) Pour the reaction solution in which poly-L-lactic acid particles are suspended into a 100-mesh stainless steel screen, and filter to obtain poly-L-lactic acid particl...

Embodiment 2

[0088] The embodiment of the present invention provides a preparation method of poly-L-lactic acid microparticles, the preparation method comprising the following steps:

[0089] 1) Weigh 50g of poly-L-lactic acid with a molecular weight of 70KDa, dissolve it in 1.5L of chloroform solvent, and configure it into a 0.033g / mL polylactic acid solution;

[0090] 2) Add the poly-L-lactic acid solution into the reaction kettle with magnetic stirring, and drop the ethanol anti-solvent in the reaction kettle with the speed of 50mL / min through the peristaltic pump under the magnetic stirring of 400rpm, and add the total amount of the ethanol anti-solvent dropwise. The volume is 3L. When the amount of ethanol added reaches a certain volume, poly-L-lactic acid particles will precipitate out in the reaction kettle;

[0091] 3) Pour the reaction solution in which poly-L-lactic acid particles are suspended into a 500-mesh stainless steel screen, and filter to obtain poly-L-lactic acid partic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com