Metal and plastic integrated manufacturing method

A manufacturing method and metal technology, applied in the direction of coating, etc., can solve the problems of damage to the bonding strength of metal and plastic, less selectivity of plastic materials, and indentation on the metal surface, so as to improve surface oleophobicity, reduce product defect rate, and improve Effect of heat deflection temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

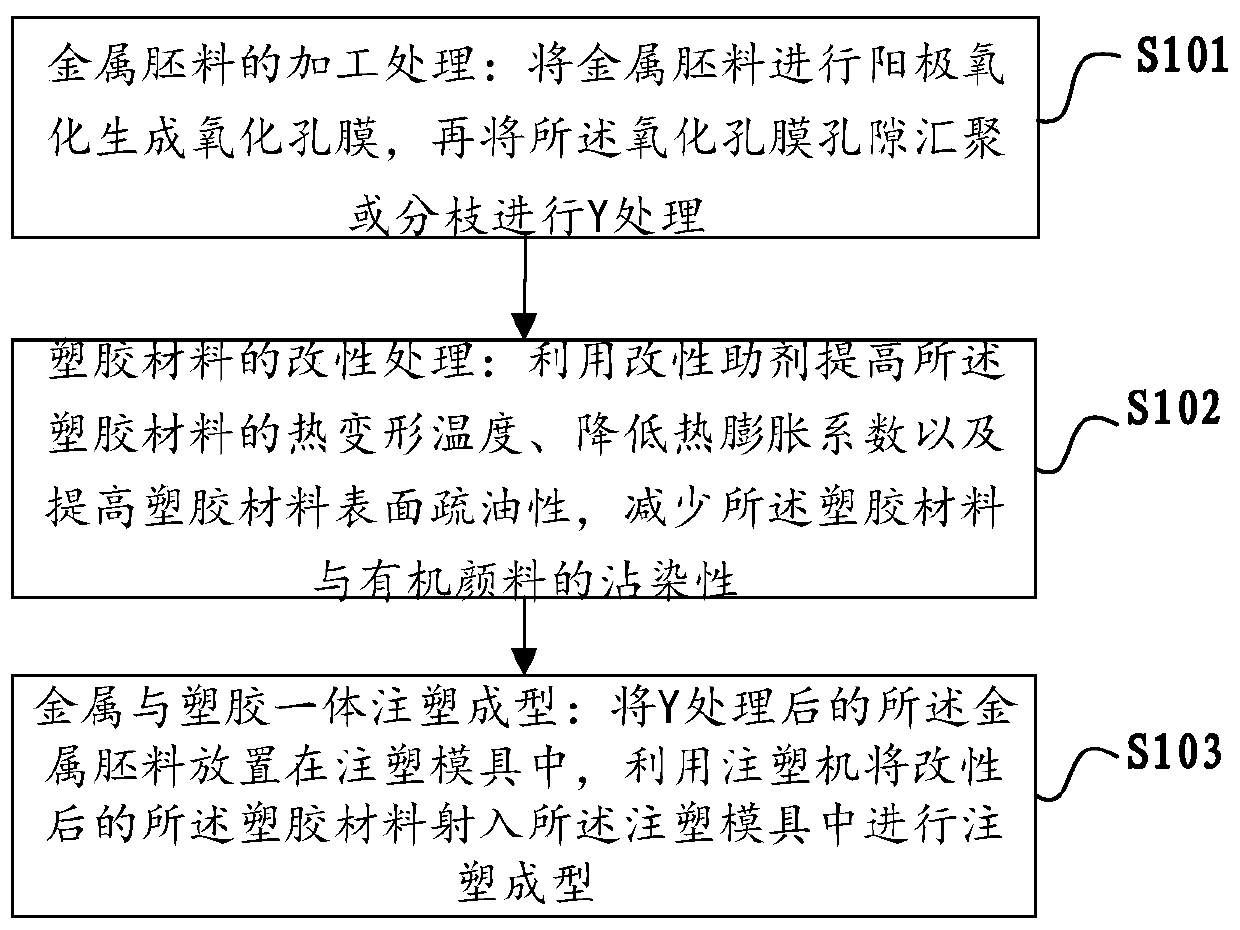

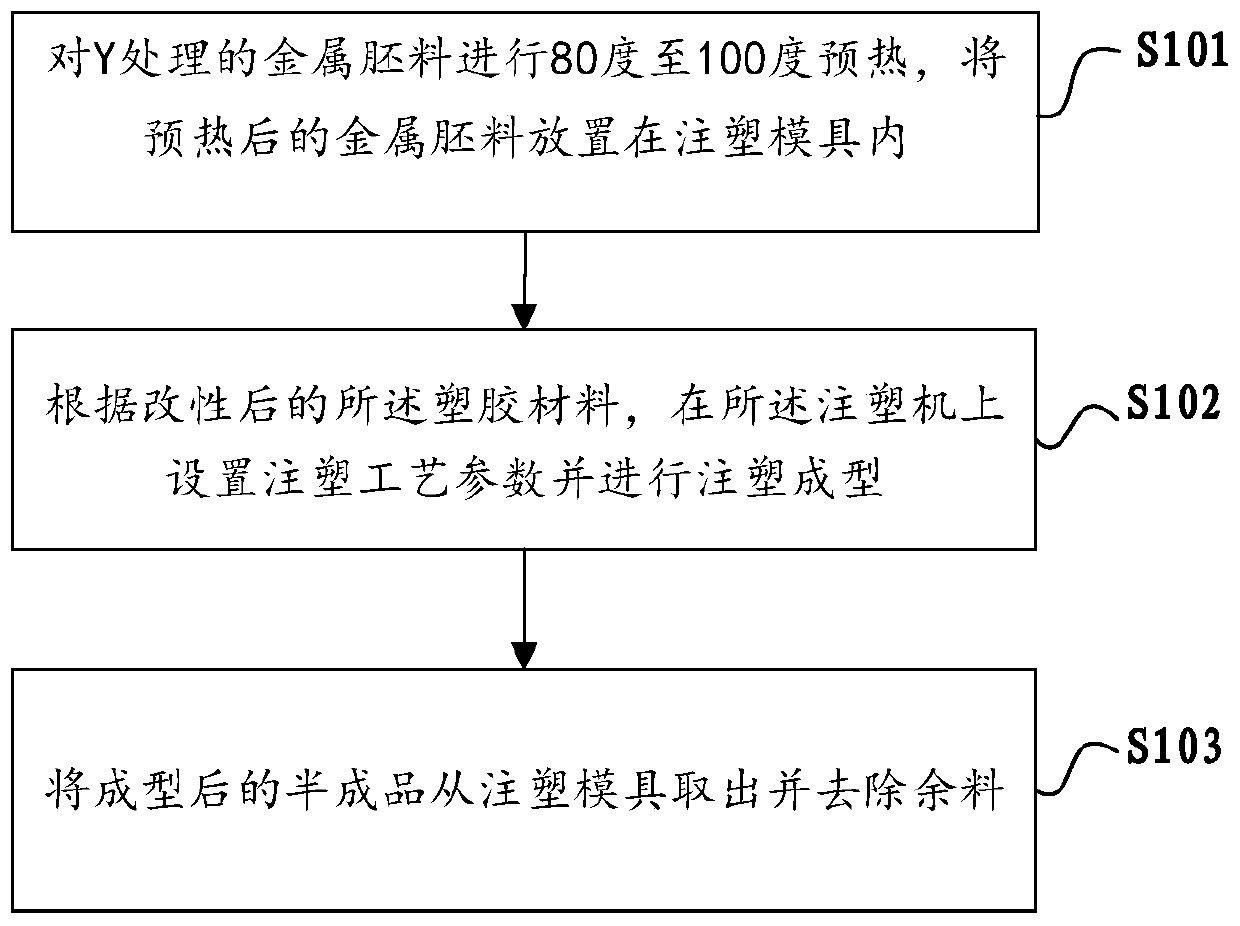

[0046] Such as figure 1 , 6 As shown, the embodiment of the present invention provides a metal and plastic integrated manufacturing method, including:

[0047] S101. Processing of the metal blank: anodizing the metal blank to form an oxidized pore film, and then performing Y treatment on the pores of the oxidized pore film by converging or branching;

[0048] S102. Modification treatment of plastic materials: using modification additives to increase the thermal deformation temperature of the plastic materials, reduce the thermal expansion coefficient and improve the surface oleophobicity of the plastic materials, and reduce the stainability of the plastic materials and organic pigments;

[0049] S103. Injection molding of metal and plastic: place the Y-treated metal blank in an injection mold, and use an injection molding machine to inject the modified plastic material into the injection mold for injection molding.

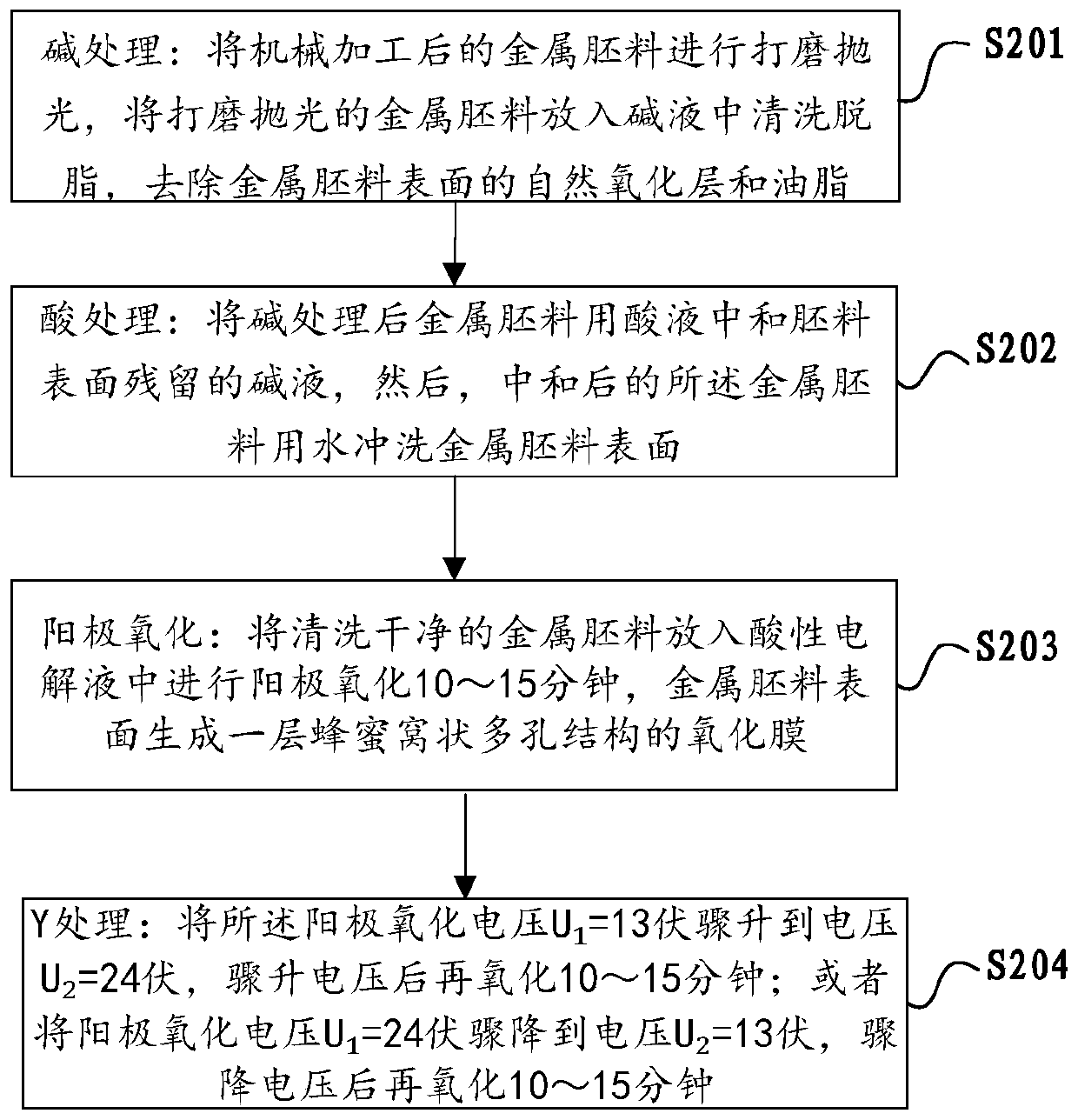

[0050] Such as figure 2 As shown, the steps of processin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com