Composite modified reinforced aging-resistant tungsten-tailing-containing ecological-sand-based water-permeable brick and preparation method thereof

A technology of composite modification and permeable bricks, which is applied in the field of building materials and can solve the problem of high cost of sand-based permeable bricks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

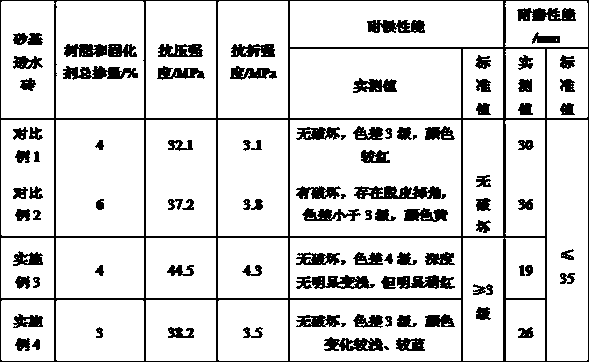

Examples

Embodiment 1

[0038] Prepare a film-modified tungsten tailings, the steps are as follows:

[0039] Take solid waste tungsten tailings, in which SiO 2 The content is greater than 85%, washed and dried, and passed through a 40-70 mesh sieve;

[0040] Put the dried and screened tungsten tailings into the sand mixer and heat to 180°C, add BASF styrene-acrylic resin 671 with 1.75% mass of tungsten tailings and stir fry for 80s, when the sand temperature drops to 110°C, add resin mass 0.6% silane coupling agent, stir for 10s, add 0.75% of tungsten tailings mass of Cytec CYMEL325 methyl etherified high imino cyanamide resin curing agent, stir for 60s, add 3% of resin mass of calcium stearate, stir Cool after 60s, crush and sieve to obtain film-coated modified tungsten tailings I.

Embodiment 2

[0042] Prepare a film-modified tungsten tailings, the steps are as follows:

[0043] Take solid waste tungsten tailings, in which SiO 2 The content is greater than 85%, washed and dried, and passed through a 40-70 mesh sieve;

[0044] Add the dried and screened tungsten tailings into the sand mixer and heat to 210°C, add BASF styrene-acrylic resin 671 with 1.05% mass of tungsten tailings and stir fry for 100s, when the sand temperature drops to 120°C, add resin mass 1.2% silane coupling agent, stir for 20s, add 0.45% tungsten tailings mass of Cytec CYMEL325 methyl etherified high imino cyanamide resin curing agent, stir for 120s, add 5% calcium stearate, stir for 180s Cooling, crushing and sieving to obtain film-coated modified tungsten tailings II.

Embodiment 3

[0046] To prepare an ecological sand-based permeable brick containing tungsten tailings, the steps are as follows:

[0047] First add 300kg of solvent-free e51 epoxy resin into the concrete forced mixer. While stirring, add 15.2kg of limestone powder and 11.4kg of nano-SiO 2 , 1.14kg of light stabilizer (770), 0.38kg of UV absorber and 19kg of silane coupling agent, continue to stir for 180s, carry out compound modification, then add 80kg of epoxy resin curing agent, stir for 90s, and finally add 10251kg of After the film-coated tungsten tailings I prepared in Example 1 were stirred for 90 s, they were uniformly distributed in the mold, and pressed for 5 s under a pressure of 20 MPa using a vibration forming press to obtain the sand-based permeable brick I.

[0048] In terms of mass percentage, the content of each component in the ecological sand-based permeable brick containing tungsten tailings prepared in this example is as follows: film-coated modified tungsten tailings I ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com