Microbial remediation agent based on bacterial strain 1JN2, and preparation and application methods thereof

A microbial remediation, 1JN2 technology, applied in the field of microbial remediation agents, can solve problems such as soil heavy metal pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

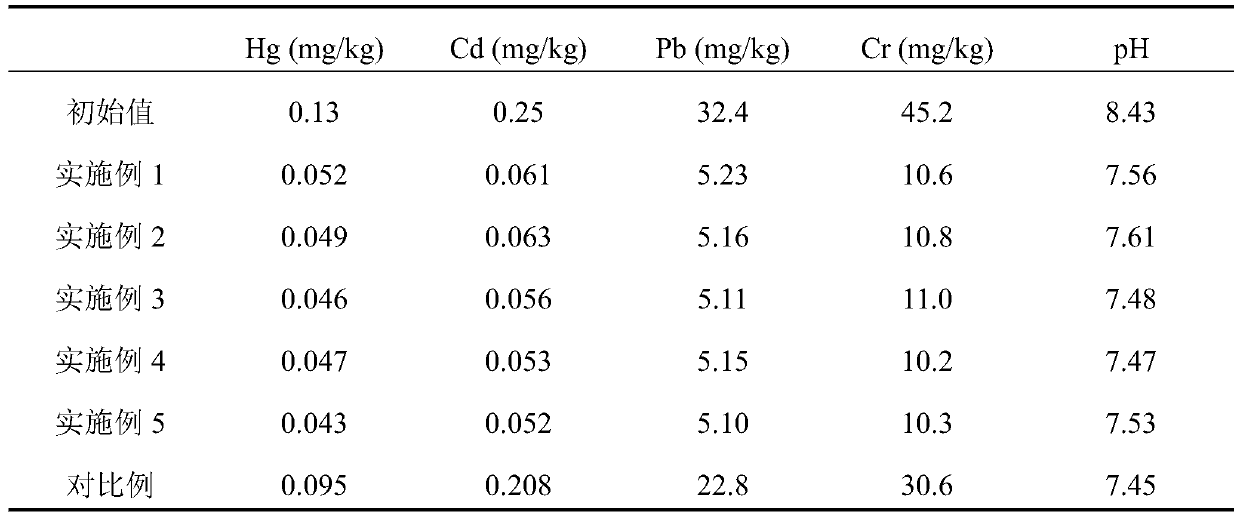

Examples

Embodiment 1

[0022] Take 50kg of microbial restoration agent based on strain 1JN2 as an example:

[0023] S1. Shake 50ml of the stress-resistant strain 1JN2 in 250ml of LB medium at 28°C and 180rpm for 16h, then centrifuge at 6000rpm for 10min, resuspend and dilute with 5500ml of sterilized water, add sterilized water to quantify to 6000ml, and obtain the stress-resistant strain agent;

[0024] S2. Mix and stir 5362ml of sterilized water, 120g of brown sugar, 12g of yeast extract powder and 6g of trace elements to obtain a culture medium, then add 300ml of the total weight of the culture medium to the EM bacteria stock solution, and place it in a fermenter at 30-35°C Cultivate for 2 days, add sterilized water to quantitatively reach 6000ml, and obtain EM bacterial agent;

[0025] S3. Mix 50 kg of crushed corn stalks and 50 kg of wheat stalks and place them in a muffle furnace, anoxic carbonization at 550° C. for 2 hours, and take out the black residue after the muffle furnace is cooled to...

Embodiment 2

[0030] Take 50kg of microbial restoration agent based on strain 1JN2 as an example:

[0031] S1. Shake 50ml of the stress-resistant strain 1JN2 in 250ml of LB medium at 28°C and 180rpm for 16h, then centrifuge at 6000rpm for 10min, resuspend and dilute with 5500ml of sterilized water, add sterilized water to quantify to 6000ml, and obtain the stress-resistant strain agent;

[0032] S2. Mix and stir 5362ml of sterilized water, 120g of brown sugar, 12g of yeast extract powder and 6g of trace elements to obtain a culture medium, then add 300ml of the total weight of the culture medium to the EM bacteria stock solution, and place it in a fermenter at 30-35°C Cultivate for 2 days, add sterilized water to quantitatively reach 6000ml, and obtain EM bacterial agent;

[0033] S3. Mix 50 kg of crushed corn stalks and 50 kg of wheat stalks and place them in a muffle furnace, anoxic carbonization at 550° C. for 2 hours, and take out the black residue after the muffle furnace is cooled to...

Embodiment 3

[0038] Take 50kg of microbial restoration agent based on strain 1JN2 as an example:

[0039] S1. Shake 50ml of the stress-resistant strain 1JN2 in 250ml of LB medium at 28°C and 180rpm for 16h, then centrifuge at 6000rpm for 10min, resuspend and dilute with 5500ml of sterilized water, add sterilized water to quantify to 6000ml, and obtain the stress-resistant strain agent;

[0040] S2. Mix and stir 5362ml of sterilized water, 120g of brown sugar, 12g of yeast extract powder and 6g of trace elements to obtain a culture medium, then add 300ml of the total weight of the culture medium to the EM bacteria stock solution, and place it in a fermenter at 30-35°C Cultivate for 2 days, add sterilized water to quantitatively reach 6000ml, and obtain EM bacterial agent;

[0041] S3. Mix 50 kg of crushed corn stalks and 50 kg of wheat stalks and place them in a muffle furnace, anoxic carbonization at 550° C. for 2 hours, and take out the black residue after the muffle furnace is cooled to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com