Preparation method of CuO-Cu2O/CM nanowire array heterostructure and application

A technology of nanowire arrays and heterogeneous structures, applied in measuring devices, material analysis through optical means, instruments, etc., can solve expensive and time-consuming problems, achieve low detection limits, good detection stability, and good stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

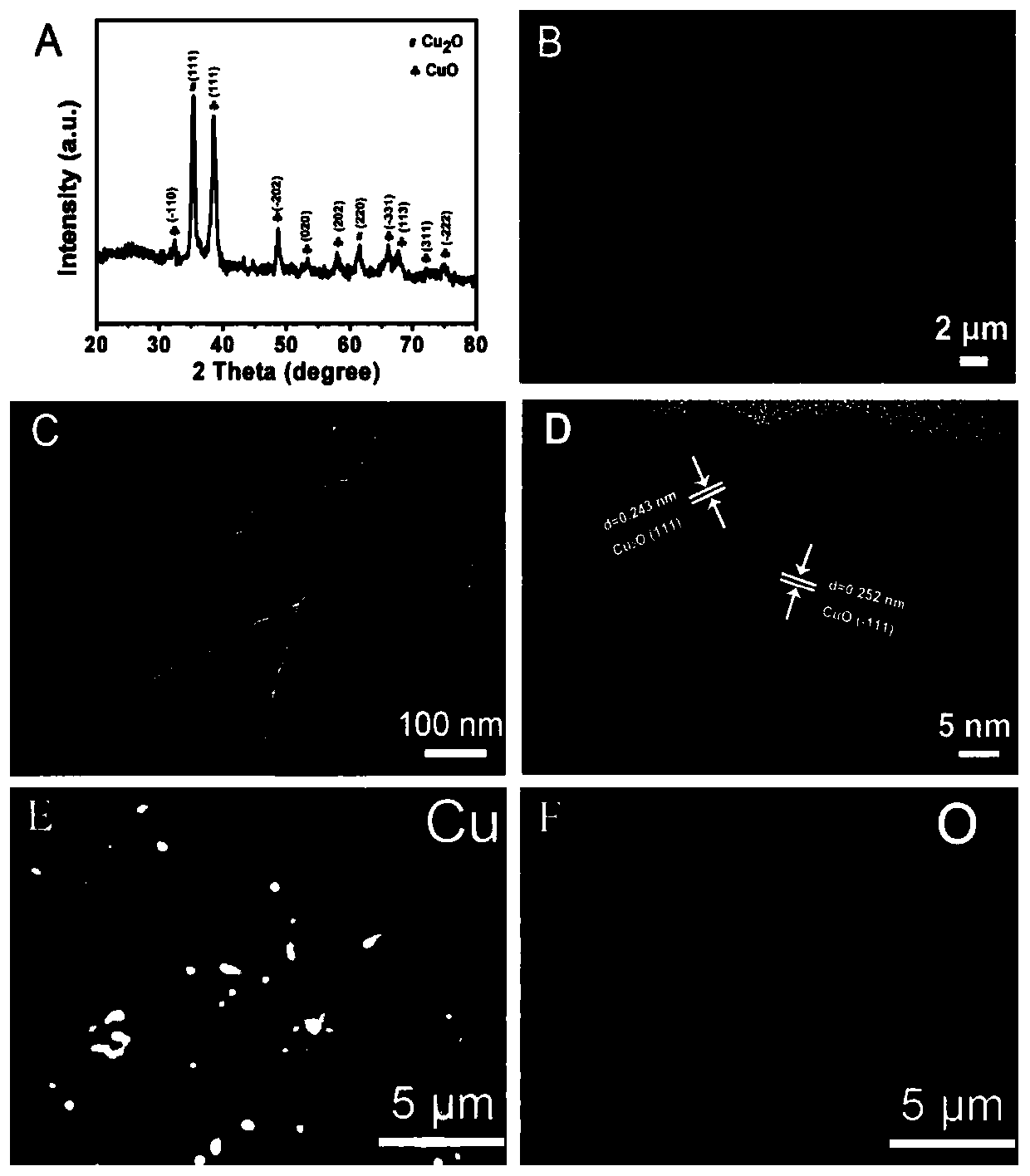

[0034] (1) Dissolve 3.2g NaOH and 0.91g ammonium persulfate in 25mL deionized water respectively, mix NaOH solution and ammonium persulfate solution, and stir for 5 minutes to obtain a clear solution; place the pretreated copper grid in the above clear solution Soak in medium for 20 minutes; take out the sample, wash with deionized water and ethanol respectively, and air-dry at 60°C to obtain Cu(OH) 2 precursor.

[0035] (2) The Cu(OH) prepared in step (1) 2 The precursors were calcined at 350 °C for 15 min in air. Take out the copper grid, and finally the obtained sample (CuO-Cu 2 O / CM) were washed several times with deionized water and dried in air.

Embodiment 2

[0037] (1) Dissolve 3.5g NaOH and 1.0g ammonium persulfate in 20mL deionized water respectively, mix NaOH solution and ammonium persulfate solution, and stir for 10 minutes to obtain a clear solution; place the pretreated copper grid in the above clear solution Soak in medium for 25 minutes; take out the sample, wash with deionized water and ethanol respectively, and air-dry at 60°C to obtain Cu(OH) 2 precursor.

[0038] (2) The Cu(OH) prepared in step (1) 2 The precursors were calcined at 350 °C for 20 min in air. Take out the copper grid, and finally the obtained sample (CuO-Cu 2 O / CM) were washed several times with deionized water and dried in air.

Embodiment 3

[0040] (1) Dissolve 3.3g NaOH and 0.95g ammonium persulfate in 23mL deionized water respectively, mix NaOH solution and ammonium persulfate solution, and stir for 8 minutes to obtain a clear solution; place the pretreated copper grid in the above clear solution Soak in medium for 23 minutes; take out the sample, wash with deionized water and ethanol respectively, and air-dry at 60°C to obtain Cu(OH) 2 precursor.

[0041] (2) The Cu(OH) prepared in step (1) 2 The precursors were calcined at 350 °C for 18 min in air. Take out the copper grid, and finally the obtained sample (CuO-Cu 2 O / CM) were washed several times with deionized water and dried in air.

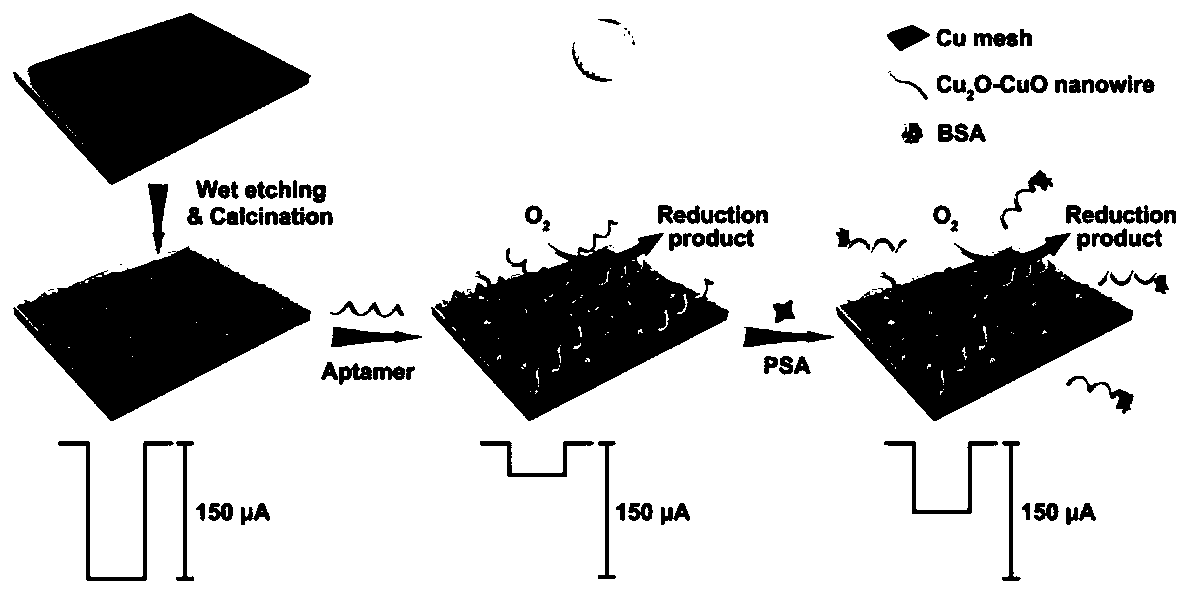

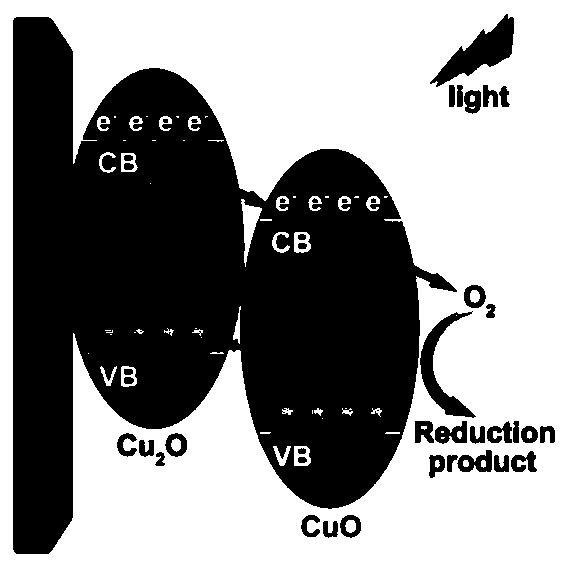

[0042] photoelectrochemical biosensor

[0043] The photoelectrochemical biosensor of the present invention comprises a working electrode connected to an electrochemical workstation, a reference electrode (Ag|AgCl|Cl - ), the counter electrode (platinum electrode), using a xenon lamp as a simulated light source, the working...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com