Method for removing Peru squid sucker ring teeth

A technology of Peruvian squid and ring teeth, which is applied in the field of fish processing, can solve the problems of difficulty in removing squid rings, and achieve the effect of low cost of removing teeth, high product quality and good appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

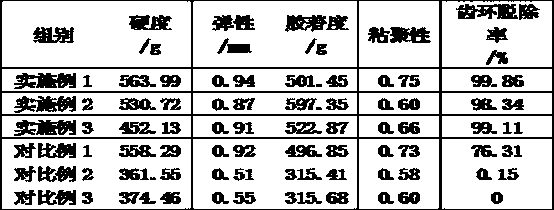

Examples

Embodiment 1

[0019] A method for removing the sucker ring teeth of Peruvian squid, which undergoes the following process steps:

[0020] (1) Raw material pretreatment: wash and drain the fresh Peruvian squid to obtain squid raw material and set aside;

[0021] (2) Controllable enzymolysis: Weigh the squid raw material obtained in step (1), and brush the semi-fluid enzymatic solution on the surface of the squid raw material, wherein the mass percentage of the semi-fluid enzymatic solution is: collagenase 3.5%, seaweed sodium nitrate 1.5%, guar gum 1.5%, carrageenan 2%, the rest is distilled water; under the condition of 35 ℃ for 8 hours, the squid skin breaks and the basal collagen is obvious The enzymatic hydrolysis is completed when exposed; the enzymatic hydrolyzed squid raw materials are cleaned, drained, and squid whiskers are obtained, which are set aside;

[0022] (3) Ultra-high pressure treatment: send the enzymatic hydrolyzed squid obtained in step (2) into an ultra-high pressure ...

Embodiment 2

[0026] A method for removing the sucker ring teeth of Peruvian squid, which undergoes the following process steps:

[0027] (1) Raw material pretreatment: wash and drain the thawed Peruvian squid to obtain squid raw material and set aside;

[0028] (2) Controllable enzymolysis: Weigh the squid raw material obtained in step (1), and brush the semi-fluid enzymolysis liquid on the surface of the squid raw material, wherein, the mass percentage of the semi-fluid enzymolysis liquid is: papain 0.3%, pancreatic 0.2% protease, 0.2% flavor protease, 0.5% sodium alginate, 1% guar gum, 1.5% carrageenan, and the rest is distilled water; carry out controlled enzymatic hydrolysis at 25°C for 18 hours, and the The enzymatic hydrolysis is completed when the low part of the squid skin is broken and the basal collagen is obviously exposed; the squid raw materials after the enzymatic hydrolysis treatment are washed, drained, and the squid silk is obtained, and set aside;

[0029] (3) Ultra-high...

Embodiment 3

[0033] A method for removing the sucker ring teeth of Peruvian squid, which undergoes the following process steps:

[0034] (1) Raw material pretreatment: wash and drain the fresh Peruvian squid to obtain squid raw material and set aside;

[0035] (2) Controllable enzymatic hydrolysis: Weigh the squid raw material obtained in step (1), brush the semi-fluid enzymatic hydrolysis solution on the surface of the squid raw material, and carry out controlled enzymatic hydrolysis at 50°C for 24 hours, among which, the semi-fluid enzymatic hydrolysis The mass percentage of liquid is: neutral protease 2.5%, bromelain 2.5%, sodium alginate 3%, guar gum 3%, carrageenan 5%, and the rest is distilled water; When the skin is broken and the basal collagen is obviously exposed, the enzymatic hydrolysis is completed; the squid raw materials after the enzymatic hydrolysis treatment are washed, drained, and the squid silk is obtained, which is set aside;

[0036] (3) Ultra-high pressure treatmen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com