Method for preparing biobrick by inducing calcium carbonate deposition through microorganisms

A bio-brick and calcium carbonate technology, which is applied in the field of preparing bio-bricks by using microorganisms to induce calcium carbonate deposition, can solve the problems of preparing bio-bricks by calcium carbonate deposition, and achieve the effects of high compressive strength, good environmental tolerance, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

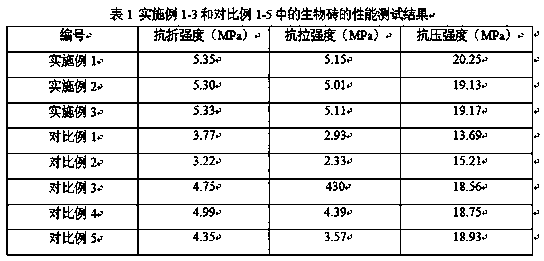

Examples

Embodiment 1

[0031] A method for preparing bio-bricks by using microorganisms to induce calcium carbonate deposition, comprising the following steps:

[0032] S1. Use culture solution (glucose 20 g / L, ammonium chloride 4.048 g / L, nickel sulfate 2 grains / L, peptone 1 g / L, solvent is water) to separate Bacillus pasteurianus (BNCC 337394) and pseudostrongia Bacillus (BNCC 132711) cultured to 1 × 10 6 cfu / mL, mix the obtained Bacillus pasteurianus bacteria solution and Bacillus pseudostrongis bacteria solution at a volume ratio of 1:1 to obtain a composite bacteria solution;

[0033] S2. Mix the composite bacterial solution with the mixed saline solution (3 mol / L calcium lactate and 3 mol / L magnesium chloride), and 3 mol / L urea solution at a volume ratio of 1:1:1 to obtain a solidified solution;

[0034] S3. Mix the river sand with the above mixture at a material-to-liquid ratio (kg / L) of 1:4 after being screened with 22 meshes, and then add it at a weight ratio of river sand:quicklime=3:1 (u...

Embodiment 2

[0037] Compared with Example 1, the difference between Example 2 is that the mixing volume ratio of the Bacillus pasteurian bacteria liquid and the Bacillus pseudofaster bacteria liquid is 1:0.5.

Embodiment 3

[0039] Compared with Example 1, Example 3 differs in that: the mixing volume ratio of the Bacillus pasteurian bacteria liquid and the Bacillus pseudofaster bacteria liquid is 1:1.5.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com