Preparation method of tungsten block sample for glow discharge mass spectrometry detection

A technology of glow discharge mass spectrometry and tungsten blocks, which is applied in the preparation, sampling, and measuring devices of test samples, which can solve problems such as inability to directly prepare samples, and achieve the effect of reducing testing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

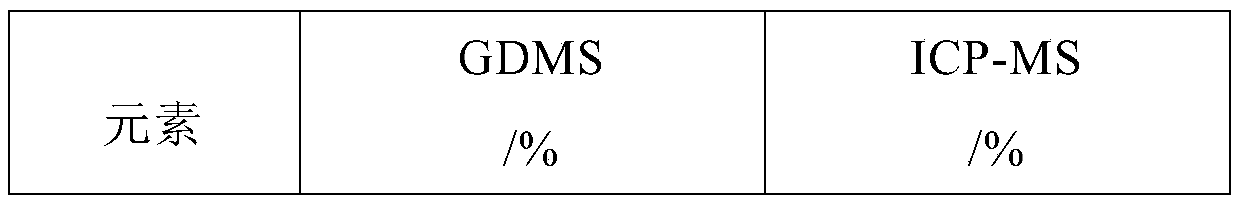

Embodiment 1

[0025] A preparation method for a tungsten block sample detected by glow discharge mass spectrometry comprises the following steps:

[0026] 1. Select the tungsten column with a diameter of 14mm, fix the tungsten column on the cutting machine for water-cooled cutting to prevent overheating, and obtain a tungsten column with a height of 20mm that is flat on both the upper and lower surfaces;

[0027] 2. Grind the upper end surface and the lower end surface of the tungsten column in the same direction with the 80-mesh silicon carbide sandpaper in the grinding machine. The speed of the grinding machine is controlled at 2800r / min until the upper end surface and the lower end surface of the tungsten column are uniform Flat, consistent grain direction;

[0028] 3. Use absolute ethanol to clean the tungsten column to remove the oil on the surface of the tungsten column;

[0029] 4. Place the tungsten column vertically in the center of the metallographic embedding machine, with the u...

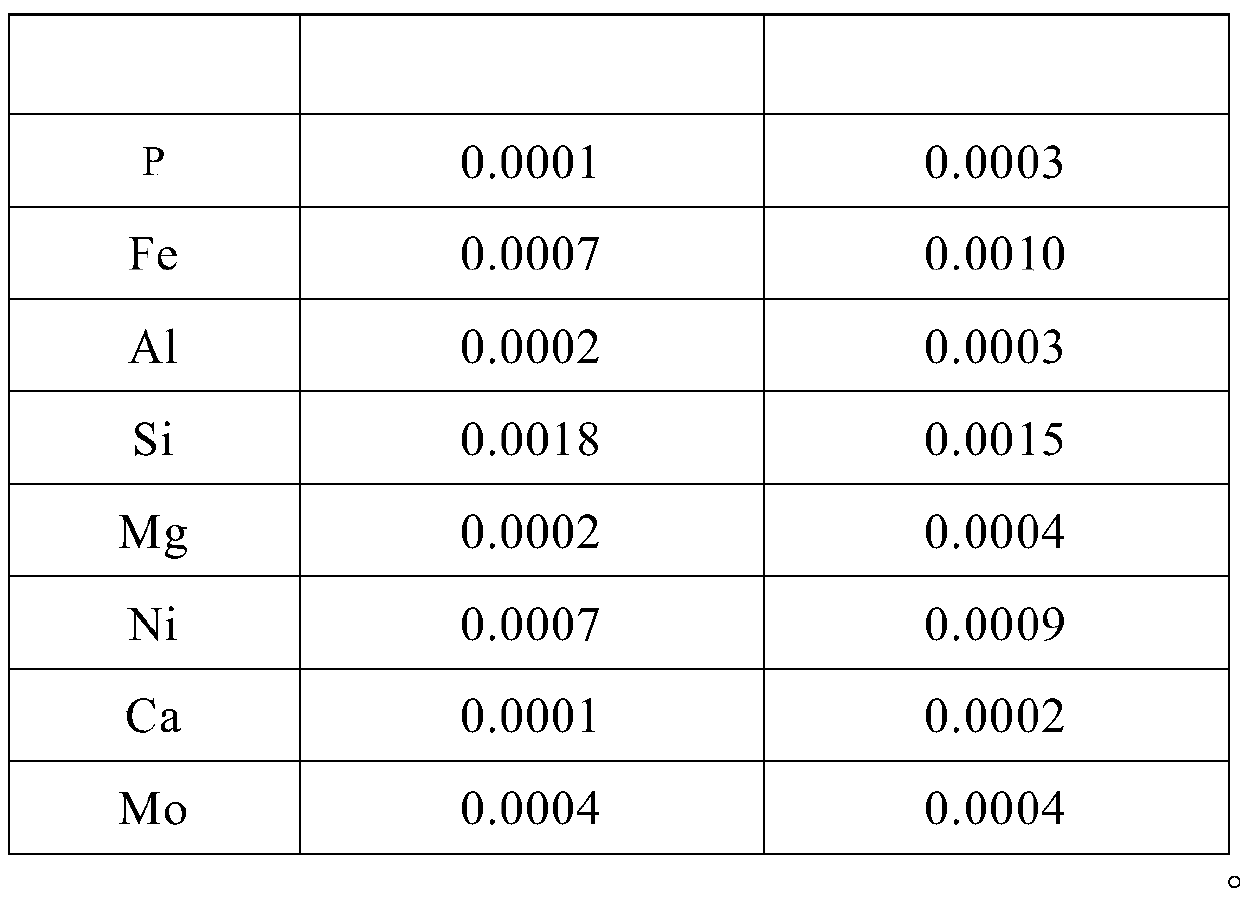

Embodiment 2

[0038] A preparation method for a tungsten block sample detected by glow discharge mass spectrometry comprises the following steps:

[0039] 1. Select the tungsten column with a diameter of 12mm, fix the tungsten column on the cutting machine for water-cooled cutting to prevent overheating, and obtain a tungsten column with a height of 26mm whose upper and lower end surfaces are both flat;

[0040] 2. Grind the upper end surface and the lower end surface of the tungsten column in the same direction with the 60-mesh silicon carbide sandpaper in the grinding machine. The speed of the grinding machine is controlled at 2800r / min until the upper end surface and the lower end surface of the tungsten column are uniform Flat, consistent grain direction;

[0041] 3. Use acetone to clean the tungsten column to remove the oil on the surface of the tungsten column;

[0042] 4. Place the tungsten column vertically in the center of the metallographic embedding machine, with the upper end o...

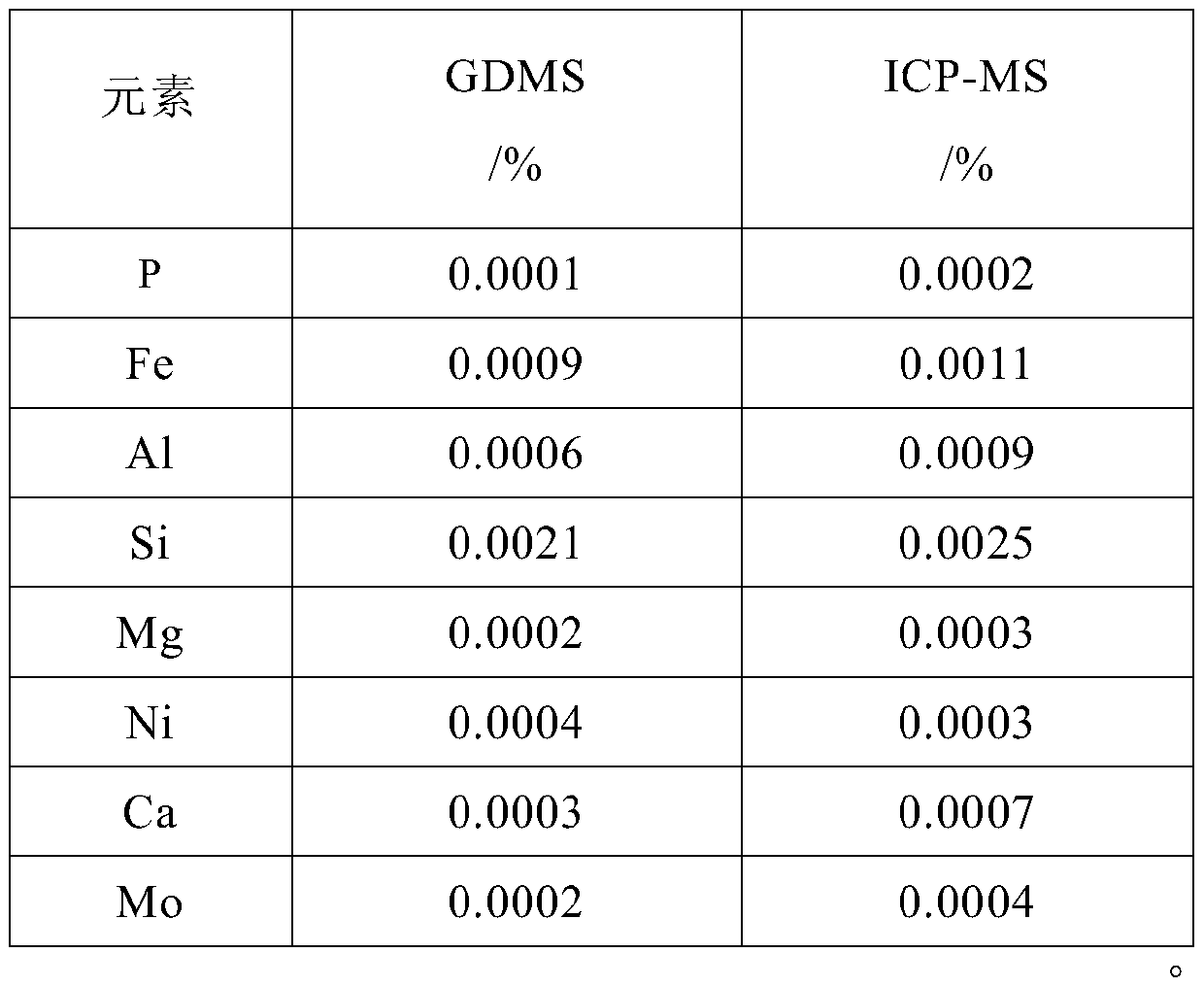

Embodiment 3

[0050] A preparation method for a tungsten block sample detected by glow discharge mass spectrometry comprises the following steps:

[0051] 1. Select the tungsten column with a diameter of 16mm, fix the tungsten column on the cutting machine for water-cooled cutting to prevent overheating, and obtain a tungsten column with a height of 15mm whose upper and lower end surfaces are both flat;

[0052] 2. Grind the upper end surface and the lower end surface of the tungsten column in the same direction through the 40-mesh silicon carbide sandpaper in the sample grinding machine. The speed of the grinding machine is controlled at 2800r / min until the upper and lower end surfaces of the tungsten column are uniform. Flat, consistent grain direction;

[0053] 3. Use carbon tetrachloride to clean the tungsten column to remove the oil on the surface of the tungsten column;

[0054] 4. Place the tungsten column vertically in the center of the metallographic embedding machine, with the up...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com