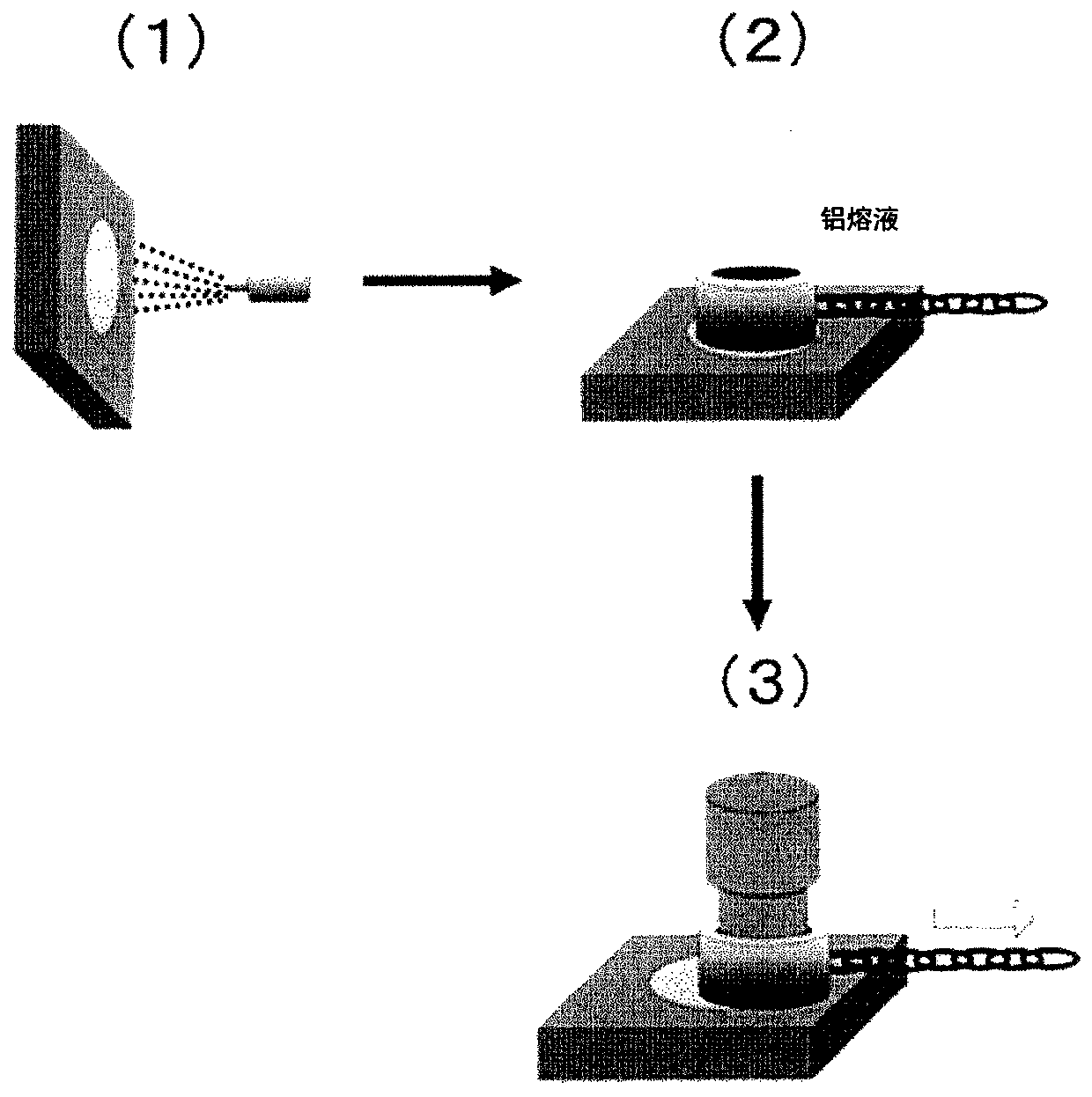

Mold release agent composition and die casting method

A technology of composition and release agent, which is applied in the direction of lubricating composition, casting mold, additives, etc., can solve the problems of mold temperature rise and release agent release performance reduction, etc., to shorten cycle time, improve productivity, and good mold release sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

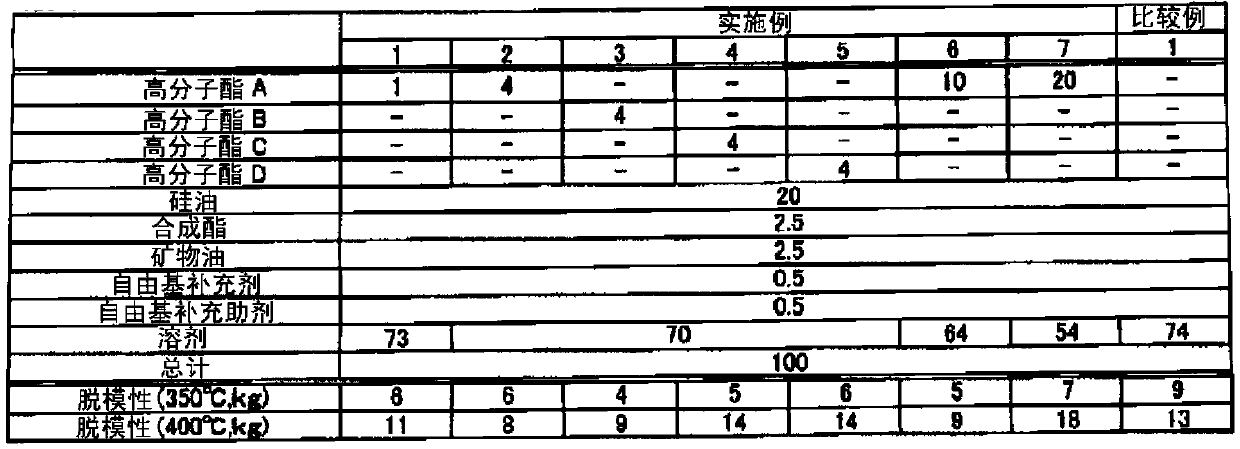

Embodiment 1~7、 comparative example 1

[0089] (Preparation of oily release agent composition)

[0090] The oil-based release agent composition described in Examples 1-7 and Comparative Example 1 was prepared with the composition (mass %) shown in Table 1. The release properties at 350°C and 400°C were evaluated for each oil-based release agent composition. The evaluation method of the releasability will be described later.

[0091] [Table 1]

[0092] (Table 1)

[0093]

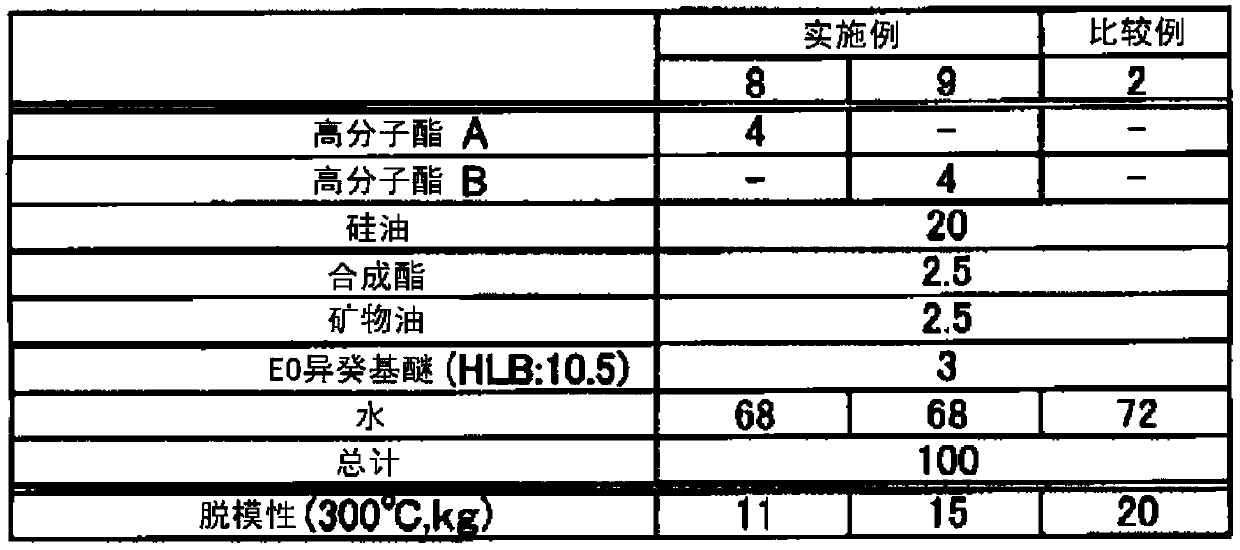

Embodiment 8、9、 comparative example 2

[0095] (Preparation of water-based release agent composition)

[0096] The aqueous release agent composition described in Examples 8 and 9 and Comparative Example 2 was prepared with the composition (mass %) shown in Table 2. The release properties at 300° C. were evaluated for each aqueous release agent composition. The evaluation method of the releasability will be described later.

[0097] [Table 2]

[0098] (Table 2)

[0099]

[0100] Polymer esters A, B, C, and D in Tables 1 and 2 each have the structures shown below.

[0101] Polymer ester A: The polyester structure formed by the dehydration condensation of trimethylolpropane and adipic acid is used as the main chain of the polymer, and the side chain has alcohol residues derived from trimethylolpropane and coconut High molecular weight ester of ester structure formed by dehydration and condensation of oil fatty acid

[0102] Polymer ester B: The polyester structure formed by the dehydration condensation of penta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Dynamic viscosity | aaaaa | aaaaa |

| Dynamic viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com