Covalent organic framework material connected through hydrazone bond and preparation method and application thereof

A technology of covalent organic frameworks and covalent organic frameworks, applied in chemical instruments and methods, water/sludge/sewage treatment, water pollutants, etc., can solve problems such as instability and poor chemical stability, and achieve reaction conditions Mild, high specific surface area, green and flexible preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

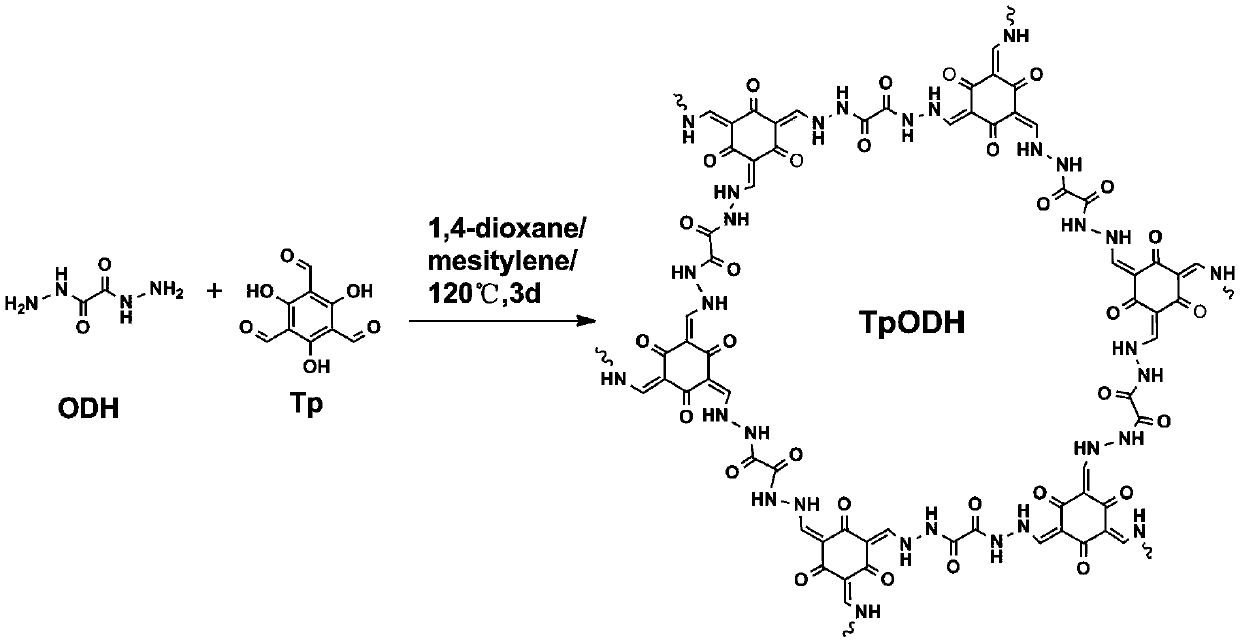

[0029] 1. Add 21mg of oxalodihydrazide to a 5mL ampoule.

[0030] 2. Add 17.71 mg of 1,3,5-trialdehyde phloroglucinol to the above centrifuge tube.

[0031] 3. Add 1.5 mL of dioxane, 1.5 mL of mesitylene and 0.6 mL of 6M acetic acid aqueous solution into the above centrifuge tube.

[0032] 4. Sonicate the above-mentioned centrifuge tube for 15 minutes to mix the components in it evenly.

[0033] 5. Seal the mixed solution obtained in step 4 under vacuum.

[0034] 6. Place the sealed ampoule in step 5 in a gas phase furnace at 100°C for 72 hours.

[0035] 7. Wash the material with anhydrous THF and ethanol to remove the reaction solvent and small molecular oligomers.

[0036] 8. Take 10 mg of the COF material obtained in step 7 and add it to a series of 50 mL Erlenmeyer flasks, add 10 mL of heavy metal ion solution (Cu 2+ ,Hg 2+ ,Pb 2+ ,Cr 2+ ,Cd 2+ ), the concentration of each heavy metal ion is 6mmol / L, after adding the COF material, shake at room temperature for 20h....

Embodiment 2

[0039] 1. Add 53mg of oxalodihydrazide to a 5mL ampoule.

[0040] 2. Add 63 mg of 1,3,5-trialdehyde phloroglucinol to the above centrifuge tube.

[0041] 3. Add 1.5mL of o-dichlorobenzene, 1.5mL of N,N-dimethylacetamide and 0.6mL of 6M aqueous acetic acid to the above centrifuge tube.

[0042] 4. Sonicate the above-mentioned centrifuge tube for 15 minutes to mix the components in it evenly.

[0043] 5. Seal the mixed solution obtained in step 4 under vacuum.

[0044] 6. Place the sealed ampoule in step 5 in a gas phase furnace at 100°C for 72 hours.

[0045] 7. Wash the material with anhydrous THF and ethanol to remove the reaction solvent and small molecular oligomers.

[0046] 8. XRD characterization test is to verify that the two monomers do not form a better covalent organic framework structure under the solvent system. Therefore, this solvent system is not suitable for the preparation of COFs with this crystal-ordered structure.

[0047] 9. Take 10 mg of the COF mate...

Embodiment 3

[0049] 1. Add 53mg of oxalodihydrazide to a 5mL ampoule.

[0050] 2. Add 63 mg of 1,3,5-trialdehyde phloroglucinol to the above centrifuge tube.

[0051] 3. Add 3mL of dioxane and 0.6mL of 6M acetic acid aqueous solution to the centrifuge tube.

[0052] 4. Sonicate the above-mentioned centrifuge tube for 15 minutes to mix the components in it evenly.

[0053] 5. Seal the mixed solution obtained in step 4 under vacuum.

[0054] 6. Place the sealed ampoule in step 5 in a gas phase furnace at 100°C for 72 hours.

[0055] 7. Wash the material with anhydrous THF and ethanol to remove the reaction solvent and small molecular oligomers.

[0056] 8. XRD characterization test is to verify that the two monomers do not form a better covalent organic framework structure under the solvent system. Therefore, this solvent system is not suitable for the preparation of COFs with this crystal-ordered structure.

[0057] 9. Take 10 mg of the COF material obtained in step 7 and add it to a s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com