Well drilling high strength pressure-bearing plugging agent and application thereof

A high-strength, plugging agent technology, applied in the direction of drilling compositions, chemical instruments and methods, etc., can solve the problems of easy softening of nutshell materials, affecting the effect of pressure-bearing plugging, and damage to the plugging layer. Achieve the effects of improving the ability to resist bottom hole pressure fluctuations, good toughness, and improving the pressure bearing capacity of the formation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

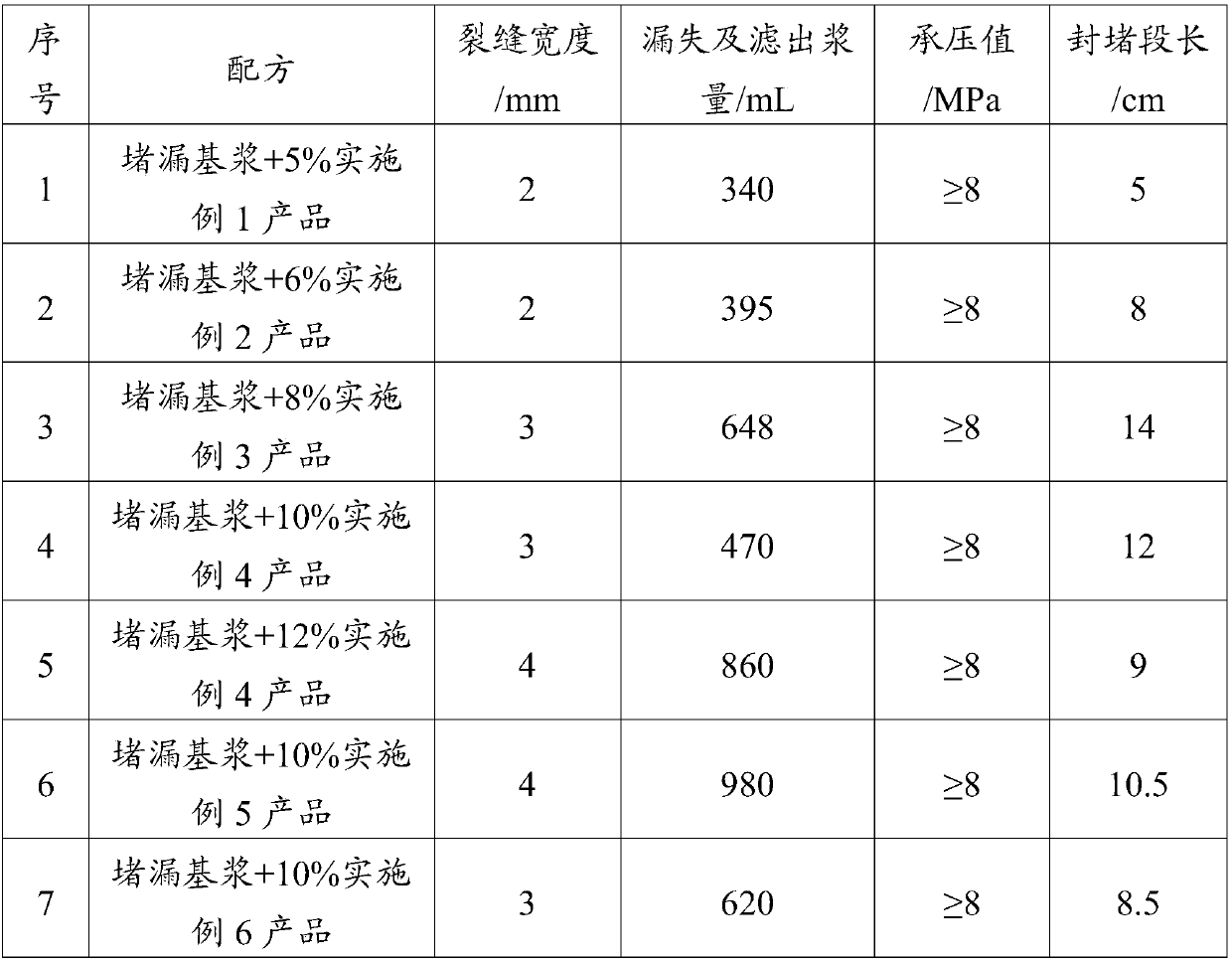

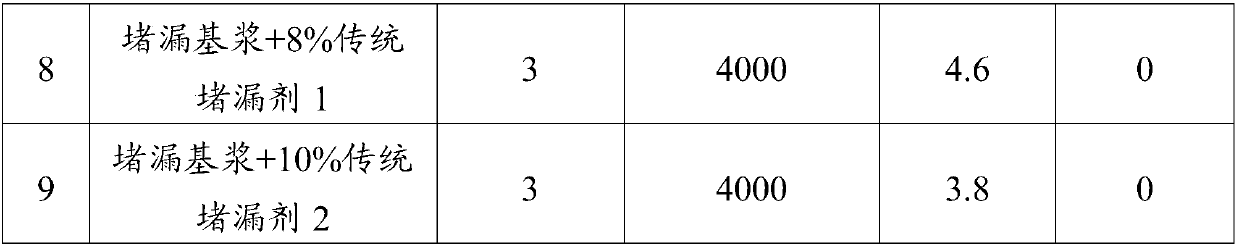

Examples

Embodiment 1

[0050] Weigh 13.8 parts of standard sampling sieve 14-20 mesh PPS plastic granules, standard sampling sieve 40-80 mesh PPS plastic particles 9.2 parts, standard sampling sieve 40-80 mesh expanded graphite particles 30 parts, standard sampling sieve 120- 45 parts of 325-mesh calcium carbonate powder and 3 parts of polypropylene fiber with a length of 3 mm were placed in a mixing device and stirred evenly to obtain the high-strength pressure-bearing plugging agent.

Embodiment 2

[0052] Weigh 15.6 parts of standard sampling sieve 14-20 mesh PPS plastic granules, standard sampling sieve 40-80 mesh PPS plastic particles 10.4 parts, standard sampling sieve 40-80 mesh expanded graphite particles 24 parts, standard sampling sieve 120- 45 parts of 325-mesh quartz sand powder and 3 parts of sepiolite fiber with a length of 5 mm were placed in a mixing device and stirred evenly to obtain the high-strength pressure-bearing plugging agent.

Embodiment 3

[0054] Weigh 16.8 parts of glass fiber reinforced PPS plastic particles of standard sampling sieve 14-20 mesh, 11.2 parts of glass fiber reinforced PPS plastic particles of standard sampling sieve 40-80 mesh, 26 parts of natural graphite particles of standard sampling sieve 40-80 mesh, Put 45 parts of bluestone powder with 120-325 mesh of standard sampling sieve and 6 parts of polypropylene fiber with a length of 3 mm, place them in a mixing device and mix them evenly to obtain the high-strength pressure-bearing plugging agent.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com