Photoetching machine control system and method

A technology of control system and lithography machine, which is applied in the field of lithography machines, can solve the problems of unable to meet the data transmission requirements of high-end lithography machines, the increase of data transmission bandwidth, and the sensor’s susceptibility to electromagnetic interference, etc., so as to avoid complex Effects of program design, increased bandwidth, increased reliability and transfer speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

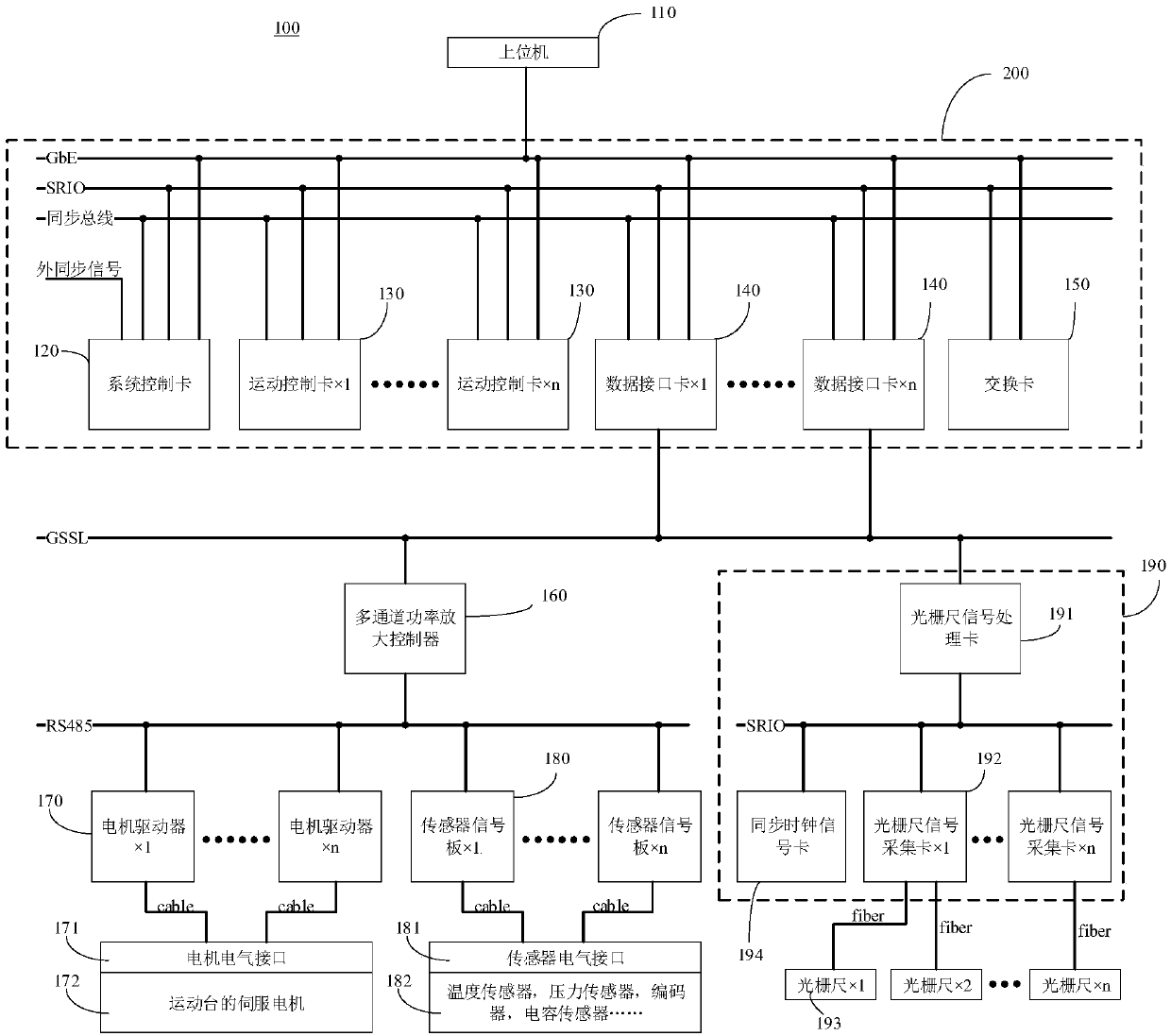

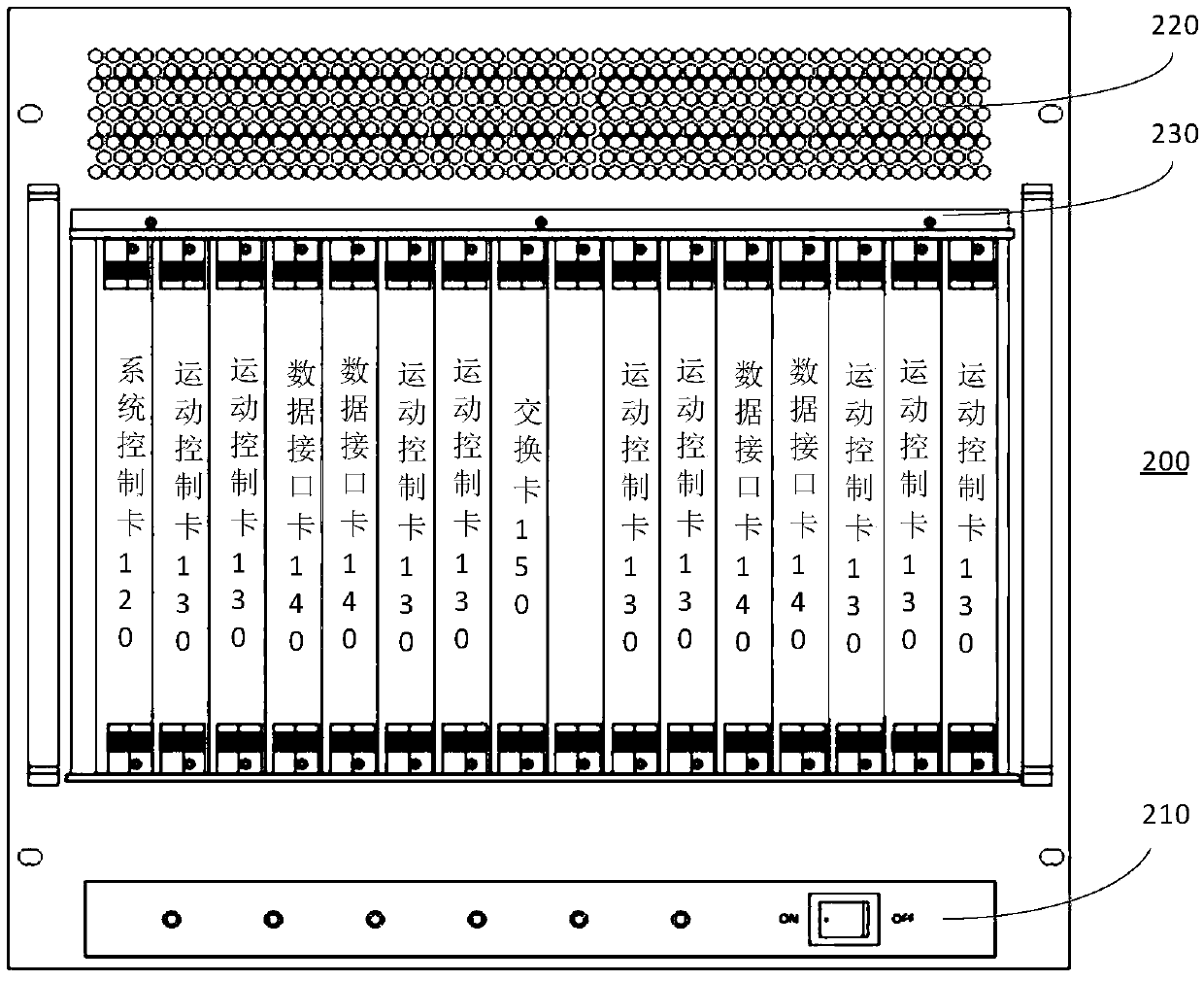

[0045] Please refer to figure 1 , Embodiment 1 of the present invention provides a lithography machine control system 100, including a host computer 110 system control card 120, a motion control card 130, a data interface card 140, an exchange card 150, a multi-channel power amplifier controller 160, and a motor driver 170 , a sensor signal board 180 and a position measurement unit 190 .

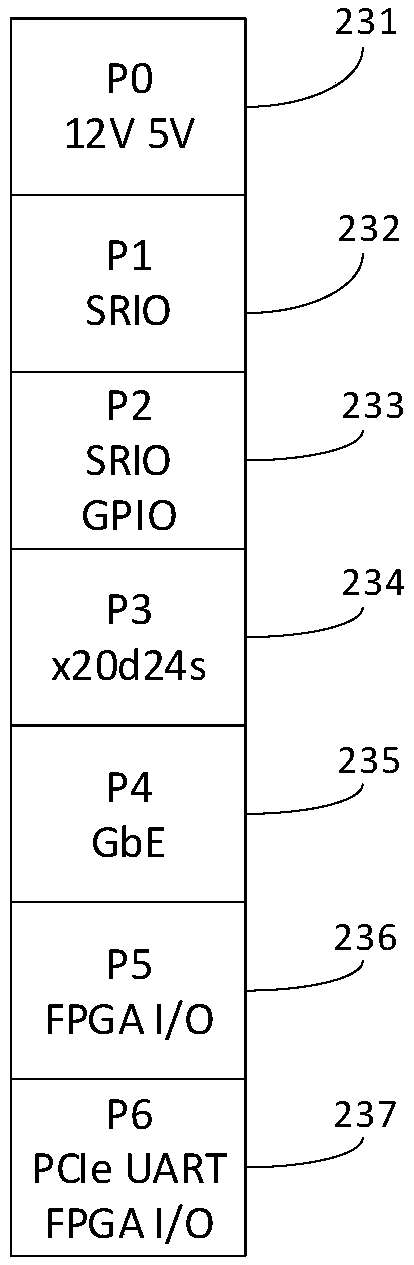

[0046] Among them, the system control card 120, the motion control card 130, the data interface card 140 and the switch card 150 are connected through the VPX bus (SRIO) for data transmission.

[0047] Wherein, the system control card 120 , the motion control card 130 , the data interface card 140 and the switch card 150 are connected to the host computer 110 through Ethernet (GbE) for command processing.

[0048] Wherein, the system control card 120, the motion control card 130 and the data interface card 140 are connected with a synchronization bus, which is used to synchronize the clock ...

Embodiment 2

[0098] Please refer to Figure 6 , the lithography machine control system provided in the second embodiment of the present invention is improved on the basis of the first embodiment, the difference lies in the connection mode of the sensor signal board 180 . That is, the input end of the sensor signal board 180 in Embodiment 2 of the present invention is connected to various sensors, and the output end of the sensor signal board 180 is directly connected to the data interface card 140 through an optical fiber or other wires; that is, the sensor signal board 180 can be It is directly connected to the data interface card 140 through the optical fiber interface instead of the power amplification controller 160 . The sensor signal board 180 directly sends the underlying sensor data to the data interface card 140 through the GSSL protocol, and the data interface card 140 parses the data format of the GSSL protocol into the data format of the SRIO protocol, and then forwards it to t...

Embodiment 3

[0102] Please refer to Figure 7 , the lithography machine control system provided in the third embodiment of the present invention is improved on the basis of the first embodiment, the difference lies in the connection mode of the sensor signal board 180 . In Embodiment 3 of the present invention, the input end of the sensor signal board 180 is connected to the sensor, and the output end of the sensor signal board 180 is connected to the motion control card 130 by optical fibers or other wires through a channel of the multi-channel power amplifier controller 160 . That is, in the third embodiment of the present invention, on the basis of the first embodiment, the data interface card 140 is removed, and the power amplifier controller 160 and the motion control card 130 are directly connected through an optical fiber. Compared with Embodiment 1 and Embodiment 2, this embodiment omits the data interface card 140 , but uses the optical fiber interface of the motion control card 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com