Low-melting-point high-flowability ternary random copolymer polyamide modified base material resin and preparation method thereof

A random copolymerization and base resin technology, which is applied in the field of ternary random copolymer polyamide modified base resin and its preparation, can solve the problems of decomposition, deterioration, and inability to add, so as to improve fluidity and reduce regularity , the effect of less decomposition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

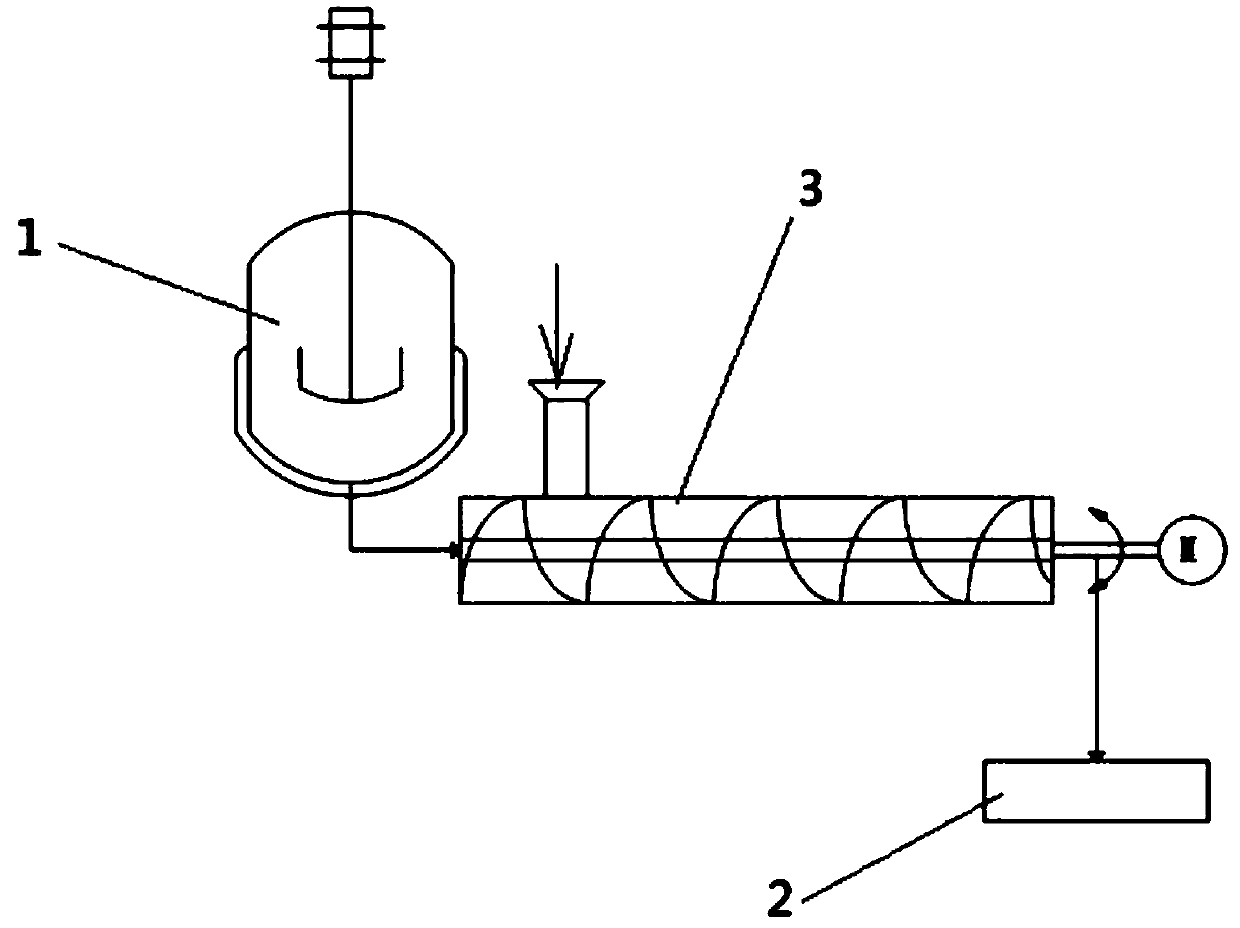

Image

Examples

Embodiment 1

[0032] 37.7kg (324mol) of hexamethylenediamine and 47.3kg (324mol) of adipic acid were mixed and reacted in desalted water at 60°C to form a salt, and a small amount of hexamethylenediamine was added to adjust the pH, so that the weight concentration was 53%, and the pH was 7.8. Polyamide salt solution;

[0033] 4.4kg (38mol) of 2-methylpentamethylenediamine and 5.6kg (38mol) of adipic acid were mixed and reacted in desalted water at 60°C to form a salt, and a small amount of hexamethylenediamine was added to adjust the pH to obtain a weight concentration of 53%, A polyamide salt solution with a pH of 7.8;

[0034] 5 kg (44 mol) of caprolactam was dissolved in desalted water at 60°C to obtain a caprolactam solution with a weight concentration of 50%. Mix the three solutions evenly, pour them into a concentration tank, and under the protection of nitrogen at an absolute pressure of 0.2MPa (absolute pressure), slowly heat and evaporate to concentrate until the concentration of ...

Embodiment 2

[0039] 34.6kg (298mol) of hexamethylenediamine and 43.4kg (298mol) of adipic acid were mixed and reacted in desalted water at 65°C to form a salt, and a small amount of hexamethylenediamine was added to adjust the pH, so that the weight concentration was 60%, and the pH was 7.5. Polyamide salt solution;

[0040] Mix 6.6 kg (57.5 mol) of 2-methylpentamethylenediamine and 8.4 kg (57.5 mol) of adipic acid in desalted water at 65°C to form a salt, and add a small amount of hexamethylenediamine to adjust the pH to obtain a weight concentration of 60 %, pH is the polyamide salt solution of 7.5;

[0041] 7 kg (62 mol) of caprolactam was dissolved in desalted water at 65°C to obtain a caprolactam solution with a weight concentration of 60%.

[0042]Mix the three solutions evenly, pour them into a concentration tank, and under the protection of nitrogen at an absolute pressure of 0.25MPa (absolute pressure), slowly heat and evaporate to concentrate until the concentration of the polya...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fluidity | aaaaa | aaaaa |

| Fluidity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com