Culture medium for blood culture bottle production and blood culture bottle production process

A production process and blood culture technology, which is applied in the field of medical chemiluminescence immunoassay detection, can solve problems such as unstable results, no blood culture bottles, and low detection rate of blood culture bottles, achieving high detection rate and stable results Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

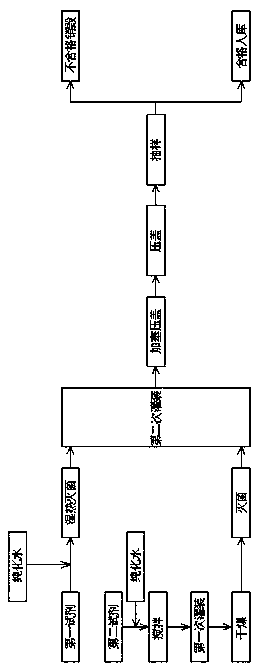

Image

Examples

Embodiment 1

[0033] A production process for a blood culture bottle, comprising preparation of a first reagent, preparation of a second reagent and filling into a bottle, wherein the preparation of the first reagent comprises the following steps:

[0034] S1, dosing, take an appropriate amount of the first reagent, add purified water therein, wherein calculated in parts by weight, silica gel RT601A is 800 parts, silica gel RT601B is 50 parts, and sodium hydroxide is a sodium hydroxide solution with a concentration of 1mol / L. The addition amount is 2 parts, and the addition amount of purified water is 20 parts to obtain a silica gel mixture;

[0035] S2, stirring, stirring the silica gel mixture evenly;

[0036] S3, filling for the first time, filling the well-stirred silica gel mixture to the bottom with CO 2 Sensors and selectively permeable CO 2 membrane culture flask;

[0037] S4, drying, heating the culture bottle for 10 hours in an environment of 45° C., so that the silica gel mixt...

Embodiment 2

[0049] A production process for a blood culture bottle, comprising preparation of a first reagent, preparation of a second reagent and filling into a bottle, wherein the preparation of the first reagent comprises the following steps:

[0050] S1, dosing, take an appropriate amount of the first reagent, add purified water therein, wherein calculated by weight, silica gel RT601A is 1000 parts, silica gel RT601B is 150 parts, sodium hydroxide is a sodium hydroxide solution with a concentration of 1mol / L, The addition amount is 4 parts, and the addition amount of purified water is 40 parts to obtain a silica gel mixture;

[0051] S2, stirring, stirring the silica gel mixture evenly;

[0052] S3, filling for the first time, filling the well-stirred silica gel mixture to the bottom with CO 2 Sensors and selectively permeable CO 2 membrane culture flask;

[0053] S4, drying, heating the culture bottle for 10 hours in an environment of 45° C., so that the silica gel mixture at the ...

Embodiment 3

[0064] A production process for a blood culture bottle, comprising preparation of a first reagent, preparation of a second reagent and filling into a bottle, wherein the preparation of the first reagent comprises the following steps:

[0065] S1, dosing, take an appropriate amount of the first reagent, add purified water to it, wherein calculated in parts by weight, silica gel RT601A is 900 parts, silica gel RT601B is 100 parts, and sodium hydroxide is a sodium hydroxide solution with a concentration of 1mol / L. The addition amount is 3 parts, and the addition amount of purified water is 30 parts to obtain a silica gel mixture;

[0066] S2, stirring, stirring the silica gel mixture evenly;

[0067] S3, filling for the first time, filling the well-stirred silica gel mixture to the bottom with CO 2 Sensors and selectively permeable CO 2 membrane culture flask;

[0068] S4, drying, heating the culture bottle for 10 hours in an environment of 45° C., so that the silica gel mixtu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com