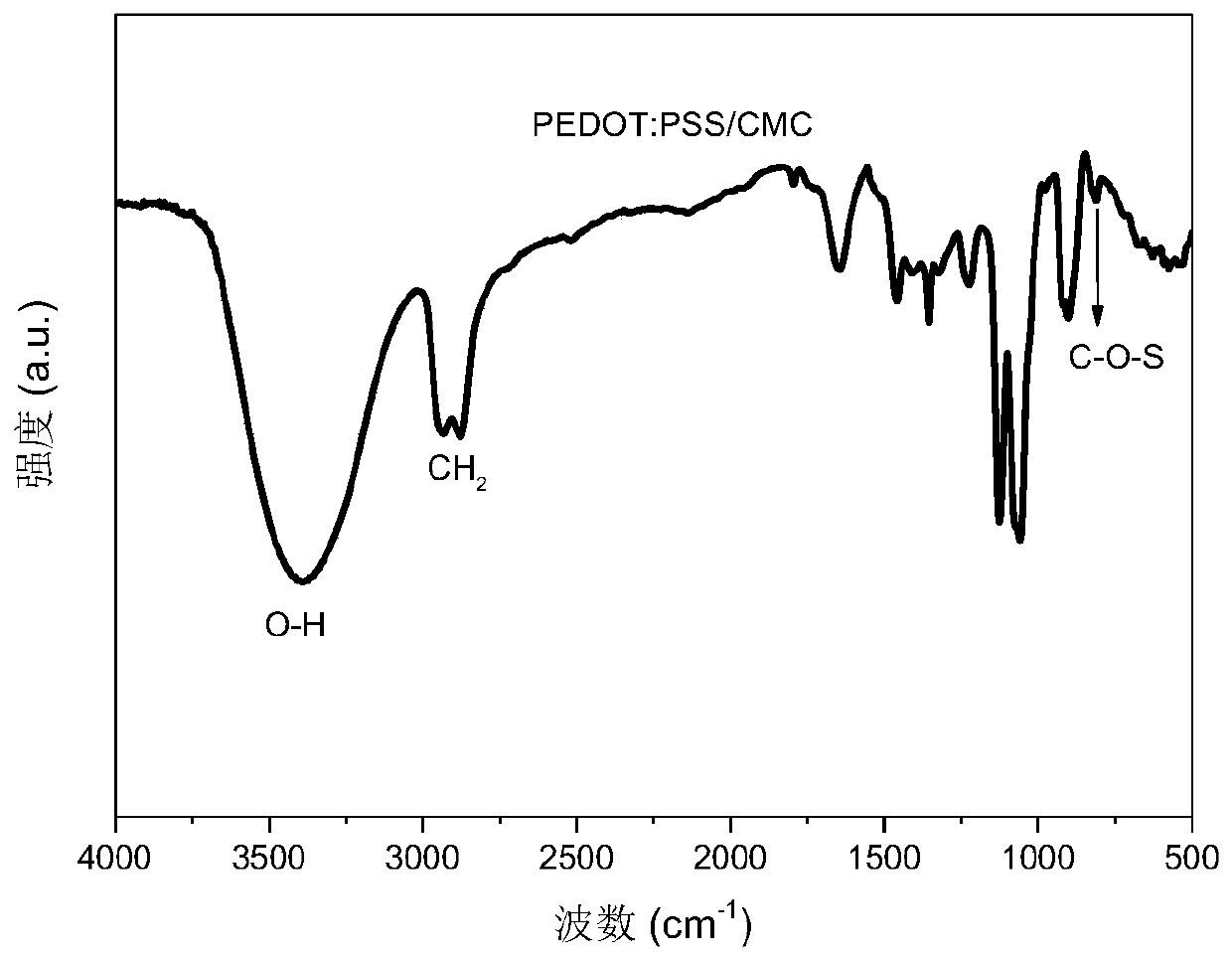

PEDOT: PSS/CMC composite binder and preparation method and application thereof

A binder and solvent technology, applied in the field of PEDOT:PSS/CMC composite binder and its preparation, can solve the problems of consumption of active lithium, reduction of capacity retention rate and Coulomb efficiency, difficulty in improving space, etc. Performance and conductivity, avoid electrode structure instability, improve the effect of structural stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] (1) Use an electronic balance to weigh 1g of PEDOT:PSS powder and 1g of CMC powder, and dissolve PEDOT:PSS powder and CMC powder in 50mL deionized water to prepare PEDOT:PSS solution and CMC with a mass percentage of 2wt%. solution. Solution preparation conditions: Stir at 25° C. for 4 h, with a stirring rate of 400 rpm.

[0055] (2) Mix the two solutions in step (1) at a volume ratio of 1:1, stir at 25°C for 12 hours, and the stirring rate is 400rpm, and prepare a PEDOT:PSS / CMC composite bond with a concentration of 2wt%. agent;

[0056] (3) Mix the silicon-based material with the PEDOT:PSS / CMC composite binder at a mass ratio of 8:2 (the ratio of the mass of the silicon-based material to the solute in the binder), grind evenly, and adjust the viscosity with deionized water, Obtain negative electrode slurry. Use a scraper to evenly coat the negative electrode slurry on the copper foil, dry it under vacuum at 80°C, cut into pieces, and roll press to obtain a silicon-...

Embodiment 2

[0062] (1) Use an electronic balance to weigh 1g of PEDOT:PSS powder and 1g of CMC powder, and dissolve PEDOT:PSS powder and CMC powder in 50mL deionized water to prepare PEDOT:PSS solution and CMC with a mass percentage of 2wt%. solution. Solution preparation conditions: Stir at 25° C. for 4 h, with a stirring rate of 400 rpm.

[0063] (2) Mix the two solutions in step (1) at a volume ratio of 2:1, stir at 25°C for 12 hours, and the stirring rate is 400rpm, and prepare a PEDOT:PSS / CMC composite bond with a concentration of 2wt%. agent;

[0064] (3) Mix the silicon-based material with the above-mentioned PEDOT:PSS / CMC composite binder at a mass ratio of 8:2 (the ratio of the mass of the silicon-based material to the solute in the binder material), grind evenly, and adjust with deionized water Viscosity, obtain negative electrode slurry. Use a scraper to evenly coat the negative electrode slurry on the copper foil, dry it under vacuum at 80°C, cut into pieces, and roll press...

Embodiment 3

[0068] (1) Use an electronic balance to weigh 1g of PEDOT:PSS powder and 1g of CMC powder, and dissolve PEDOT:PSS powder and CMC powder in 50mL deionized water to prepare PEDOT:PSS solution and CMC with a mass percentage of 2wt%. solution. Solution preparation conditions: Stir at 25° C. for 4 h, with a stirring rate of 400 rpm.

[0069] (2) Mix the two solutions in step (1) at a volume ratio of 5:1, stir at 25°C for 12 hours, and the stirring rate is 400rpm, and prepare a PEDOT:PSS / CMC composite bond with a concentration of 2wt%. agent;

[0070] (3) Mix the silicon-based material with the above-mentioned PEDOT:PSS / CMC composite binder at a mass ratio of 8:2 (the ratio of the mass of the silicon-based material to the solute in the binder material), grind evenly, and adjust with deionized water Viscosity, obtain negative electrode slurry. Use a scraper to evenly coat the negative electrode slurry on the copper foil, dry it under vacuum at 80°C, cut into pieces, and roll press...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Discharge specific capacity | aaaaa | aaaaa |

| Discharge specific capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com