A method for arc additive manufacturing of multi-material monolithic structural parts

A technology of integral structural parts and additive manufacturing, which is applied in the direction of manufacturing tools, additive processing, arc welding equipment, etc., can solve the problems of low forming efficiency, surface defects, poor forming accuracy of integral structural parts, etc., to meet the forming requirements, Effect of improving molding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

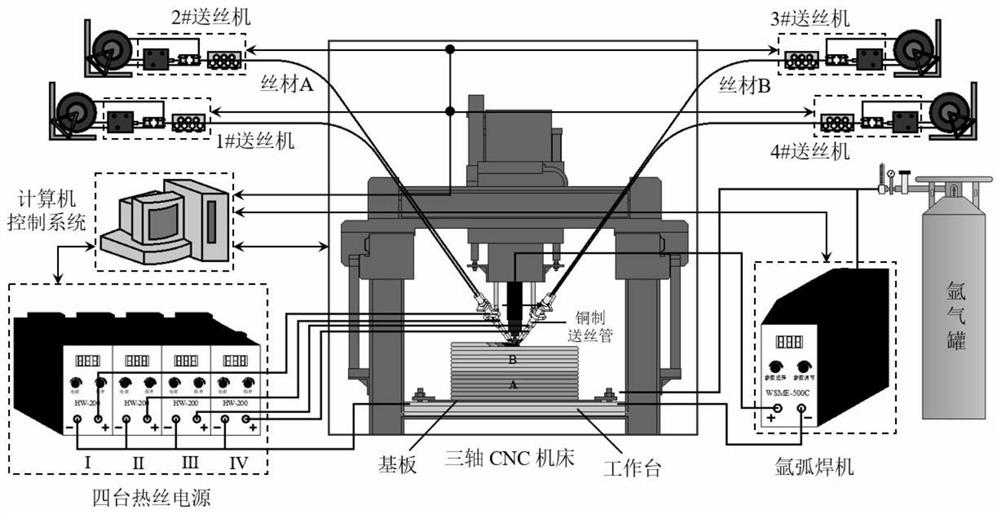

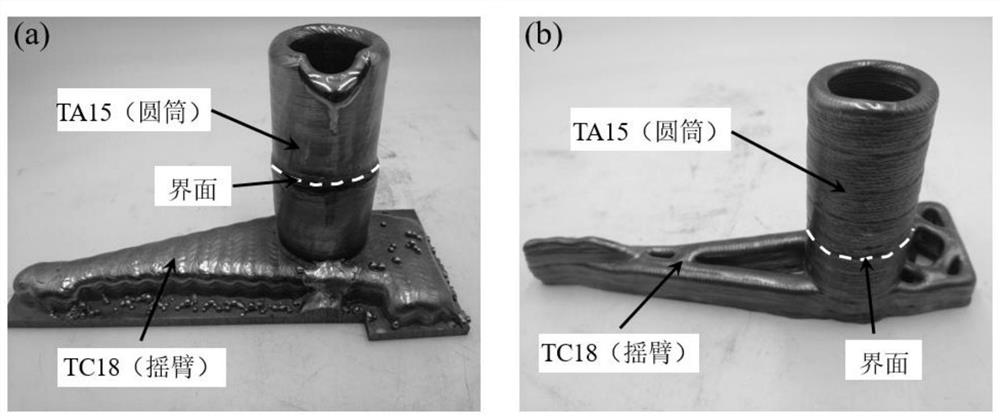

[0044] use figure 1 The device shown is used to prepare the breech breech barrel, in which the material of the cylindrical part (ie, the rigid connection part) is TA15 titanium alloy, and the material of the rocker arm part (ie, the loading area) is TC18 titanium alloy. The specific steps are as follows:

[0045]Build a three-dimensional solid model through solidworks software, then use 3D data processing software for slicing processing, then generate a processing program, and import the processing program into the control system; install two TC18 titanium alloy wires with a diameter of 1.6mm on the 1# wire feeder and 2# wire feeder, install two TA15 titanium alloy wires with a diameter of 1.6mm on 3# wire feeder and 4# wire feeder, and install the hot wire power supplies numbered Ⅰ, Ⅱ, Ⅲ, and Ⅳ The positive pole is connected to the wire on 1# wire feeder, 2# wire feeder, 3# wire feeder and 4# wire feeder in turn through copper wire feeder tube, the distance between the connec...

Embodiment 2

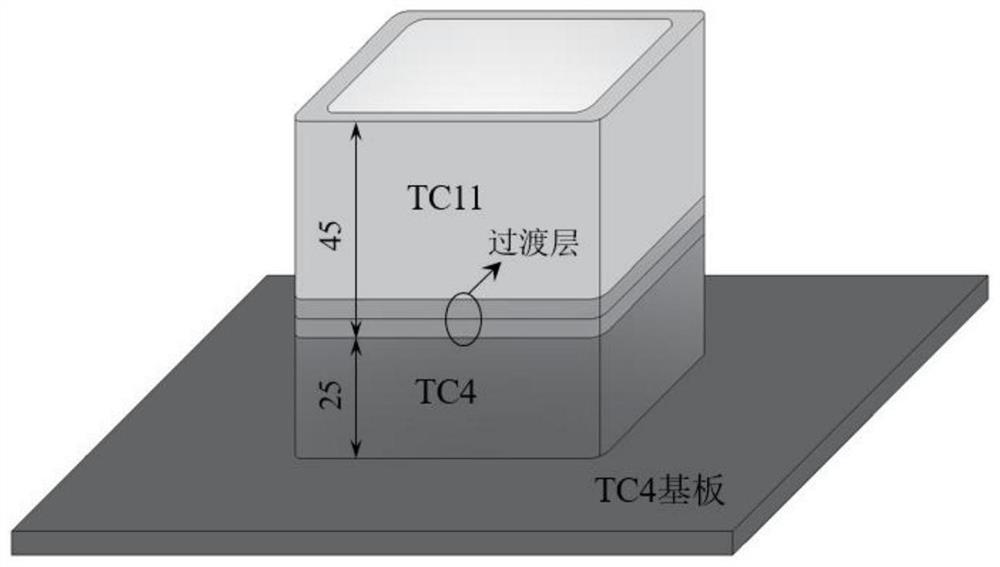

[0055] use figure 1 The shown device prepares TC4-TC11 titanium alloy thin-walled devices, wherein the lower layer is made of TC4 titanium alloy with a height of 25 mm, and the upper layer is made of TC11 titanium alloy with a height of 45 mm. The specific steps are as follows:

[0056] Build a 3D solid model through solidworks software (such as image 3 shown), and then use 3D data processing software for slicing processing, the layer height is 2.5mm, then generate a processing program, and import the processing program into the control system;

[0057] Install two TC4 titanium alloy wires with a diameter of 1.6mm on 1# wire feeder and 2# wire feeder, install two TC11 titanium alloy wires with a diameter of 1.6mm on 3# wire feeder and 4# On the wire feeder, pass the positive poles of the hot wire power supplies numbered Ⅰ, Ⅱ, Ⅲ, and Ⅳ through the wires on 1# wire feeder, 2# wire feeder, 3# wire feeder and 4# wire feeder in turn. The copper wire feeding tube is connected, th...

Embodiment 3

[0061] use figure 1 The device shown prepares TC4-TC11 titanium alloy gradient block, wherein the lower layer is made of TC4 titanium alloy with a height of 35 mm, and the upper layer is made of TC11 titanium alloy with a height of 35 mm. The specific steps are as follows:

[0062] Build a 3D solid model through solidworks software (such as Figure 5 shown), and then use 3D data processing software for slicing processing, the layer height is 3.5mm, then generate a processing program, and import the processing program into the control system;

[0063] Install two TC4 titanium alloy wires with a diameter of 1.6mm on 1# wire feeder and 2# wire feeder, install two TC11 titanium alloy wires with a diameter of 1.6mm on 3# wire feeder and 4# On the wire feeder, pass the positive poles of the hot wire power supplies numbered Ⅰ, Ⅱ, Ⅲ, and Ⅳ through the wires on 1# wire feeder, 2# wire feeder, 3# wire feeder and 4# wire feeder in turn. The copper wire feeding tube is connected, the di...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| current | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com