Heat insulation board production line

A technology of thermal insulation board and production line, applied in the field of machinery, can solve the problems of labor-consuming, easy deformation of thermal insulation board, cumbersome process, etc., to achieve the effect of solving board deformation, overcoming the inability to use metal conveyor belts, and overcoming technical difficulties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

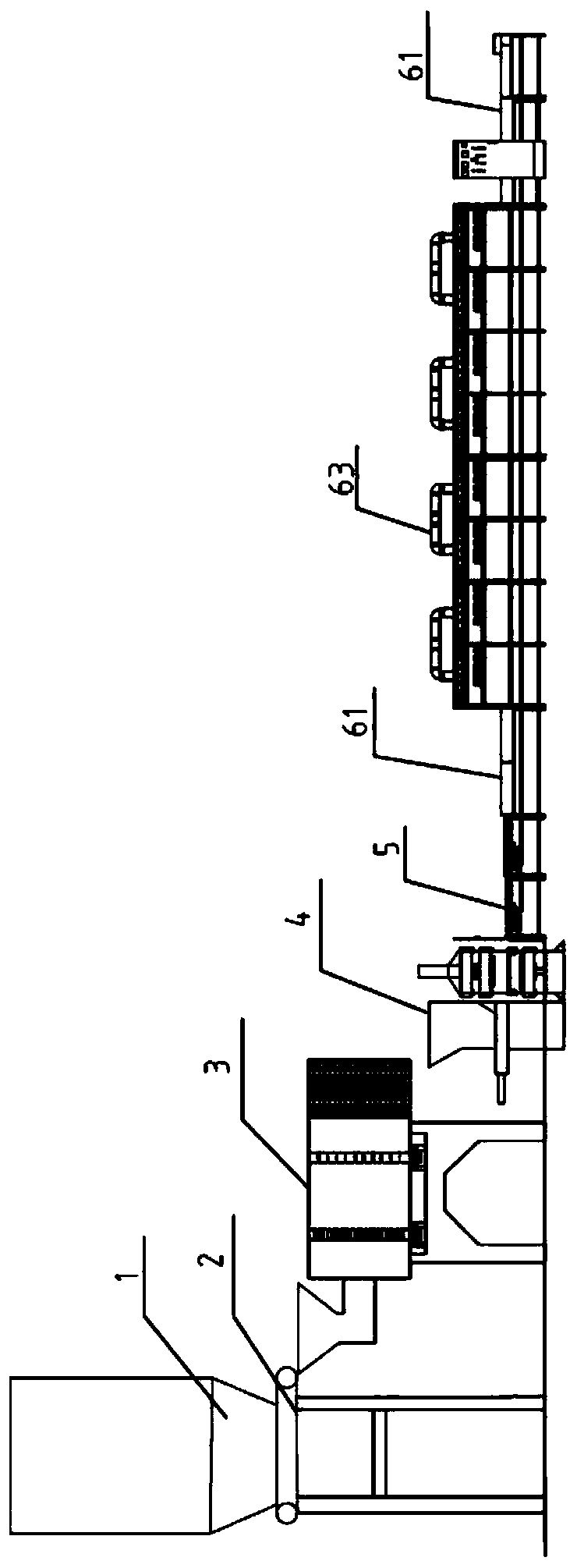

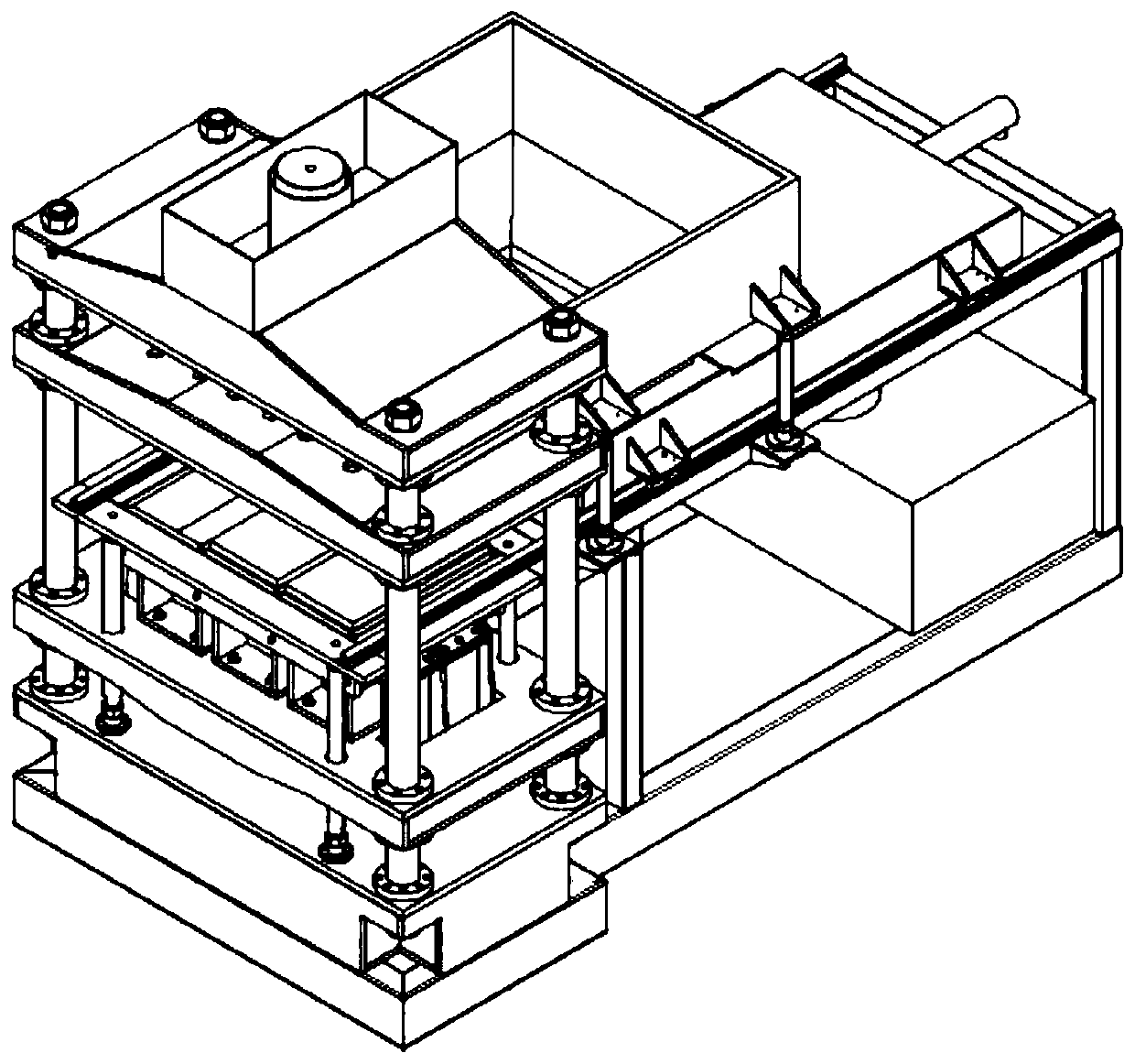

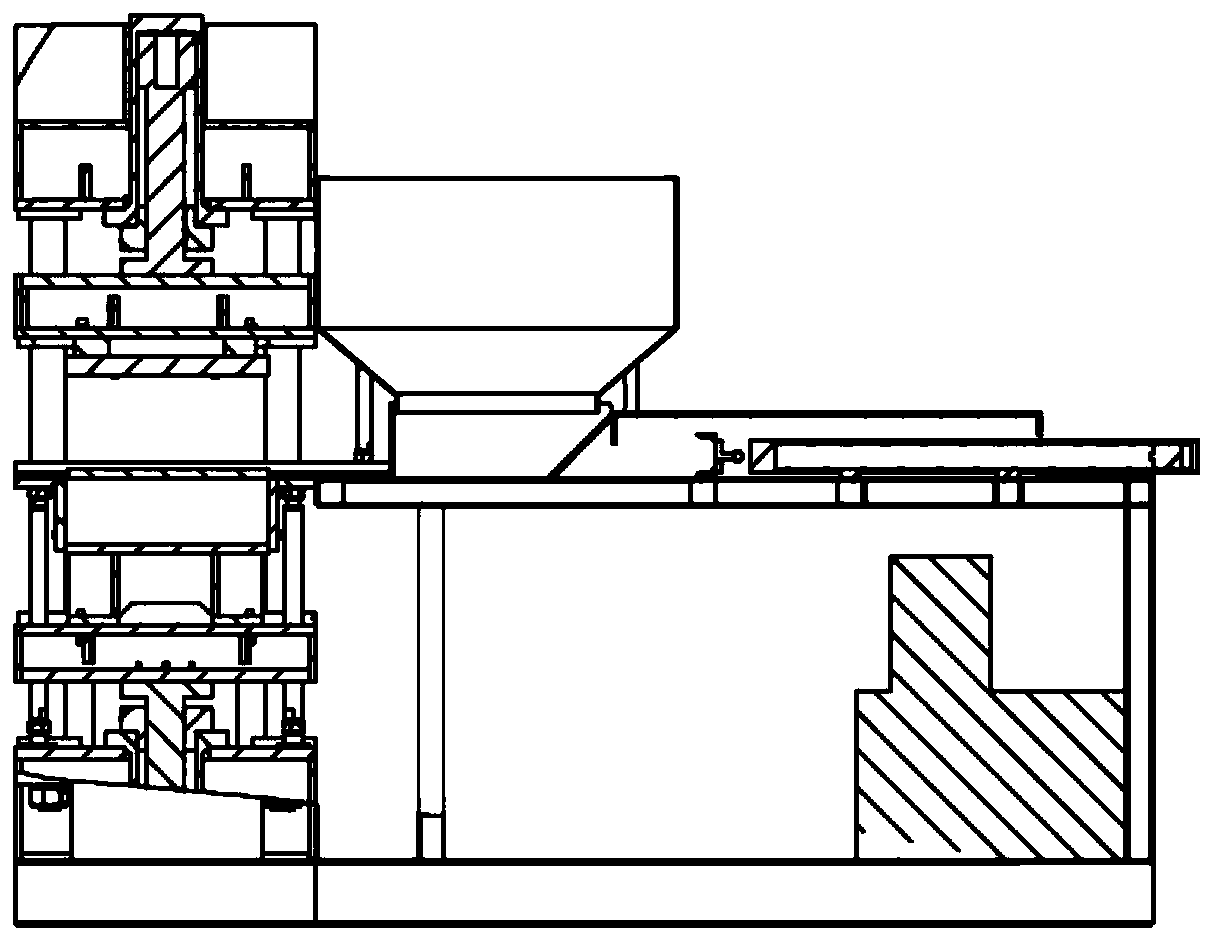

[0012] Such as figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 As shown, a thermal insulation board production line includes a storage bin, a distributor 1, a screw feeder 2, a mixer 3, a glue storage tank, a plate press 4, a conveyor 5, a microwave dryer 6, a packaging machine, and a distributor 1 is set at the lower end of the storage bin, the distributor 1 is provided with a frequency conversion controller, the feeding port of the screw feeder 2 is connected with the discharge port of the storage bin through the distributor 1, the screw feeder 3 The feed inlet is also connected to the glue storage tank through a glue pump, the glue pump is a variable frequency glue pump, controlled by a PID controller, an electromagnetic flowmeter is used to detect the flow of glue stirring, and the outlet of the screw feeder 2 is connected to the mixer 3, the outlet of the mixer 3 is connected to the hopper of the platen machine 4, the outlet of the platen machine 4 is connec...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap