Large-particle solder feeder

A large particle feeder technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of destroying the structure of large particle alloy materials, failing to meet process requirements, intermittent and unstable feeding, etc. , to achieve accurate flow control, expand the scope of use and use occasions, and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

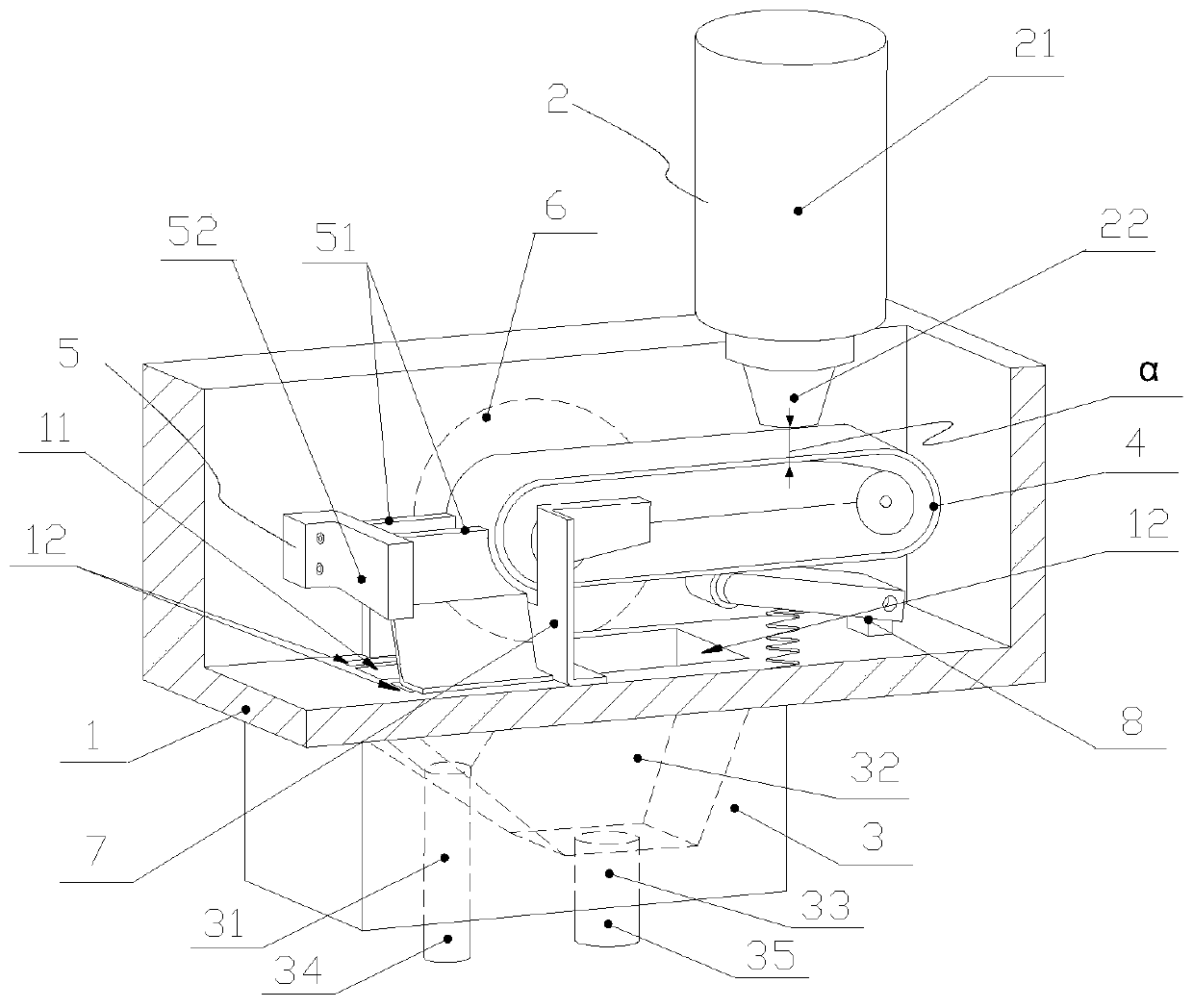

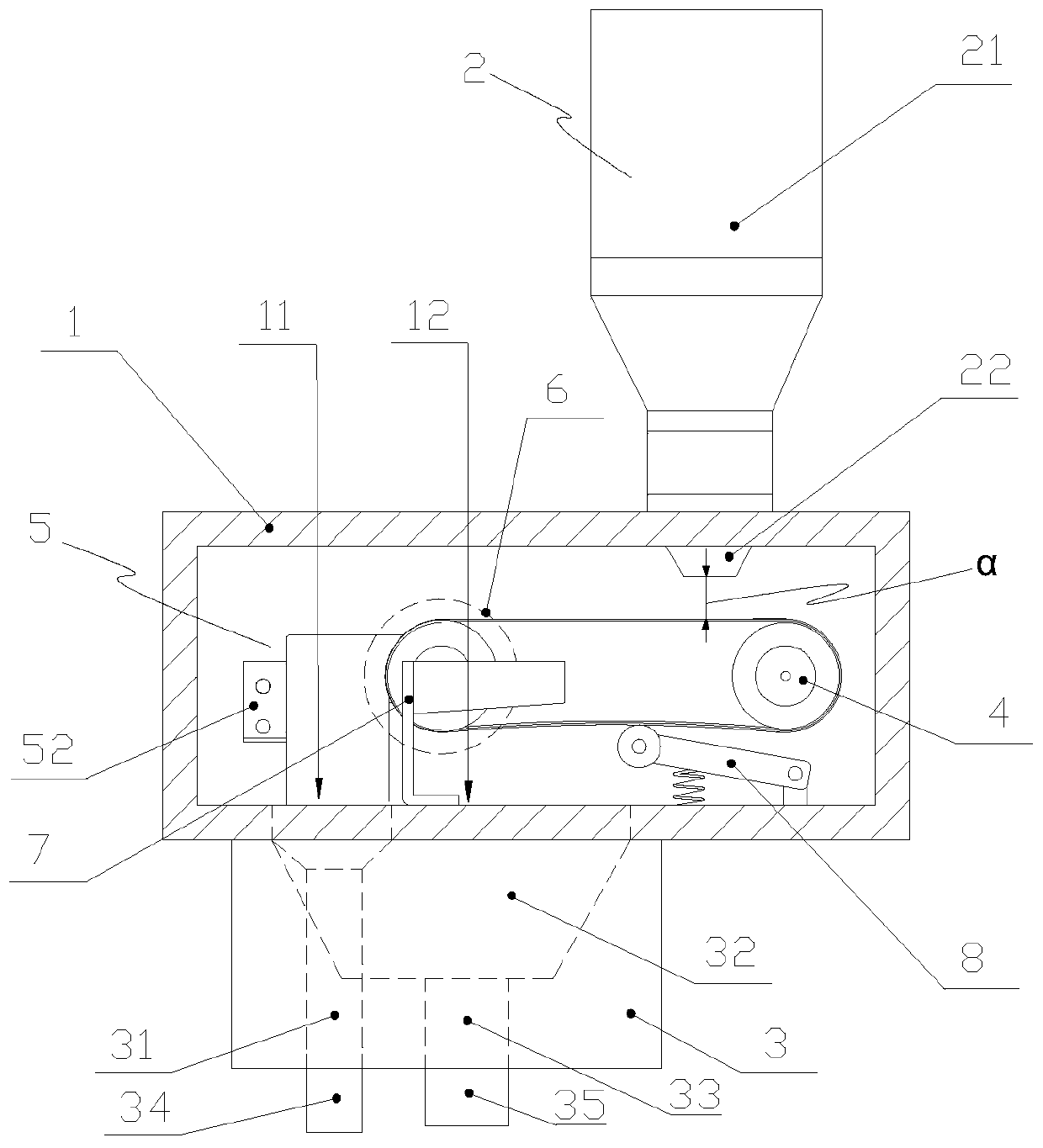

[0060] Such as figure 1 A schematic diagram of a three-dimensional structure of a large-particle solder feeder provided by an embodiment of the present invention, figure 2 A schematic cross-sectional structure diagram of a large-particle solder feeder provided by an embodiment of the present invention, image 3 A schematic diagram of the structure of a large-grain solder feeder provided in an embodiment of the present invention, Figure 4 A schematic diagram of the arrangement of the main material outlet and the auxiliary material outlet inside the shell of a large-particle solder feeder provided by the embodiment of the present invention is shown in the following figure:

[0061] A large particle solder feeder comprising:

[0062] Housing 1, material barrel 2, material chamber housing 3;

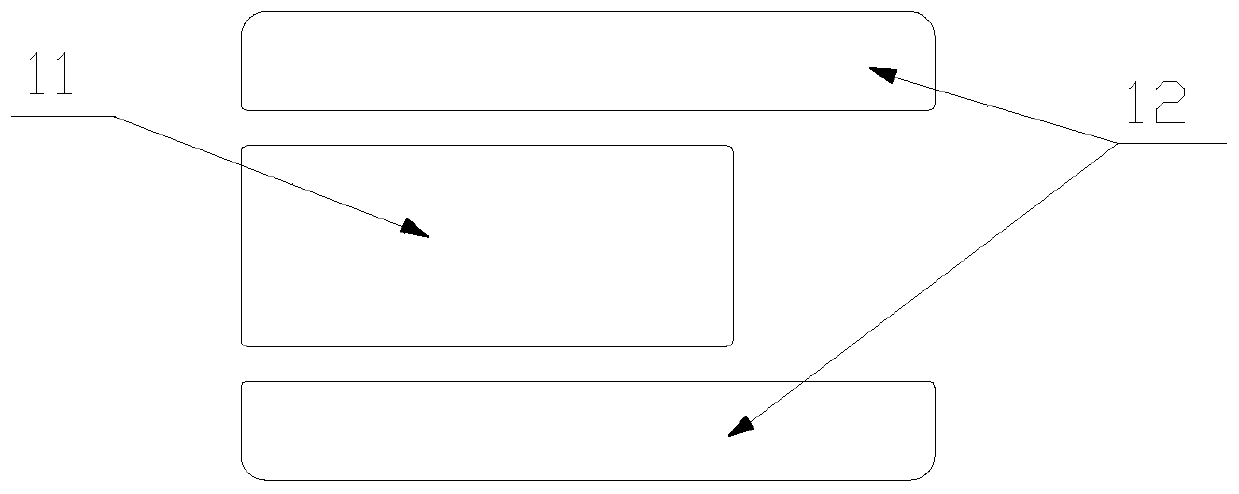

[0063] The inside of the housing 1 is provided with a conveyor belt 4 and a flow regulating mechanism 5, the bottom of the housing 1 is provided with a main material outlet 11 and an au...

Embodiment 2

[0080] This embodiment is an extended implementation of Embodiment 1, aiming at multi-level and further precise control of the flow rate of the large-particle solder.

[0081] In this implementation, the basic structure of the large-particle solder feeder is the same as that shown in Embodiment 1, except that it also includes a second flow regulating mechanism, which is arranged at the bottom or the main flow regulating mechanism 5. Below the material outlet 11.

[0082] The second flow regulating mechanism may include N flow regulating devices 5', where N is a natural number.

[0083] Figure 5 The schematic cross-sectional structure diagram of a large-particle solder feeder connected in series with the second flow regulating mechanism provided by the embodiment of the present invention shows a situation where the second flow regulating mechanism is connected in series below the flow regulating mechanism 5, and the second The scenario that the flow regulating mechanism is a...

Embodiment 3

[0093] This embodiment is based on the above-mentioned embodiment 1 or embodiment 2, and further improves the large-grain solder feeder provided by the embodiment of the present invention, so that it can achieve a better use effect.

[0094] First of all, on the basis of the above-mentioned embodiment 1 or embodiment 2, the present embodiment is provided with a switch mechanism (not shown in the figure) on the material nozzle 22, and the switch mechanism is used to open or close the material nozzle 22, so as to control the large particles Start and end of solder feeder work.

[0095] Preferably, the switch mechanism is a plate gate (not shown in the figure); the plate gate is the simplest switch mechanism, which is easy to manufacture, low in price, and not easy to be blocked.

[0096] Secondly, on the basis of the above-mentioned embodiment 1 and embodiment 2, the opening and closing mechanism (not shown in the figure) is provided at the bottom of the auxiliary material hole ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com