Method and device for treating chemical wastewater with high salt content and high organic matter content

A technology for chemical wastewater and high-salt wastewater, applied in the direction of special compound water treatment, multi-stage water treatment, water/sewage treatment, etc., can solve the problems of small sludge production, high organic matter, difficult treatment, etc., and achieve small sludge production , stable operation and low power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The implementation of the present invention will be illustrated by specific specific examples below, and those skilled in the art can easily understand other advantages and effects of the present invention from the content disclosed in this specification.

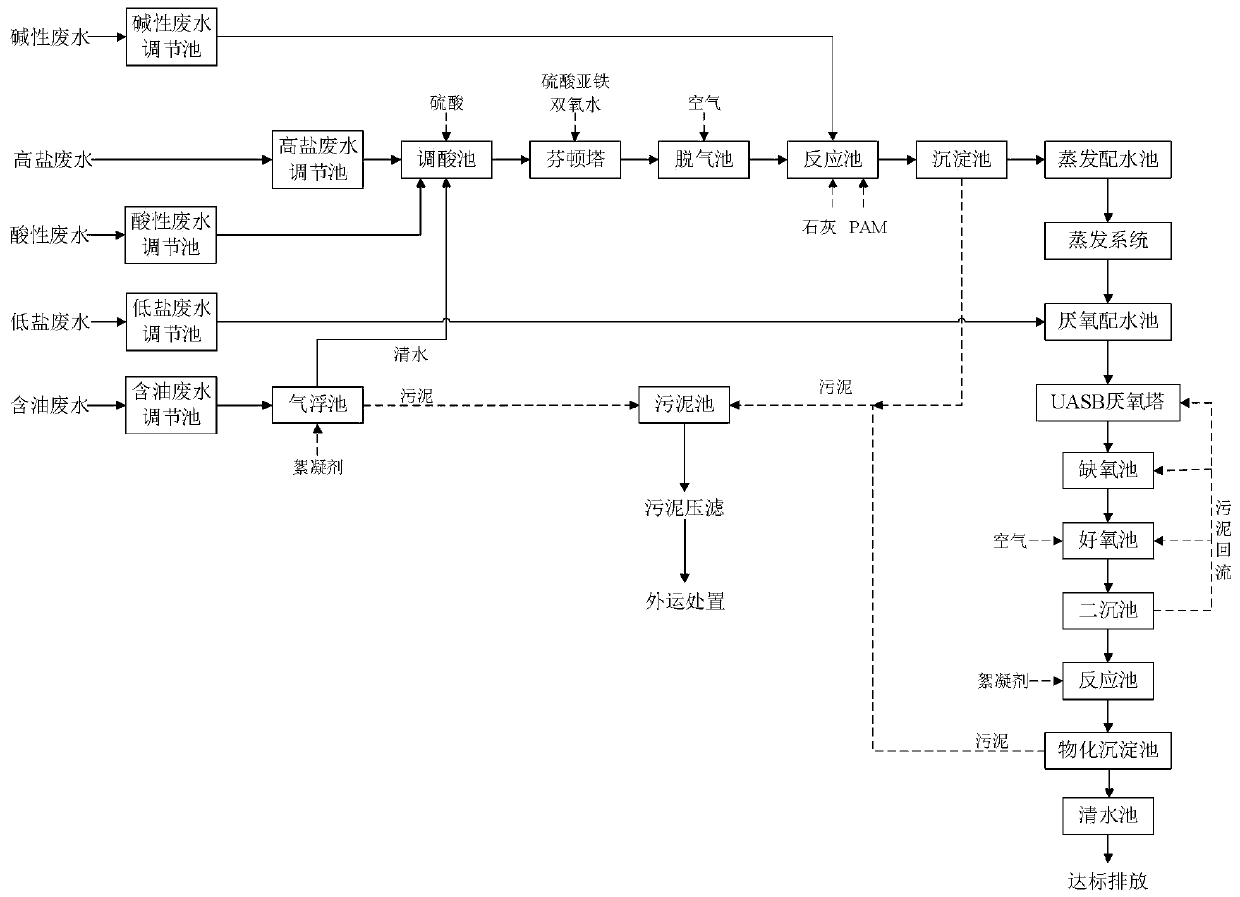

[0025] see figure 1 , is a structural schematic diagram of an embodiment of the present invention, providing a method for treating chemical wastewater with high salt content and high organic matter up to standard. In view of the characteristics of high-salt and high-organic content in chemical wastewater, the process wastewater enters the regulating tank first, and then enters the core system of the method for the standard treatment of high-salt and high-organic chemical wastewater according to the present invention, "Adjustment + Fenton Pretreatment + evaporation + anaerobic + biochemical + physical and chemical"-based process route, and then discharge through the reaction tank and physical and chemical sedimentatio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface load factor | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com