Noctilucent ground wire and processing technology thereof

A processing technology and grounding wire technology, applied in the field of luminous grounding wire and its processing technology, can solve the problems affecting the luminous effect and stability of the grounding wire, and the reunion of luminous materials, so as to improve the luminous effect, prevent reunion, and reduce self-weight.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] A luminous grounding wire includes a grounding wire body, the grounding wire body includes a copper core and an insulating sheath wrapping the copper core, the insulating sheath is wrapped with a fluorescent sheath, and the luminous grounding wire is processed by the following processing steps:

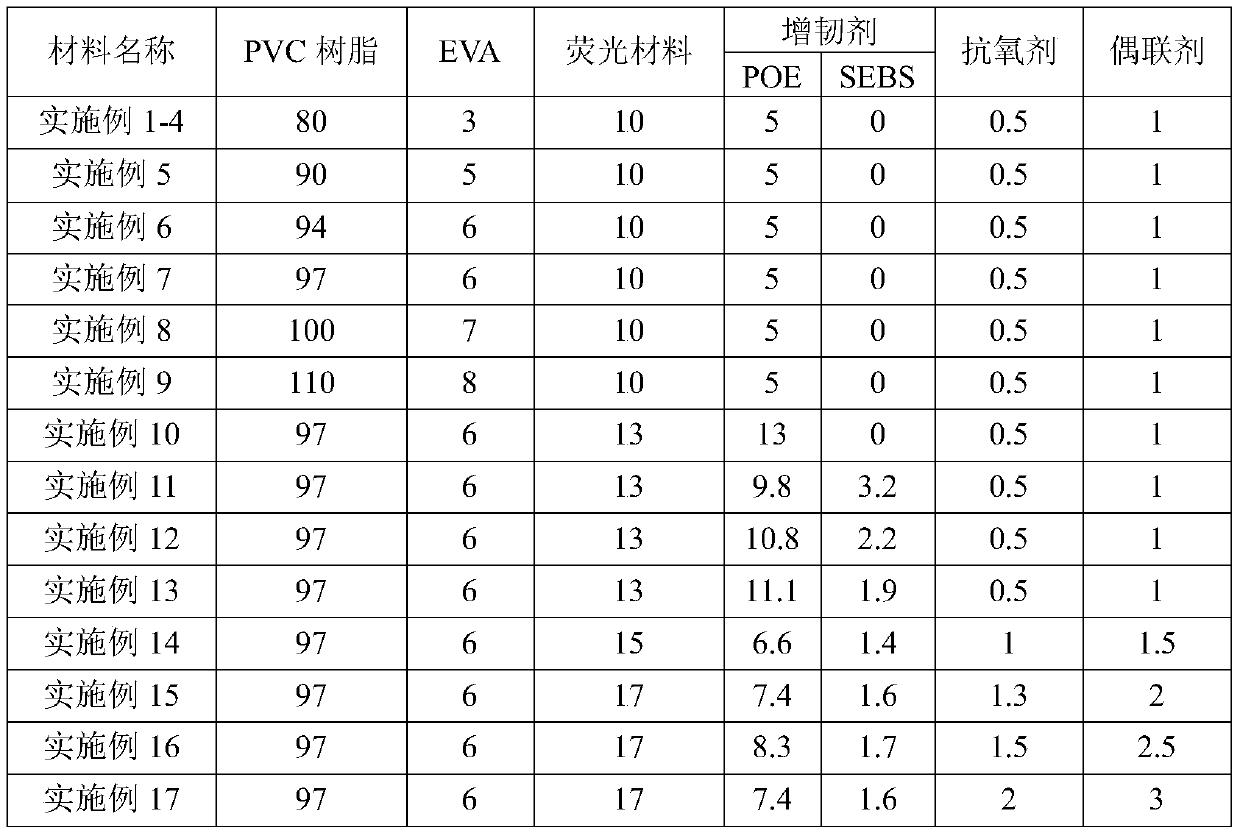

[0040] Preparation of fluorescent sheath material: According to the addition amount in Table 1, add polyvinyl chloride resin, ethylene-vinyl acetate copolymer, toughening agent, antioxidant and coupling agent into the internal mixer and mix for 10 minutes to 150 ℃ to obtain high-temperature material A; add fluorescent material to the above-mentioned high-temperature material A, banbury for 20 minutes to 160 ℃, obtain fluorescent sheath material, and set aside;

[0041] Preparation of luminous grounding wire: extrude the grounding wire body and the above fluorescent sheath material through a twin-screw extruder, then spray codes with a laser printer in turn, adjust the tension th...

Embodiment 2

[0043] A luminous grounding wire includes a grounding wire body, the grounding wire body includes a copper core and an insulating sheath wrapping the copper core, the insulating sheath is wrapped with a fluorescent sheath, and the luminous grounding wire is processed by the following processing steps:

[0044] Prepare the fluorescent sheath material: Add polyvinyl chloride resin, ethylene-vinyl acetate copolymer, toughening agent, antioxidant and coupling agent into the internal mixer according to the addition amount in Table 1 and mix for 13 minutes to 158 ℃ to obtain high-temperature material A; add fluorescent material to the above-mentioned high-temperature material A, banbury for 26 minutes to 167 ℃, obtain fluorescent sheath material, and set aside;

[0045] Preparation of luminous grounding wire: extrude the grounding wire body and the above fluorescent sheath material through a twin-screw extruder, then spray codes with a laser printer in turn, adjust the tension throug...

Embodiment 3

[0047] A luminous grounding wire includes a grounding wire body, the grounding wire body includes a copper core and an insulating sheath wrapping the copper core, the insulating sheath is wrapped with a fluorescent sheath, and the luminous grounding wire is processed by the following processing steps:

[0048] Preparation of fluorescent sheath material: Add polyvinyl chloride resin, ethylene-vinyl acetate copolymer, toughening agent, antioxidant and coupling agent into the internal mixer according to the addition amount in Table 1 and mix for 17 minutes to 164 ℃, to obtain high-temperature material A; add fluorescent material to the above-mentioned high-temperature material A, banbury for 30 minutes to 172 ℃, obtain fluorescent sheath material, and set aside;

[0049] Preparation of luminous grounding wire: extrude the grounding wire body and the above fluorescent sheath material through a twin-screw extruder, then spray codes with a laser printer in turn, adjust the tension th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com